Electric supercharger using waste heat from internal combustion engine and power supply method thereof

An electric supercharging and internal combustion engine technology, which is applied in gas turbine devices, steam engine devices, internal combustion piston engines, etc., can solve the problems of slow engine response, severe electric charge and discharge, and driver's anxiety, reducing the number and setting. Quantity and cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

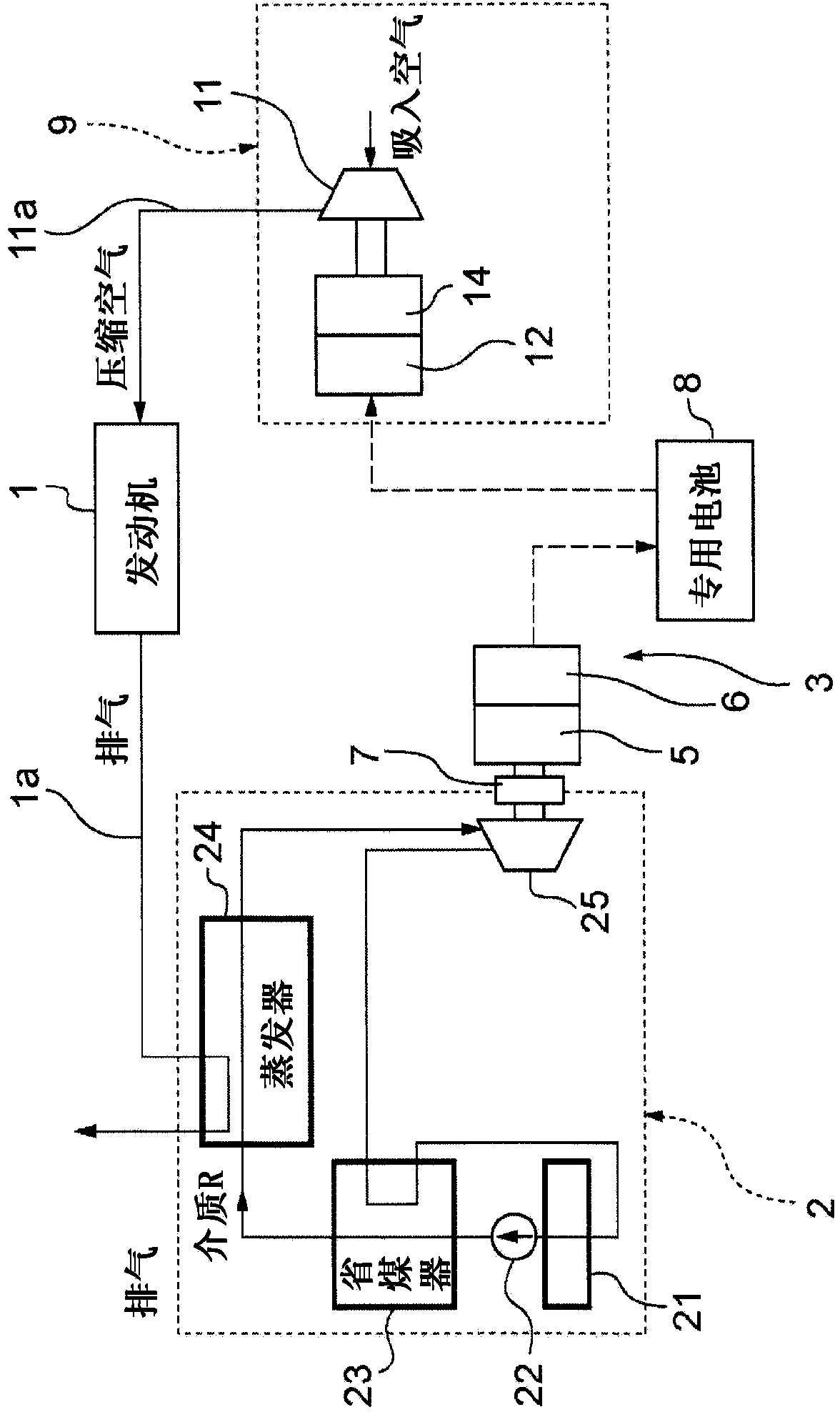

[0068] Shown is an overall schematic configuration diagram related to the electric supercharging device utilizing the waste heat of the engine according to the present invention, and 1 is an engine.

[0069] Exhaust gas discharged from the engine 1 is introduced into a steam cycle device 2 that converts heat of the exhaust gas into rotational energy through an exhaust pipe 1 a. The rotational energy of the steam cycle device 2 drives the first generator 5 via the magnetic coupling 7 as a non-contact joint to perform AC power generation. The alternating current is converted into direct current through the first converter 6 arranged in parallel with the first generator 5 (the first generator 5 and the first converter 6 constitute the first generating device 3 ), and is used as the first storage The battery 8 of the electric device stores electricity.

