Brake thread head device and forming method

A technology of brake device and brake line, which is applied in the field of brake line head device and forming, can solve the problems of uneven thickness, collapse, fracture, and missing, etc., and achieve the effect of not easy to collapse and fracture, and excellent practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Regarding the technology, means and effects thereof adopted in the present invention, a preferred embodiment is given in detail in conjunction with the accompanying drawings. It is believed that the above-mentioned purpose, structure and characteristics of the present invention should be understood in depth and specifically .

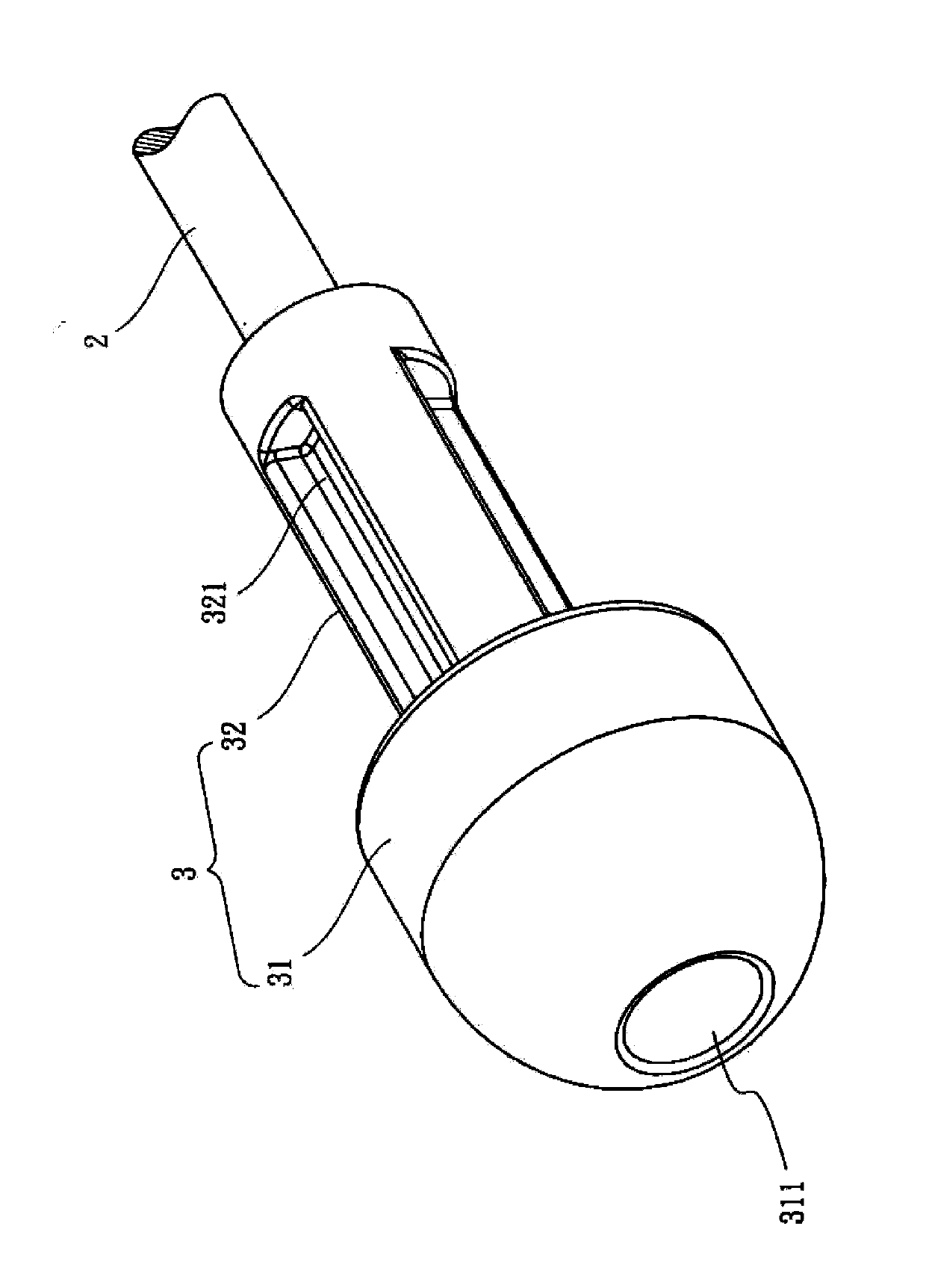

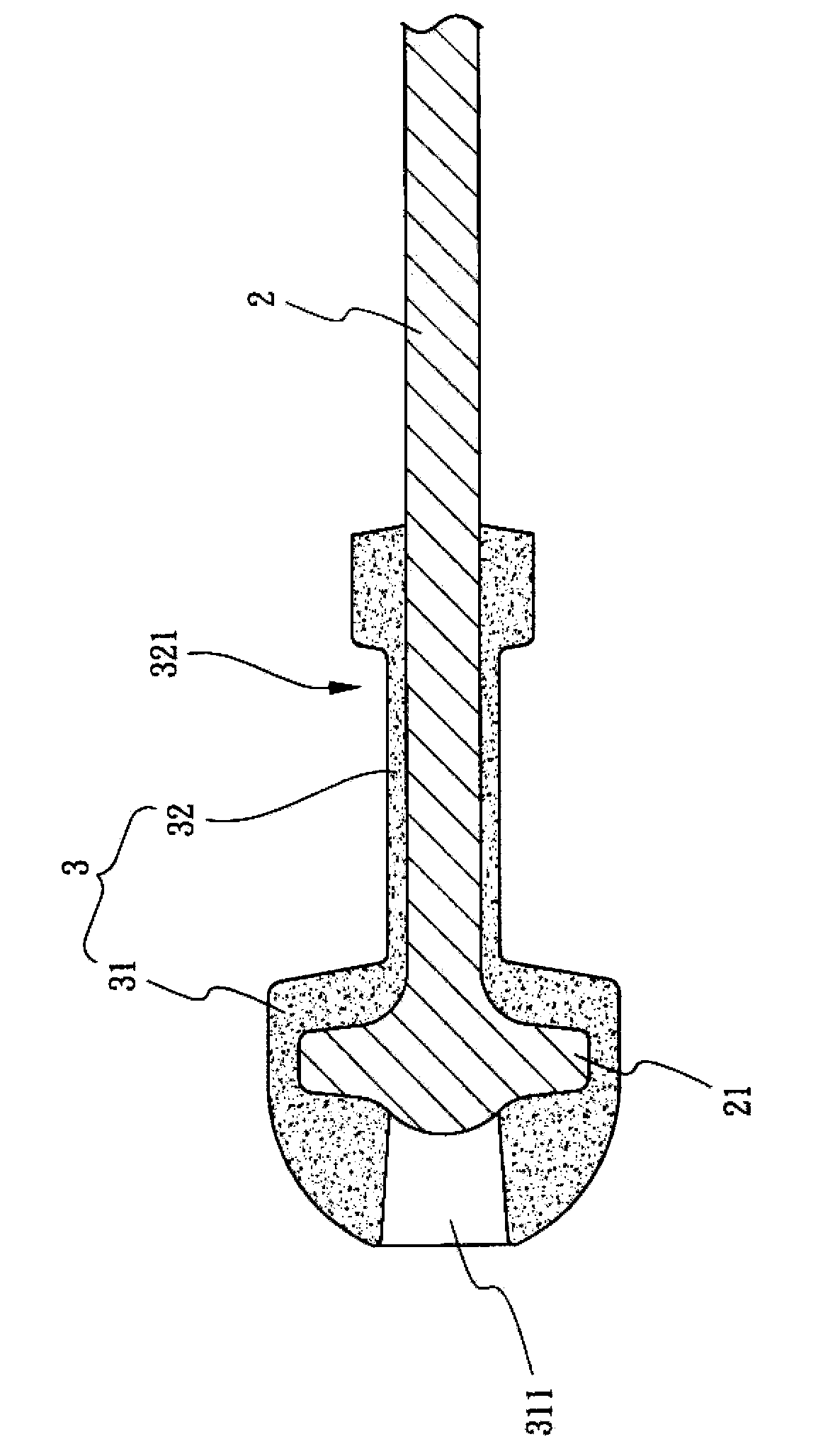

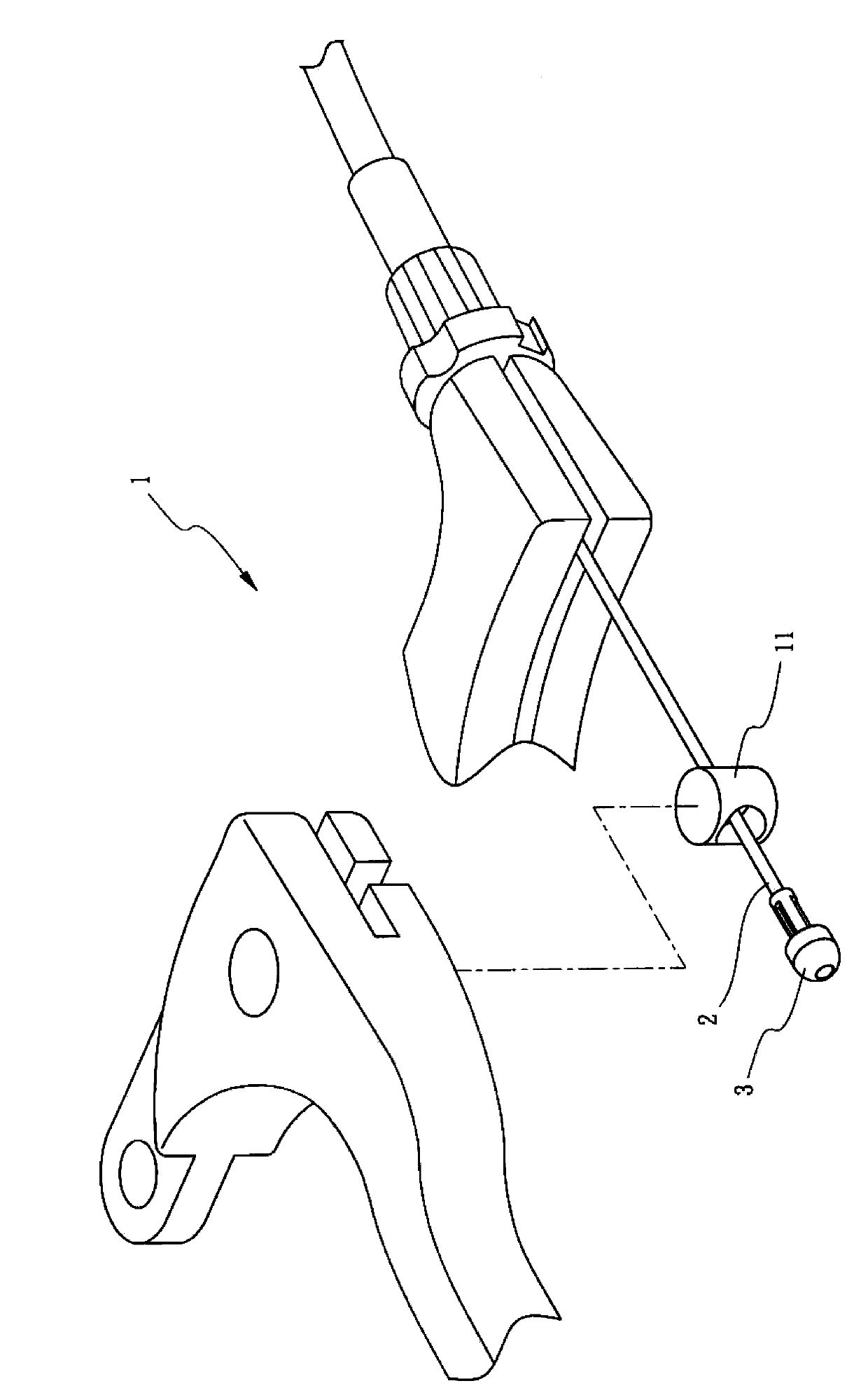

[0047] The following is an illustration of a preferred implementation mode, and does not limit the present invention in any form, see Figure 1 to Figure 3 As shown, wherein, the brake line end device of the present invention is assembled on the bicycle brake device 1, and is used to drive the brake device 1 to move, and it includes a core 2 and an ingot 3, wherein:

[0048] One end of the wire core 2 is provided with a knot 21, and the knot 21 is disc-shaped; the ingot 3 is wrapped around the end of the wire core 2 with the knot 21 and is conical, and the ingot 3 includes a A round head 31 and a body 32, the round head 31 is provided with a gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com