Subway washing aerial work comprehensive vehicle

A technology of aerial work and aerial work platform, applied in the direction of spraying vehicles, etc., can solve the problems of limited space, stable tunnel, facilities in the tunnel, adverse influence of the water environment around the tunnel for driving safety, water leakage from the tunnel wall, etc., and achieve a reasonable layout. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

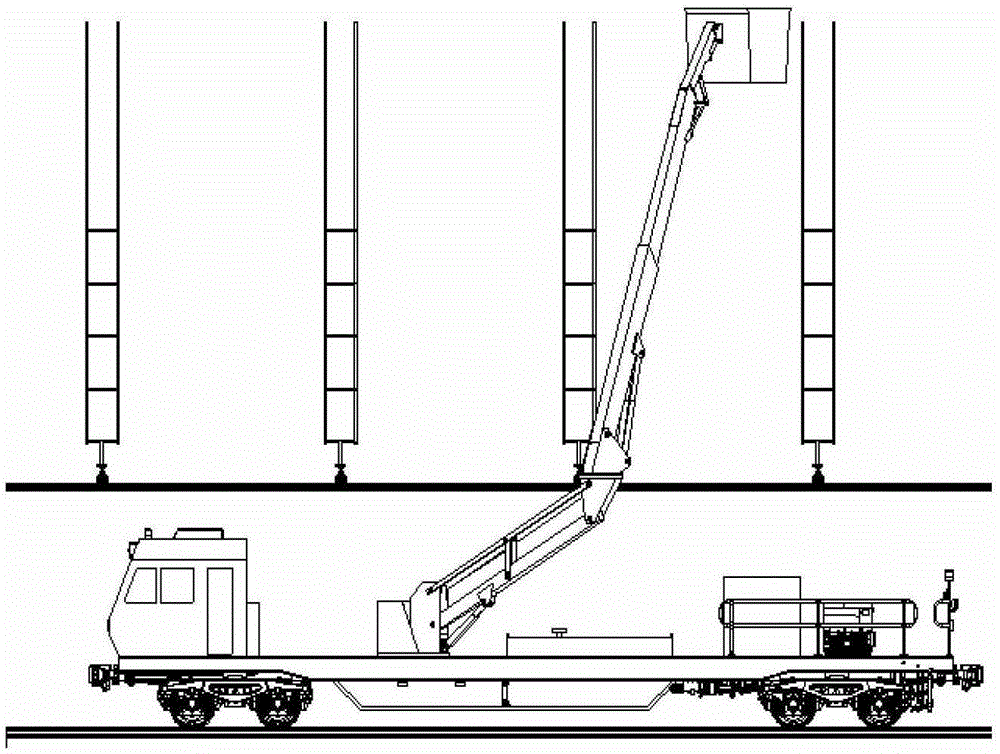

[0021] figure 1 In , the overall layout of the present invention is described, which is the transportation state of the whole vehicle in the tunnel and meets the boundary requirements of the subway. It includes a rail vehicle 1 with its own power. The car body is a double-layer structure with double fish belly. The upper part of the car body is equipped with a crank arm double turntable aerial work platform 2. 3 is connected, and a high-pressure water system 4 is installed at the lower part of the car body, and the high-pressure water system 4 is connected with the spray rod 4-5 through a high-pressure water pipe; the power system 3 and the high-pressure water system 4 are all connected with the control device.

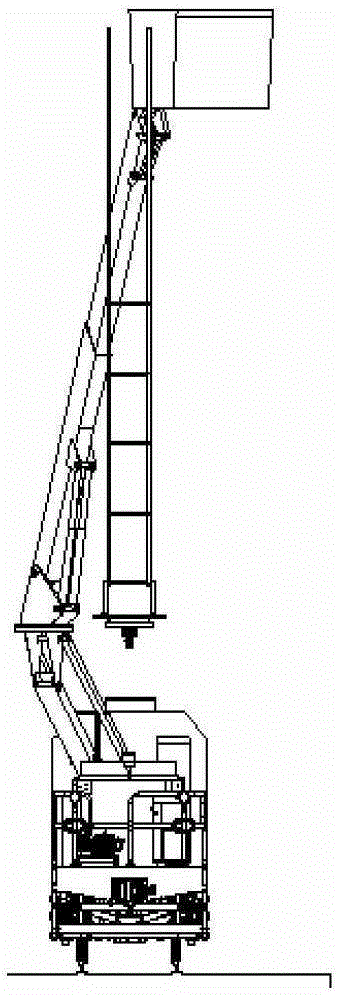

[0022] figure 2 , Figure 2a In the above, the state of the vehicle working at heights is described. The aerial work platform bypasses the catenary and re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com