[0070] Reference numeral 9 denotes an electric supercharger, and the electric supercharger 9 is configured to drive the first c...

no. 2 approach

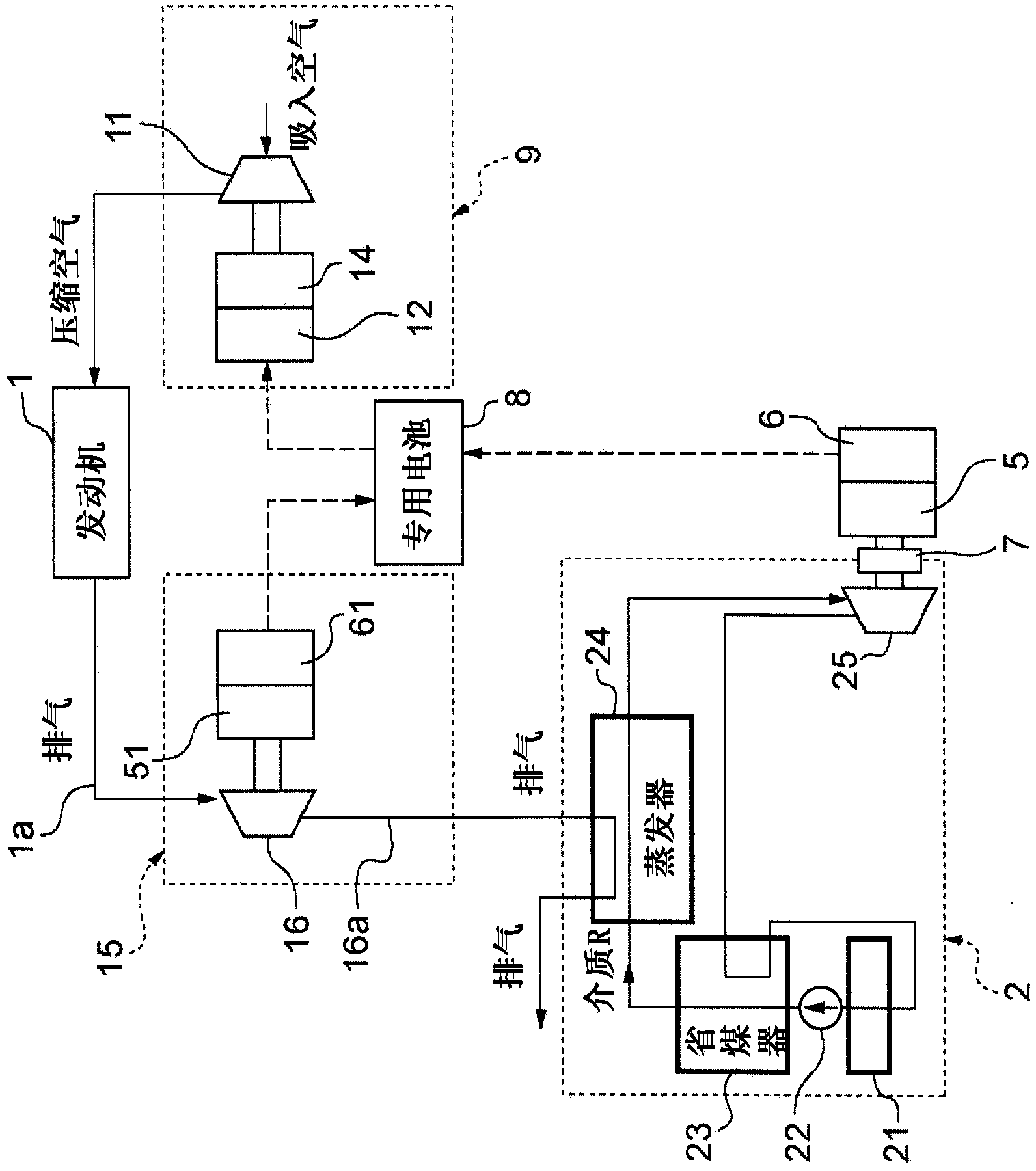

[0099] In this embodiment, the exhaust turbine generator 15 is installed between the steam cycle device 2 and the engine 1 compared to the first embodiment. Therefore, the same reference numerals are assigned to the same parts, and explanations thereof are omitted.

[0100] Exhaust gas discharged from the engine 1 is introduced into an exhaust turbine power generation device 15 as a second power generation device via an exhaust pipe 1 a. Exhaust gas from the exhaust turbine 16 that drives the exhaust turbine generator 15 is introduced into the steam cycle device 2 . The steam cycle device 2 rotationally drives an expander 25 serving as a steam turbine by steam of a liquid medium generated by the heat of the exhaust gas, and drives the first generator 5 to generate electricity. The generated electric current is converted from alternating current to direct current by the first converter 6 and charged to the battery 8 as a dedicated power storage device.

