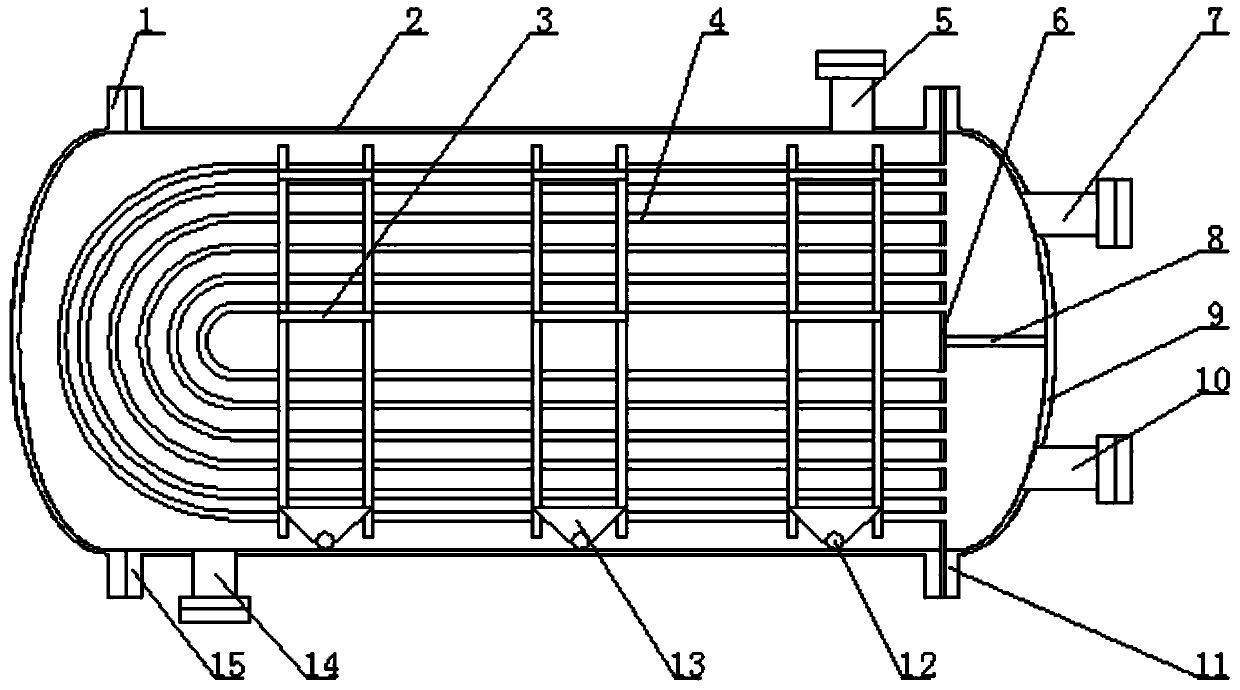

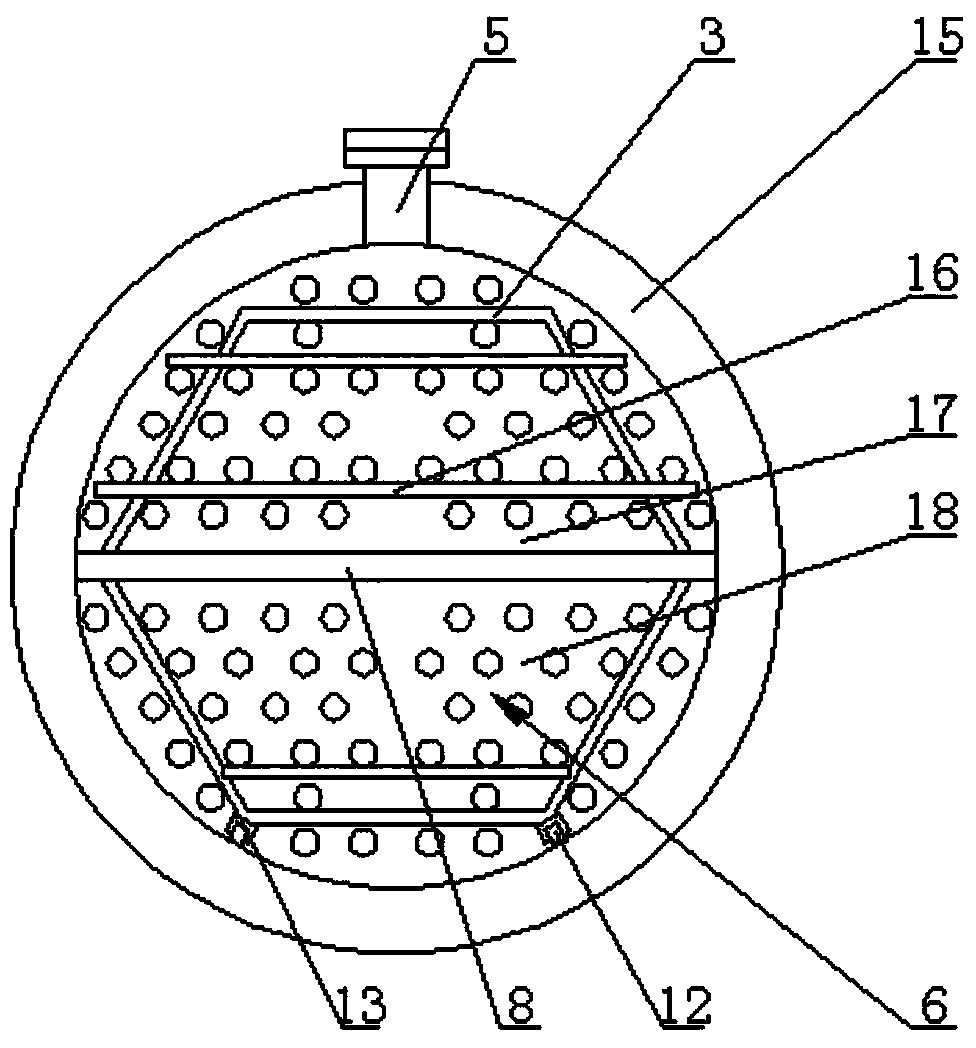

Shell and tube type sewage heat exchanger convenient to clean

A shell-and-tube heat exchanger technology, applied in the direction of the heat exchanger shell, indirect heat exchanger, heat exchanger type, etc., can solve the problem of large pressure-bearing area, reduced heat exchange area, and easy leakage of the cleaning door and other problems, to achieve the effect of easy cleaning, improving heat transfer efficiency and reducing dead zone

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] A heat exchange system, which has a structure including multiple shell and tube sewage heat exchangers 21, a water source heat pump unit 24, and a heating device 22. The water source heat pump unit is connected to a plurality of heat supply units connected in parallel through a hot water circulating pump 23 Equipment, the water outlet end of the other end of the water source heat pump unit is connected in parallel to the clear water inlets 10 of all shell and tube sewage heat exchangers through the clean water circulation pump 25, and the water inlet end of the other end of the water source heat pump unit is connected in parallel to all shells The clean water outlet 7 of the tubular sewage heat exchanger, the sewage inlet 5 of all shell and tube sewage heat exchangers are connected in parallel and connected to the sewage source 27 through the sewage pump 26, and the sewage outlet 14 of multiple shell and tube sewage heat exchangers Connect the sewage source after being co...

Embodiment 2

[0054] A heat exchange system, which has a structure including multiple shell and tube sewage heat exchangers 21, a water source heat pump unit 24, and a heating device 22. The water source heat pump unit is connected to a plurality of heat supply units connected in parallel through a hot water circulating pump 23 Equipment, the outlet end of the other end of the water source heat pump unit is connected to the clear water inlet 10 of the first shell and tube sewage heat exchanger through the clean water circulation pump 25, and the inlet end of the other end of the water source heat pump unit is connected to the last shell tube The clean water outlet 7 of the type sewage heat exchanger is connected to the clean water outlet of each shell and tube sewage heat exchanger from the first shell and tube sewage heat exchanger to the last shell and tube sewage heat exchanger. The clean water inlet of a shell and tube sewage heat exchanger, from the last shell and tube sewage heat exchan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com