Long-chain dibasic acid production strain and its preparation method and application

A technology for producing long-chain dibasic acids and strains, which is applied in biochemical equipment and methods, methods based on microorganisms, microorganisms, etc., and can solve the problems of insignificant effect of long-chain dibasic acids, and achieve enhanced tolerance and fermentation The effect of shortening the cycle and increasing the conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

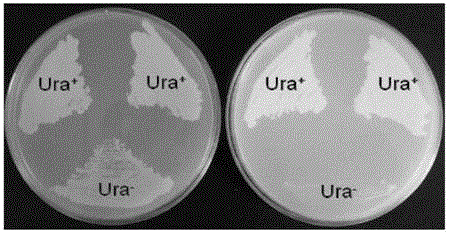

[0035] Example 1: Metabolic Engineering Transformation of Bacterial Strains

[0036] 1) Genome sequencing

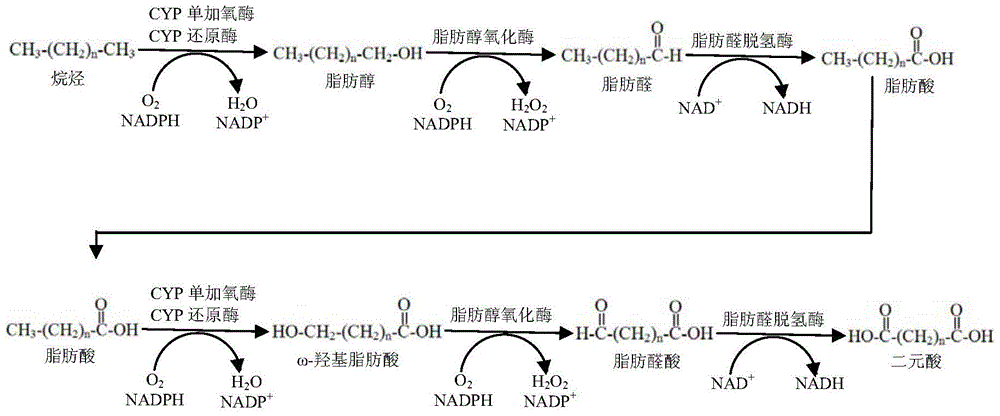

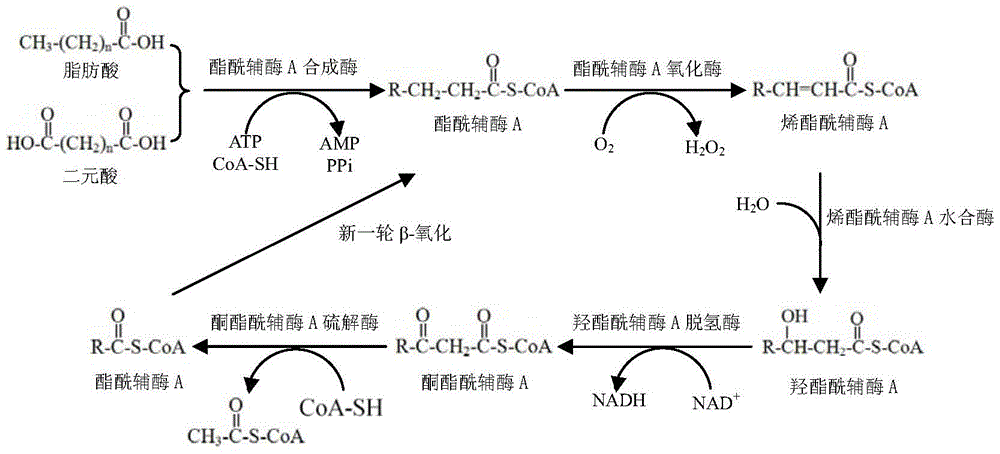

[0037] Genomic DNA of the long-chain dibasic acid-producing strain Candida was prepared using the Yeast DNAiso Kit of Bao Bioengineering Co., Ltd., and the specific operation was carried out according to the kit instructions. Genomic DNA is then subjected to steps such as library construction, next-generation sequencing technology sequencing analysis, and data assembly. Through genome annotation and data analysis, the gene information related to dibasic acid production of the production strain was obtained, and the coding sequences of genes related to the ω-oxidation and β-oxidation metabolic pathways of the strain were mined. For yeast, β-oxidation mainly occurs in the peroxisome, especially the β-oxidation of long-chain fatty acids, which only occurs in the organelle of peroxisome. In the ω-oxidative metabolic pathway, alkanes undergo a three-step enzymatic reaction ...

Embodiment 2

[0064] Embodiment 2: Fermentative production of long-chain dibasic acid

[0065] After the strains are cultured on a conventional slant, they are inserted into 50ml primary seeds and cultivated for 16 hours, and then the primary seeds are transferred to 500ml secondary seeds for 16 hours.

[0066] The formula of seed medium: yeast extract 1-8g / L, corn steep liquor 1-8g / L, sucrose 5-25g / L, KH 2 PO 4 4-12g / L, urea 0.5-4g / L, heavy wax 40-70g / L, sterilized at 121°C for 30 minutes. Among them, the sucrose and urea are separately sterilized at 110° C. for 20 minutes, and then combined and mixed evenly after sterilization.

[0067] After the secondary seed fermentation is completed, it is transferred into a 5L fermenter. Fermentation tank medium formula: yeast extract 1-8g / L, corn steep liquor 1-8g / L, sucrose 5-30g / L, KH 2 PO 4 4~15g / L, urea 0.5~4g / L, KNO 3 5~15g / L, NaCl 0.5~2.5g / L, sterilized at 121°C for 30 minutes. Among them, sucrose and urea are sterilized separately, ste...

Embodiment 3

[0072] According to the method of embodiment 2, just substrate is changed into methyl laurate from dodecyl straight-chain alkane.

[0073]

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com