Method for decoloring waste sugar liquid generated by dried fruit processing

A technology for sugar liquid and dried fruit, which is applied in the field of decolorizing waste sugar liquid from dried fruit processing, can solve problems such as poor effect, and achieve the effects of being beneficial to production operation, low cost and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The percentages involved in the present invention are all mass percentages.

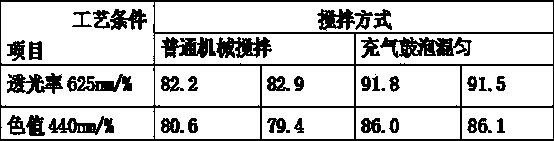

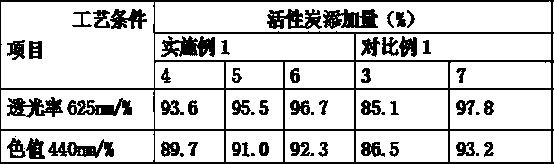

[0015] The present invention is further described below through examples and comparative examples, and the decolorization effect of dried fruit processing waste sugar liquid is recorded under different production conditions.

[0016] A method for decolorizing the waste sugar liquid of dried fruit processing, comprising the following steps:

[0017] 1. Dilute the dried fruit processing waste sugar solution to a concentration of 30%-40% sugar solution, heat the diluted sugar solution to 40°C-45°C, and then add 0.5‰ of compound pectinase for enzymatic hydrolysis for 40min. After enzymolysis, heat to 85°C for more than 5min to inactivate pectinase, then cool to 60°C and add 60g-100g / hl bentonite flocculant to flocculate impurities such as colloids in the sugar solution;

[0018] 2. Take the supernatant liquid from the sugar solution processed in step 1, add 5% wet activated carbon (50% moisture c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com