Gas bag capable of autoinflation underwater

A technology of automatic inflation and air bag, applied in the field of air bag, which can solve the problems of long cycle, high cost and high risk.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

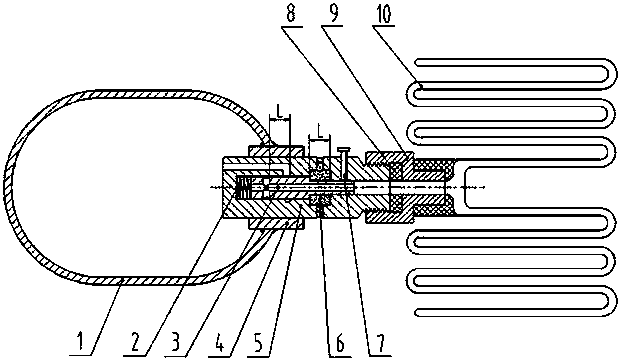

[0007] As shown in the accompanying drawings, it is a specific embodiment of the air bag that can be automatically inflated underwater according to the present invention. Including: gas cylinder shell (1), spring (2), valve inner nozzle (3), reinforcement sleeve (4), valve jacket (5), positioning groove (6), top wire (7), sealing ring (8) , screw sleeve (9) and air bag (10).

[0008] Among them, the gas cylinder casing (1) is welded with steel plates, and a reinforcing sleeve (4) is welded at the valve where the gas enters and exits.

[0009] The deflation valve is made up of a valve overcoat (5) and a valve inner mouth (3), and the outermost end of the valve overcoat (5) has threads for connecting the air bag (10). The accompanying drawing shows the state that the inside of the gas cylinder is filled with high-pressure gas and the air bag (10) is not inflated. At this time, the inside of the positioning groove (6) is filled with a whole piece of edible rock sugar or other no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com