Horizontal high-tonnage energy-saving fatigue experiment device

A technology for saving energy and fatigue experiments, applied in the direction of applying repeated force/pulsation force to test the strength of materials, etc., can solve the problems of low experiment frequency, high energy consumption, and long fatigue test cycle, and achieve the effect of energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

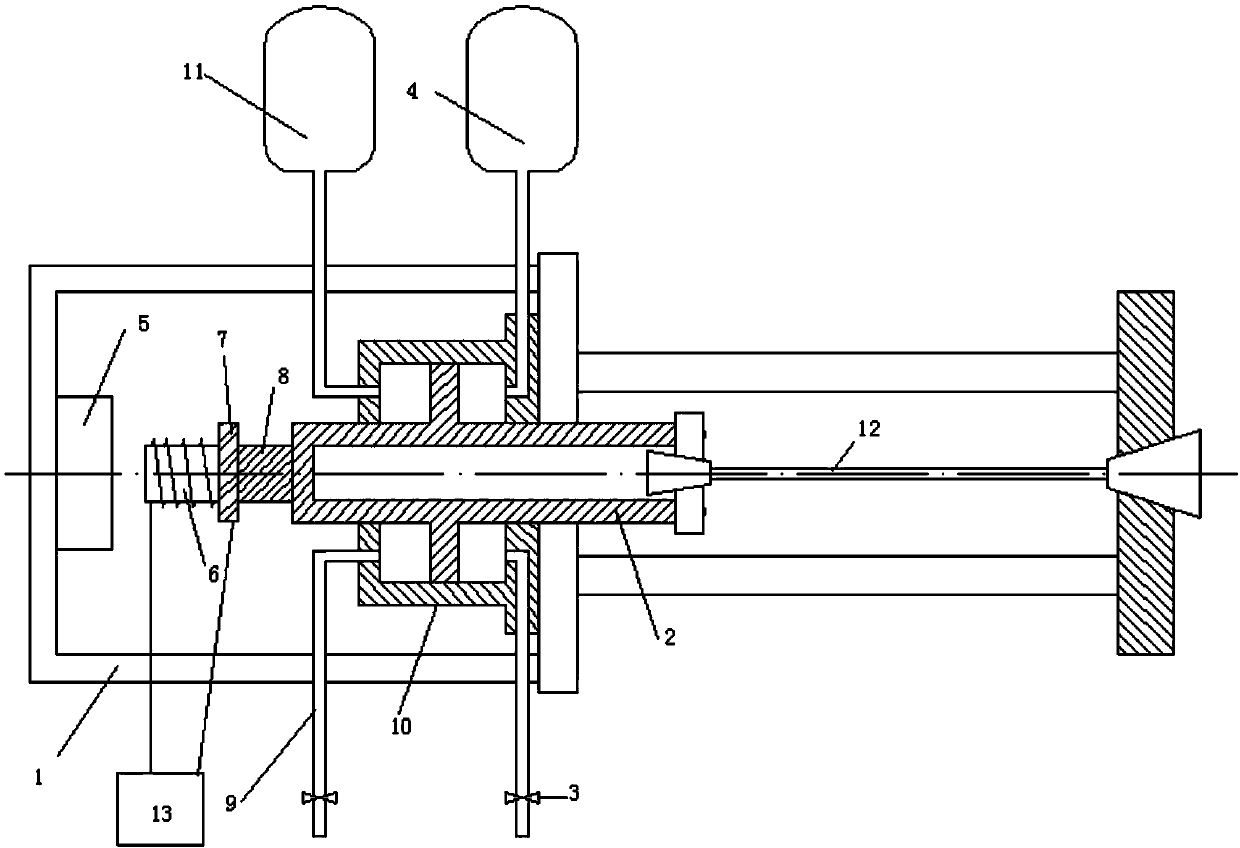

[0021] Taking the 1000t fatigue testing machine as an example, carry out the 800±100t fatigue experiment, that is, the fatigue experiment of 800t average load and 100t sinusoidal pulsating load.

[0022] If a traditional dynamic fatigue testing machine is used, it is assumed that the required displacement of the actuator loaded from 700t to 900t is l , the cross-sectional area of the cylinder of the 1000t testing machine is A , then the hydraulic oil flow required for each loading cycle is Q= lA . Calculated according to the design frequency of 1Hz and displacement of 1mm, the required hydraulic source motor power is about 500kw.

[0023] If the dynamic fatigue testing machine designed by the present invention is used, the tonnage is used as an electromagnetic loading device of 100t. During the fatigue test, ±100t loading is carried out on the basis of an average load of 800t.

[0024] Firstly, the sample 12 is loaded on the bracket, and the loading end of the cylinder pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com