Nibea albiflora feed and preparing method of nibea albiflora feed

A technology for croaker and feed, which is applied to animal feed, animal feed, climate change adaptation, etc., can solve the problems of low nutritional value and poor palatability of croaker feed, so as to facilitate feeding and growth, improve taste and supplement nutrition The effect of ingredients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

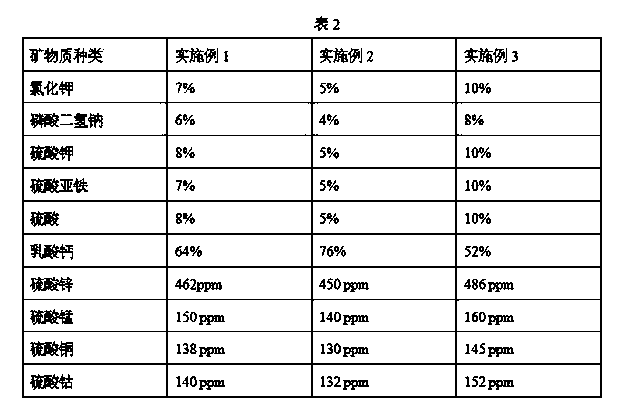

[0032] By weight, weigh 40 parts of soybean meal, weigh 20 parts of corn gluten powder, weigh 35 parts of high-gluten flour, weigh 0.6 part of choline chloride, weigh 2.3 parts of multivitamins according to the ratio in Table 1, and weigh 2.3 parts according to Table 2. Take 2.4 parts of compound minerals by weighing, and weigh 0.3 parts of compound enzyme preparation according to the ratio in Table 3, as nutritional components. The powdery nutritional components are passed through a 80-mesh sieve. Take 100.6 parts of unfrozen miscellaneous fish or minced fish that have died for no more than 1 day as fresh miscellaneous fish, grind them into surimi with a meat grinder, mix the nutrient components and surimi into a feed mixer, and add solid total Add 25% water and stir well. Use high-pressure steam to carry out pre-sterilization treatment at 121° C. for 20 minutes on the evenly stirred feed, then add 50 ppm of Rhodospirillum, and use a soft pellet feed press to press into soft...

Embodiment 2

[0034] By weight, weigh 35 parts of soybean meal, weigh 15 parts of corn gluten powder, weigh 30 parts of high-gluten flour, weigh 0.5 part of choline chloride, weigh 1.5 parts of multivitamins according to the ratio in Table 1, and weigh 1.5 parts according to Table 2. 1.5 parts of compound minerals are weighed according to the ratio, and 0.2 parts of compound enzyme preparation are weighed according to the ratio in Table 3 as nutritional components. The powdery nutritional components are passed through a 50-mesh sieve. Take 125.6 parts of unfrozen miscellaneous fish or minced fish that have died for no more than 1 day as fresh miscellaneous fish, grind them into surimi with a meat grinder, mix the nutrient components with the surimi and pour them into the feed mixer, and add solid total Add 20% water and stir well. The evenly stirred feed was sterilized at 120° C. for 15 minutes by high-pressure steam, and then 10 ppm of Rhodospirillum was added, and pressed into soft pelle...

Embodiment 3

[0036] By weight, weigh 45 parts of soybean meal, weigh 25 parts of corn gluten powder, weigh 40 parts of high-gluten flour, weigh 0.8 part of choline chloride, weigh 3 parts of multivitamins according to the ratio in Table 1, and weigh 3 parts according to Table 2. Take 3 parts of compound minerals according to the proportion, and weigh 0.4 part of compound enzyme preparation according to the proportion in Table 3, as a nutritional component. The powdery nutrient components are passed through an 80-mesh sieve. Take 117.2 parts of unfrozen miscellaneous fish or minced fish that have died for no more than 1 day as fresh miscellaneous fish, grind them into surimi with a meat grinder, mix the nutrient components and surimi into a feed mixer, and add solid total Add 30% water and stir well. Use high-pressure steam to carry out pre-sterilization treatment at 125° C. for 18 minutes on the evenly stirred feed, then add 100 ppm of Rhodospirillum, and use a soft pellet feed press to p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com