Packing box

A packing box and packing technology, which is applied in wellbore/well components, earthwork drilling, sealing/isolation, etc. It can solve problems such as increased workload, increased maintenance costs, sand stuck or wax stuck accidents, etc. , to achieve the effect of prolonging service life, reducing labor load and saving electric energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

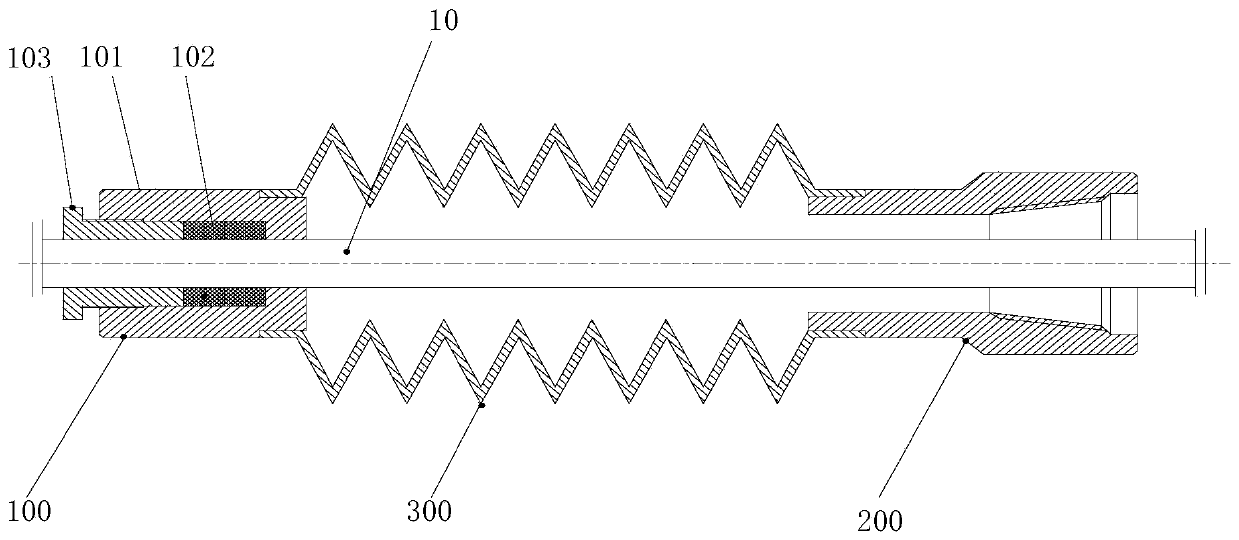

[0017] Such as figure 1 As shown, the present invention provides a packing box, the packing box includes:

[0018] The upper fixed sealing part 100 for fixing on the polished rod 10, the upper fixed sealing part 100 includes a sealing packing box 101 that can be sleeved on the polished rod 10, and a sealing packing box set in the sealing packing box 101 102 and a pressing cap 103 capable of compressing the sealing packing 102 in the sealing packing box 101 so that the sealing packing 102 and the polished rod 10 are hermetically fixed;

[0019] The lower joint 200 used to connect with the wellhead Christmas tree;

[0020] And, the telescopic sleeve 300 that can expand and contract between the upper fixed sealing pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com