Disassembling device of circuit board with components and parts and disassembling method of disassembling device

A component and circuit board technology, which is applied to the dismantling device and its dismantling field of circuit boards with components, to achieve the effects of no secondary pollution discharge, large processing capacity, and guaranteed automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be further described below in conjunction with specific embodiments. The following examples are not intended to limit the present invention.

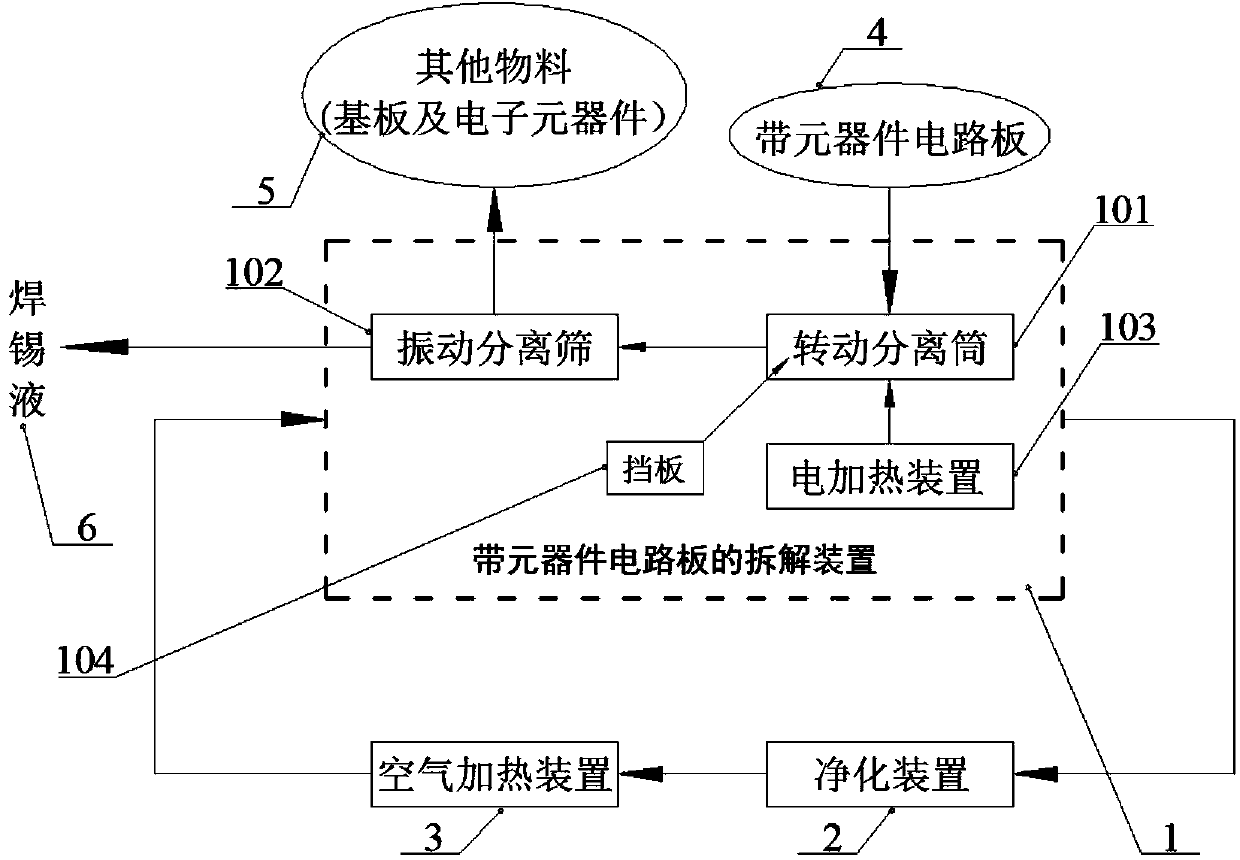

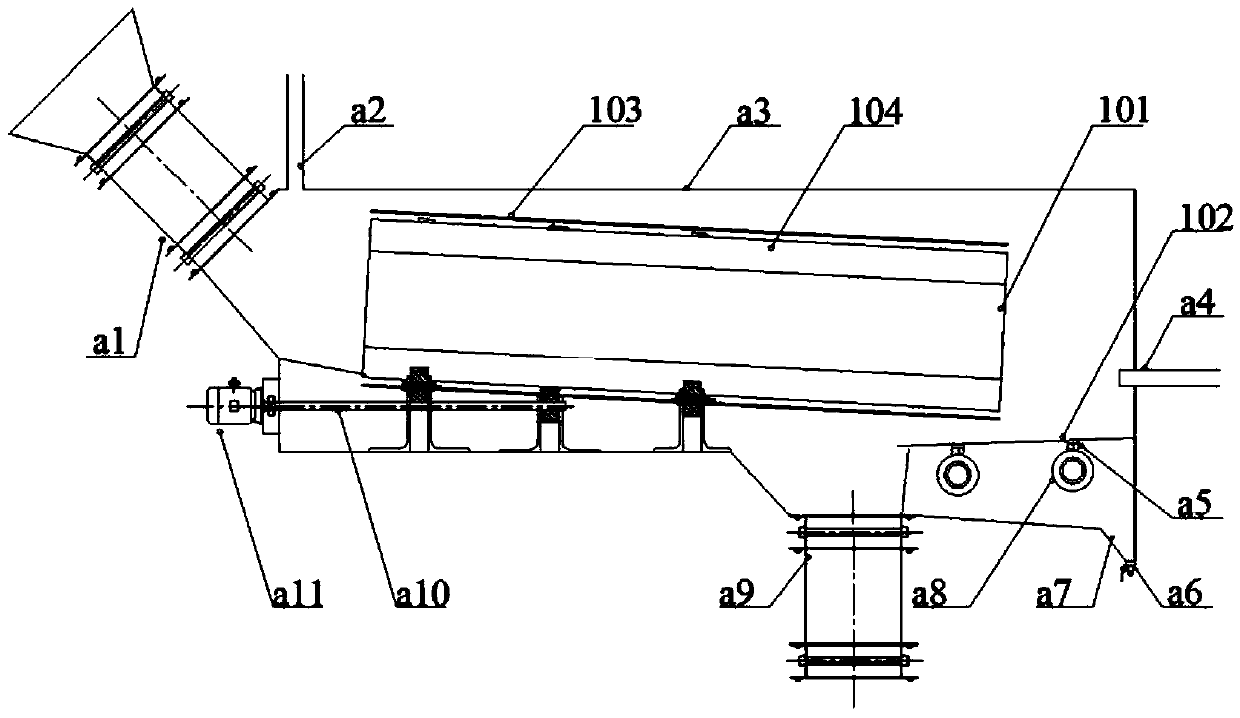

[0051] The present invention heats and desolders circuit boards with components through the combination of electric heating and hot air heating methods, and controls and ensures the uniformity of temperature distribution inside the automatic dismantling device; The combination of the board and the vibrating separation screen provides the circuit board with components with the required disassembly force and the power to move to the discharge end, ensuring the efficient disassembly and smooth discharge of the circuit board with components; The hot air discharged through the air outlet is purified and dust-removed, and then enters the air heating device to be heated again to become hot air under the required working conditions, and then introduces the automatic dismantling device to continue working and re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com