A laboratory double distilled water device

A technology of double distilled water and laboratory, applied in the field of laboratory equipment, can solve the problem of insufficient comprehensive utilization rate, and achieve the effect of avoiding clutter, simplifying operation steps and reducing material consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

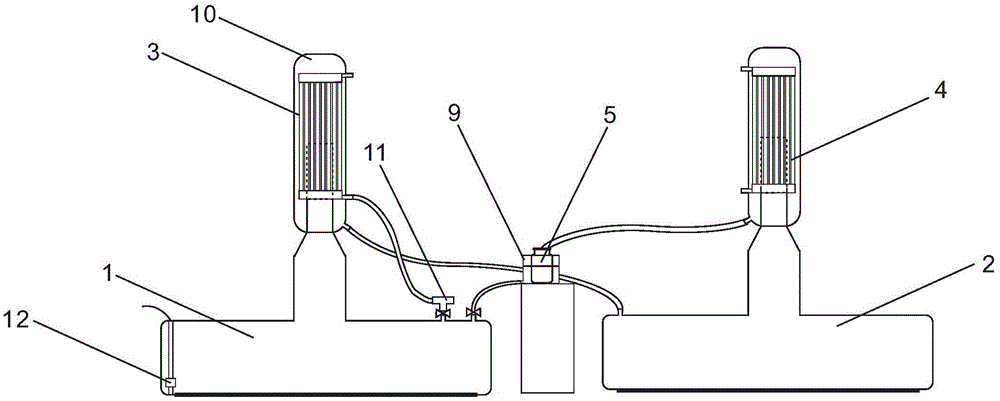

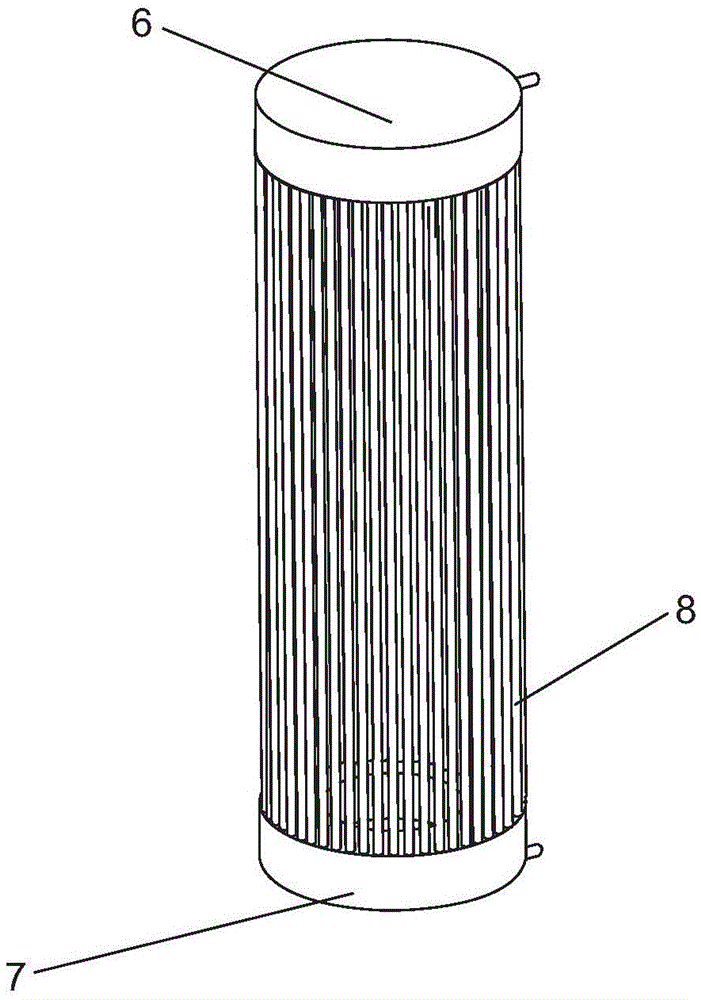

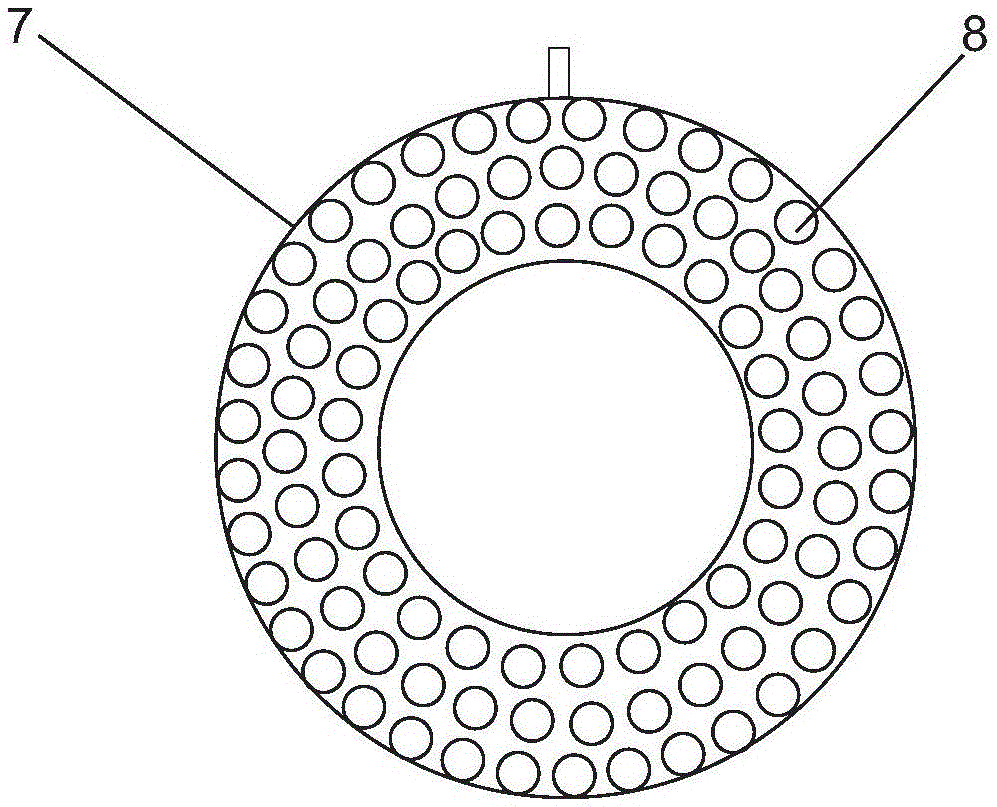

[0021] Such as figure 1 Shown, a kind of laboratory twice distilled water device, comprises the first distillation bottle 1, the second distillation bottle 2, the first condensation pipe 3, the second condensation pipe 4 and the collecting bottle 5, the first distillation bottle 1 and the second distillation Bottles 2 are equipped with a water inlet and a steam outlet, wherein the first distillation bottle 1 has two water inlets, and the first condensation pipe 3 and the second condensation pipe 4 are respectively connected and docked with the first distillation flask 1 and the second distillation flask 2 , the first condensing pipe 3 and the second condensing pipe 4 have the same shape, and both have three orifices of cooling water inlet, cooling water outlet and distilled water outflow port, and the cooling water inlet, cooling water outlet and distilled water outflow port are sequentially from top to bottom Set, the outlet of distilled water is located near the bottom of ea...

Embodiment 2

[0024] The three-way joint is communicated with the cooling water outlet of the second distillation bottle 2, and there are eighty water flow pipes 8. All the other are with embodiment 1.

Embodiment 3

[0026] The water inner pipe is a serpentine spiral pipe, and the three-way joint 11 is connected to the water adding control valve while only communicating with the water outlet of the water bath dish 9 through a silicone tube, not connected to the cooling of the first distillation bottle 1 or the second distillation bottle 2 In the water outlet, the liquid level sensor 12 is not arranged in the first distillation bottle 1 either. The water adding control valve is a manual valve. All the other are with embodiment 1. During the distillation process, the replenishment of the first retort 1 is manually controlled. When the water level in the first retort 1 is very low or when the water temperature in the water bath 9 is close to 20° C., the water addition control valve can be manually operated to replenish water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com