Embedded intelligent milling duplication eliminating balance measuring system based on OMAP

An embedded system and measurement system technology, applied in the field of weight removal and balance measurement devices in milling, can solve the problems of low measurement accuracy, low integration, weak anti-interference ability, etc., and achieve rich on-chip resources and large storage capacity , Functionally scalable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

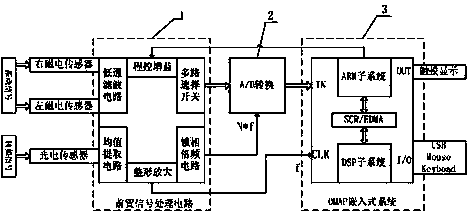

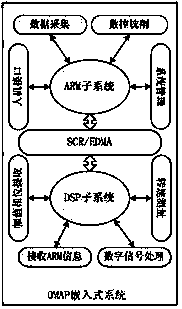

[0010] The present invention is composed of a signal conditioning circuit 1, an A / D conversion system 2 and an OMAP embedded system 3. The signal conditioning circuit 1 is composed of left and right magnetoelectric sensors, a signal conditioning circuit, a photoelectric sensor, an average extraction circuit, and a pulse shaping circuit. Composed of a phase-locked frequency multiplication circuit, the left and right magnetoelectric sensors convert the mechanical vibration signal into a voltage signal, and filter, amplify, and multiplex through the signal conditioning circuit, and the photoelectric sensor collects the phase reference signal. The shaping circuit and the phase-locked frequency multiplication circuit are processed, and the A / D conversion system 2 performs A / D conversion on the output signal of the pre-signal processing circuit under the action of the N multiplier pulse signal; the OMAP embedded system 3 is composed of the ARM core and The DSP chip is composed of dua...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com