Tolerance compensation apparatus

A technology of equipment and tolerance, applied in the field of equipment for tolerance compensation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

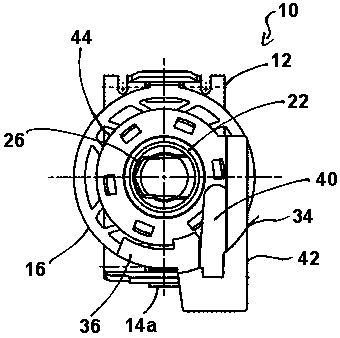

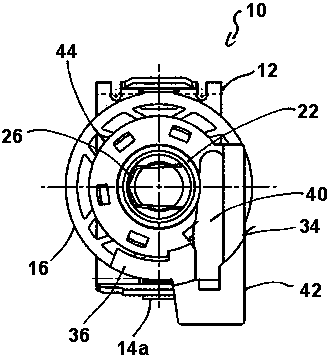

[0035] figure 1 A first embodiment of a tolerance compensation device 10 for compensating tolerances between a first component (not shown) and a second component (not shown) is shown in .

[0036] The tolerance compensation device 10 comprises a snap-in nut 12 made of spring steel and by means of said snap-in nut the tolerance compensation device 10 can be fastened to the first component. In the illustrated embodiment, the snap-in nut 12 is positioned at the lower side of the tolerance compensation device 10 . The snap-in nut 12 comprises a nut element (not shown) for screwing onto a screw element (eg a screw or a threaded bolt) extending through the tolerance compensation device 10 .

[0037] The snap-in nut 12 is suspended at two fastening hooks 14a, 14b ( figure 2 ), said hook is molded onto the fastening ring 16 of the tolerance compensation device 10 ( figure 1 ). The fastening ring 16 is fixedly connected to a base element 18 which is hollow cylindrical and has an i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com