[0101] In addition, t...

no. 3 approach

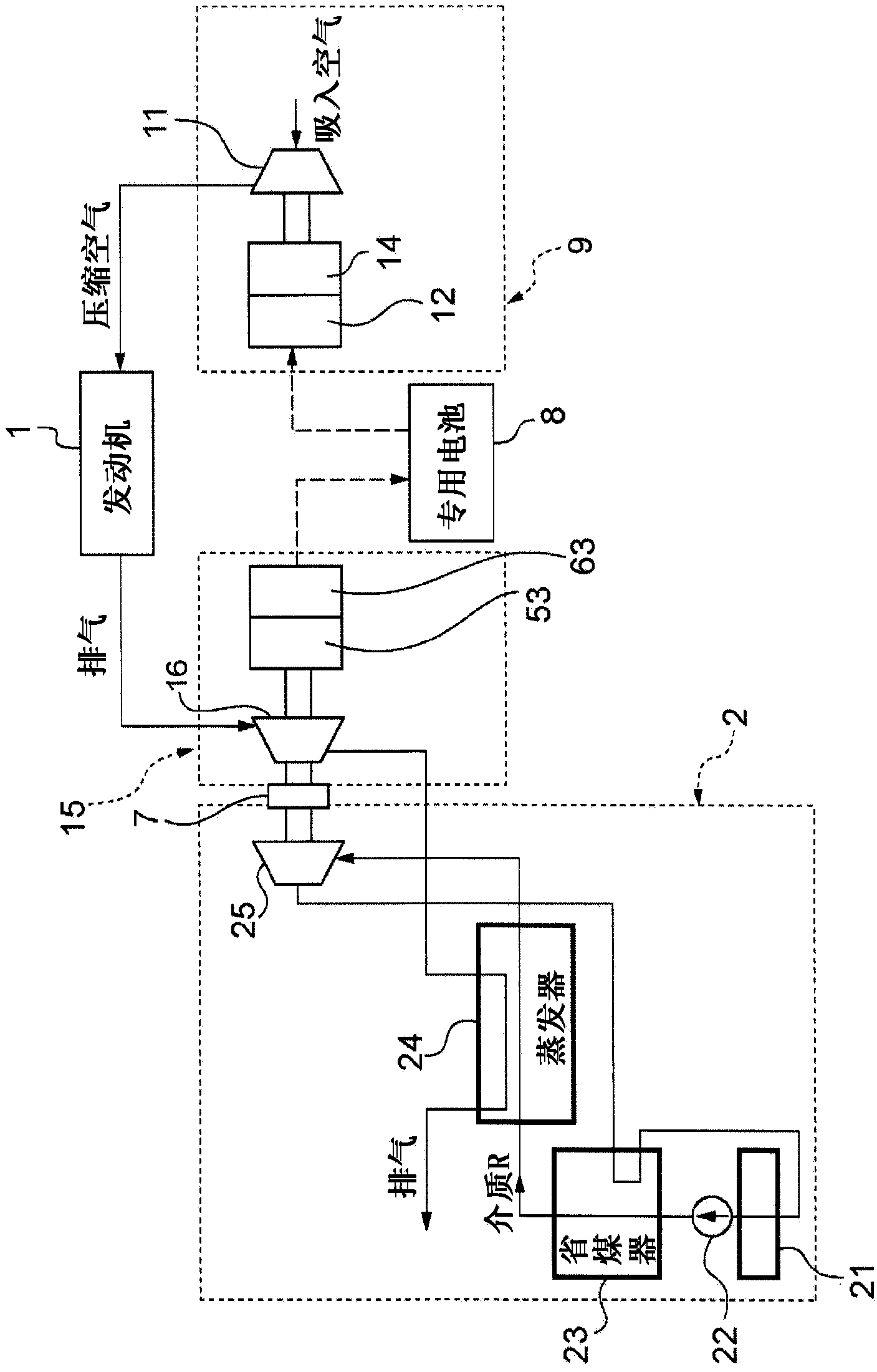

[0108] Compared with the first embodiment, this embodiment is a structure in which the rotation shaft of the expander 25 of the steam cycle device 2 and the rotation shaft of the exhaust turbine generator 15 of the second embodiment are coaxially connected by the magnetic coupling 7 .

[0109] Exhaust gas discharged from the engine 1 is introduced into the exhaust gas turbine generator 15 through the exhaust pipe 1 a. Exhaust gas from the exhaust turbine 16 that drives the exhaust turbine generator 15 is introduced into the steam cycle device 2 . The steam cycle device 2 changes the liquid medium into steam, and the expander 25 is rotationally driven by the steam.

[0110] The exhaust turbine power generation device 15 includes an exhaust turbine 16 rotationally driven by exhaust gas from the engine 1, a third generator 53 provided at the other end side of the rotation of the exhaust turbine 16, and the third generator 53 generating electricity. The current is converted from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com