Measuring method and measuring system and machine for detecting the position of an object

A measurement method, measurement system technology, applied in application, food science, tobacco, etc., to achieve the effect of avoiding object damage and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

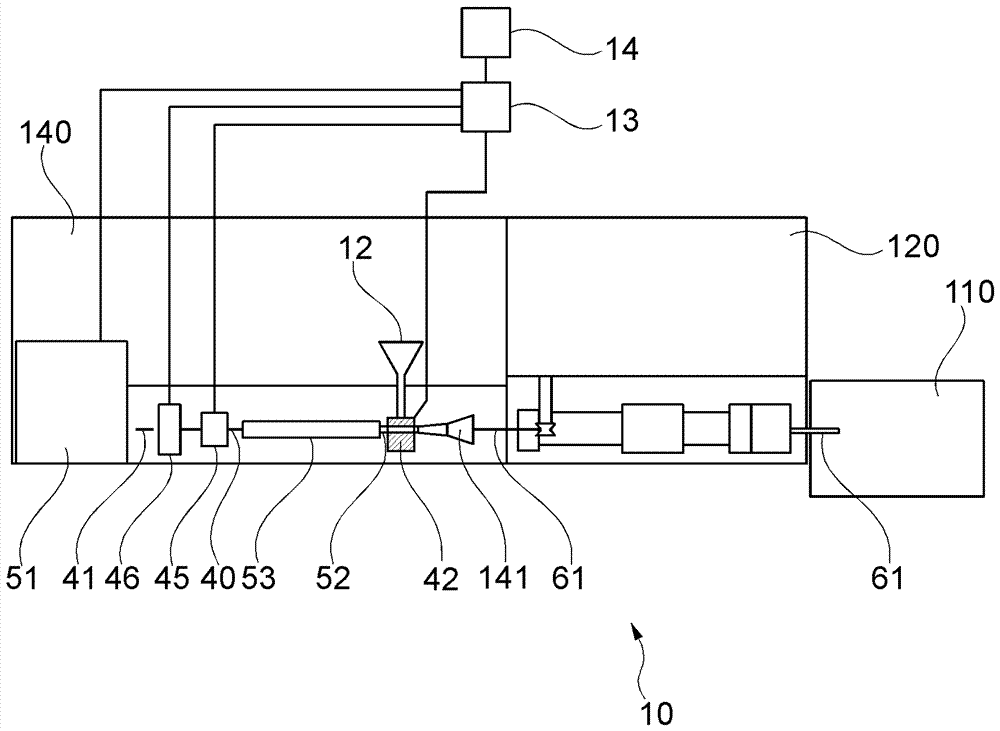

[0020] according to figure 1 The filter rod production machine 10 comprises a filter tow processing unit 120 and a filter rod forming machine 140 next to it. In the treatment unit 120 , after the filter tow band 61 has been withdrawn from the filter tow bundle 110 , it is stretched, unrolled and sprayed with a softener, such as triacetin. The material web 61 unrolled in this way is then fed to the filter rod forming machine 140 , in particular via an inlet funnel 141 . Arranged in the filter rod forming machine 140 is a forming device or bong device (Formatvorrichtung) 53 , which is wrapped with a filter tow band 61 by means of a wrapping band, not shown, drawn from a reel. To form a filter rod 40.

[0021] An embedding mechanism 42 for embedding flavor-filled capsules removed from the reservoir 12 into the material web 61 is arranged between the inlet funnel 141 and the forming device 53 . The engagement means 42 can be designed differently, for example as an engagement wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com