Winding battery plate group and preparation method thereof

A battery pole group and pole group technology, which is applied in winding/folding electrodes, secondary battery manufacturing, secondary batteries, etc., can solve the problems of easy tearing, insufficient strength, and poor shock resistance of batteries, so as to improve the shock resistance , Easy to operate, guaranteed quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described through the embodiment of a 75Ah winding battery.

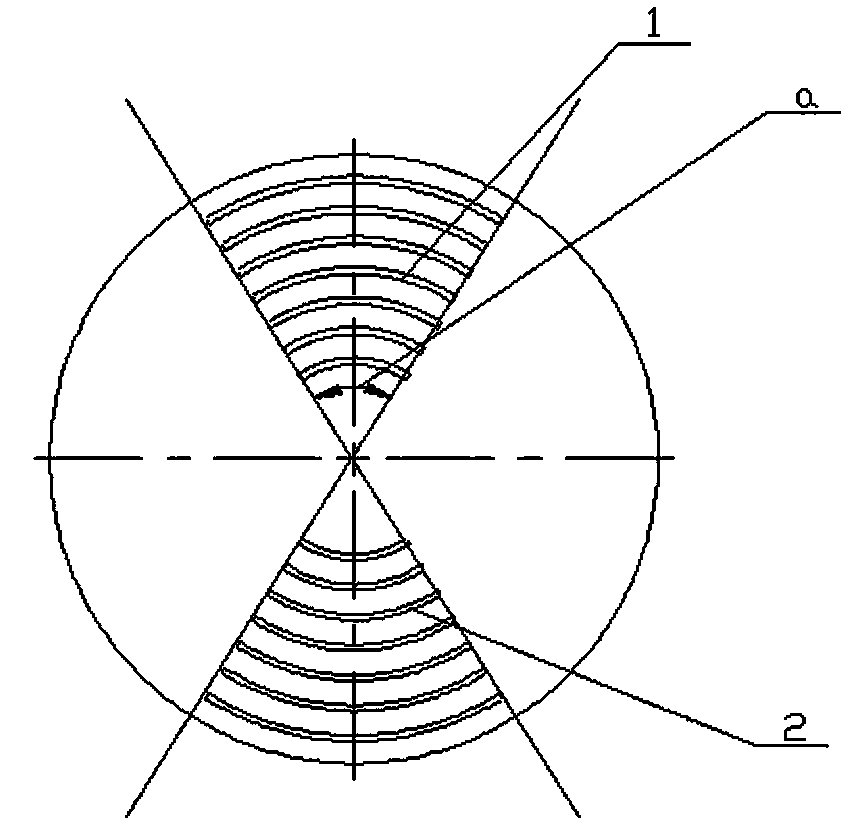

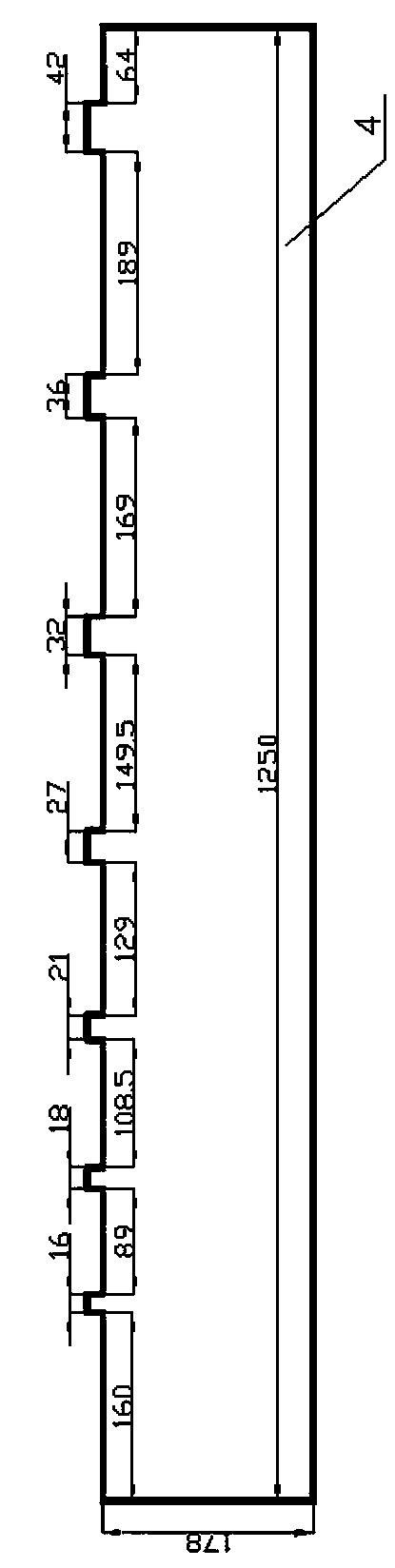

[0017] see figure 1 , in the electrode group of the wound battery, the positive electrode ear 1 and the negative electrode ear 2 are symmetrically distributed, and the centerlines of the two are located on the same diameter of the end face of the electrode group. α=60 0 . The expanded dimensions of the positive and negative grids in the pole group are as follows figure 2 , image 3 shown.

[0018] The method of making the pole group is as follows:

[0019] 1. Set the total length of the positive grid 3 and the negative grid 4 to 1250mm, the total width to 178+ lug height 13mm according to the existing process, and determine the center line positions of the 7 tabs on the positive and negative grids;

[0020] 2. Calculate the corresponding α=60 on each winding circle of the pole group 0 The arc length is the width of the 7 positive and negative tabs from the inside ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com