Downhole pressurizer and downhole pressurization method

A technology of supercharger and pressure fluid, which is applied in the direction of drilling with liquid/gas jets, etc., can solve the problems of speeding up drilling machinery, not being able to be widely used, and having a short service life, so as to improve the drilling speed, reduce investment, and prevent The effect of hard impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

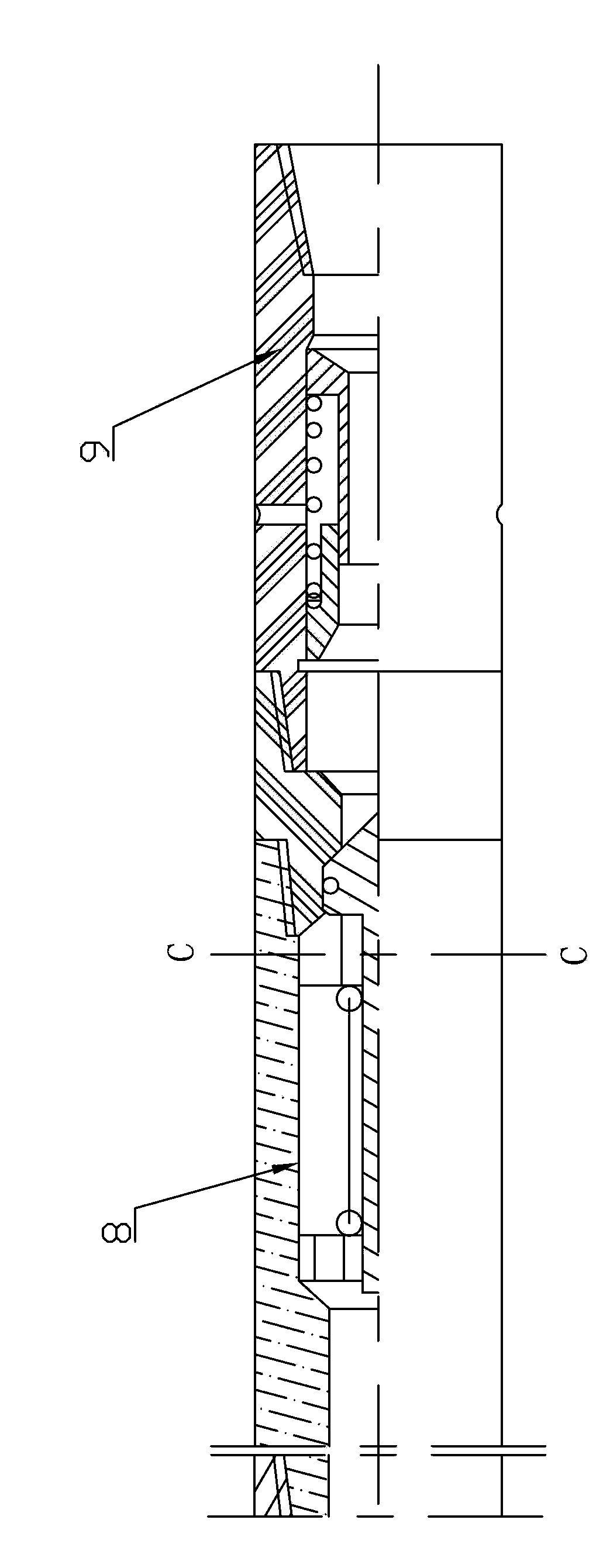

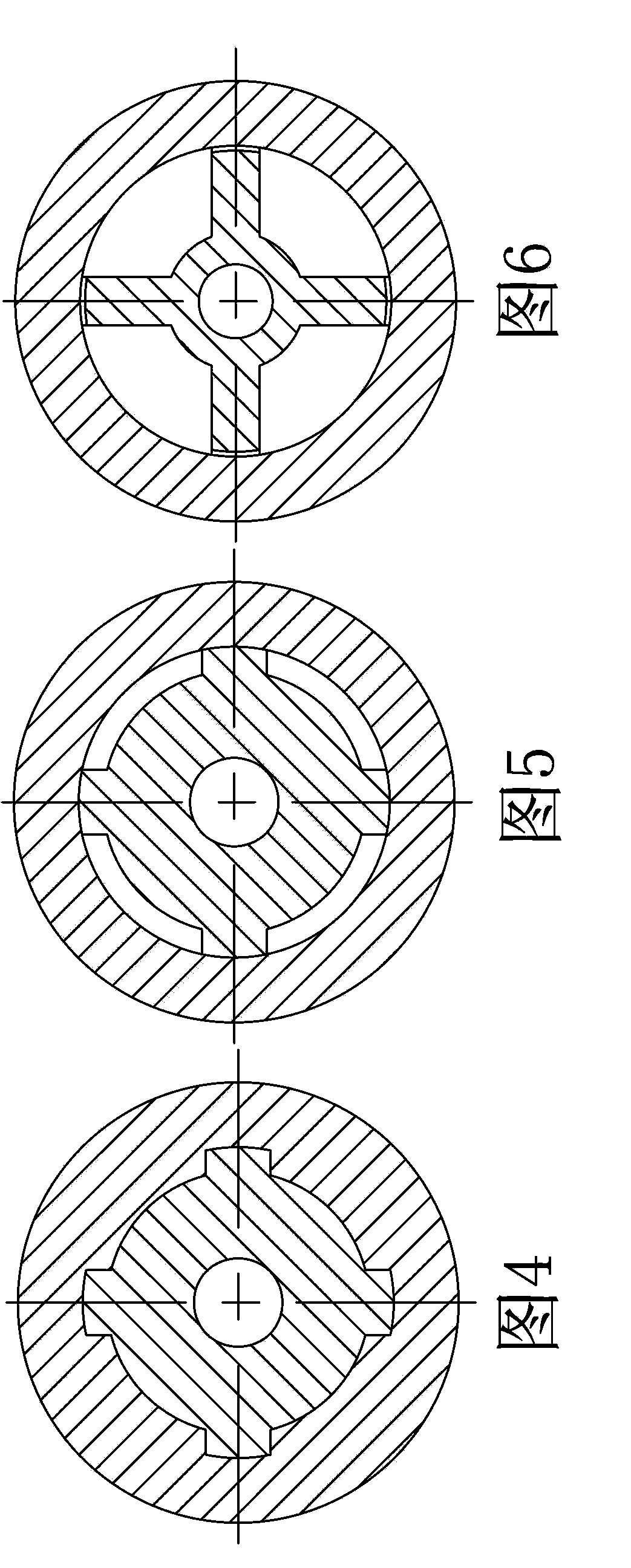

[0032] like figure 1 , figure 2 , image 3 As shown, a bottom hole booster provided by the present invention at least includes: a check valve 8, an upper joint 7 connected to the lower end of the check valve 8, an outer cylinder fixedly connected to the lower end of the upper joint 7 4. The spline joint 3 fixedly connected to the lower end of the outer cylinder 4, the hollow mandrel 2 whose upper end is slidably connected to the inner wall of the outer cylinder 4 through the hollow piston 5 (the sliding stroke is generally 3-5 meters), and the The lower joint 1 connected to the lower end of the mandrel 2 and the spring 6 arranged in the outer cylinder 4 and between the upper joint 7 and the piston 5 . Among them, such as figure 1 As shown, the splined joint 3 and the outer cylinder 4 are in sliding connection with the mandrel 2 .

[0033] During installation, the upper end of the check valve 8 can be connected to the drilling tool through the bypass valve 9, and the lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com