Ship docking device

A technology for leaning against a ship and against a ship column, which is applied to ships, shipping equipment, climate change adaptation, etc., can solve the problems of high maintenance and update costs, high engineering costs, and a large number of rubber fenders, so as to save engineering costs and reduce costs. The effect of maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

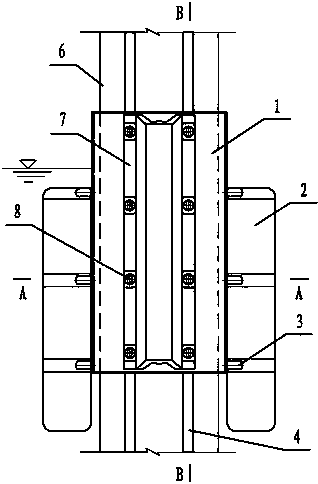

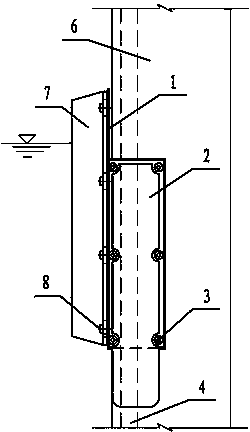

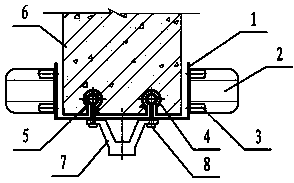

[0021] Such as figure 1 as well as figure 2 As shown, the berthing device includes a berth column located at the waterside of the wharf, a rubber fender and a floating body floating in the water body on one side of the berth column. The buoyant body can slide up and down and is connected to the berth column; Connected, the rubber fender keeps its top surface above the water surface under the action of the buoyancy of the buoyancy body. The floating body includes a connecting plate 1, a buoyant tank 2 with a cavity inside, a chute 41 is arranged longitudinally inside the anchor column, and a sliding part 5 is built in the chute, and a strip-shaped connection port 42 is arranged longitudinally on the side of the chute facing the water body , the connecting plate is fixedly connected with the sliding member 5 through a number of rubber fender anchors 8 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com