Method for employing in-situ fermentation technology to produce tuber mustard

A mustard, in-situ technology, applied in the field of mustard production using in-situ fermentation technology, can solve problems such as failure to meet standards and customer requirements, products that cannot achieve sterilization effects, and lack of market competitiveness for products. The amount of salt used, the effect of improving the nutritional value of products, and shortening the time of pickling and maturation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

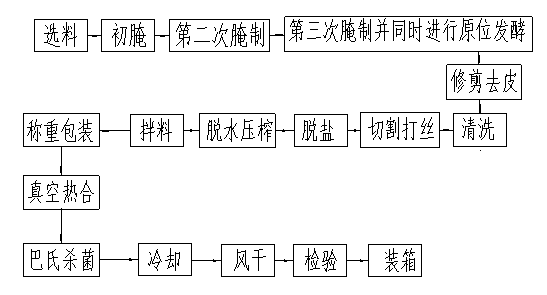

[0038] Embodiment 1: as figure 1 Shown, the method that adopts in-situ fermentation technology to produce mustard tuber comprises the following steps:

[0039] Step 1. Material selection: remove dark spots and rotten spots, spoons, candied vegetables, rotten vegetables, old vegetables, and fresh pickled vegetables after powder tips, and grade them according to size and weight. —0.15Kg, grade 3 ≤0.15Kg.

[0040] Step 2. Initial pickling: The process of initial pickling is to put into the pond, pave it flat, add salt, and seal the pond when it is full. According to the different grades, sprinkle salt in layers according to the thickness of 10-15CM, 15-20CM, and 20-25CM respectively, and control the amount of salt added according to the weight of fresh vegetables at about 3%-3.5%. The pond is sealed with food-grade thick plastic film. The bottom layer is laid on the bottom of the cellar, and then fresh mustard is loaded. A new layer of thick plastic film is covered on the ent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com