High-speed cylindrical roller bearing and integrated monitoring device thereof

A technology of cylindrical roller bearing and monitoring device, which is applied in bearing assembly, mechanical bearing testing, shaft and bearing, etc., can solve the problems of piezoelectric vibrator difficult to obtain kinetic energy, short overlapping time, and vibration, etc., and achieves novel structure and increased The effect of kinetic energy, power generation, and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

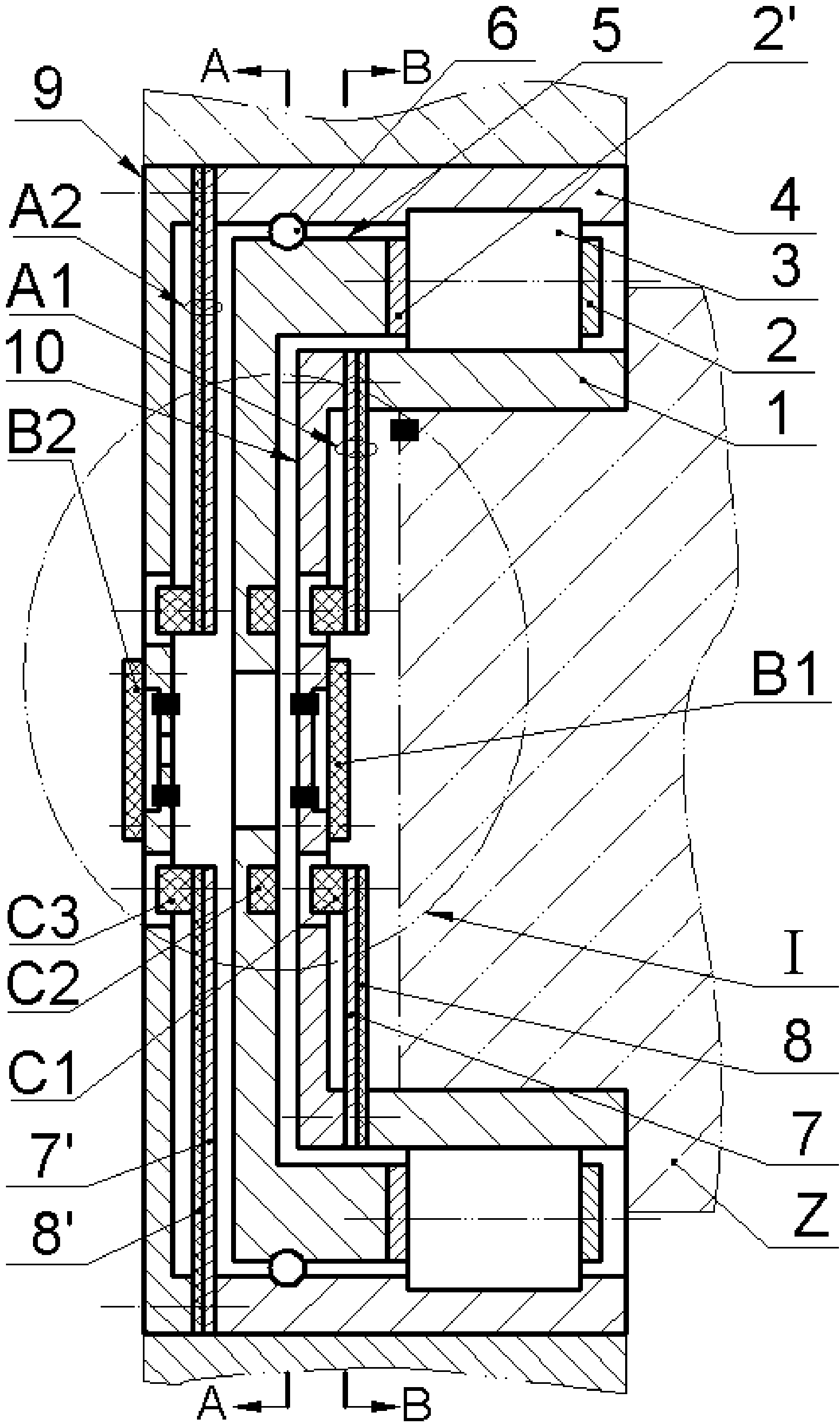

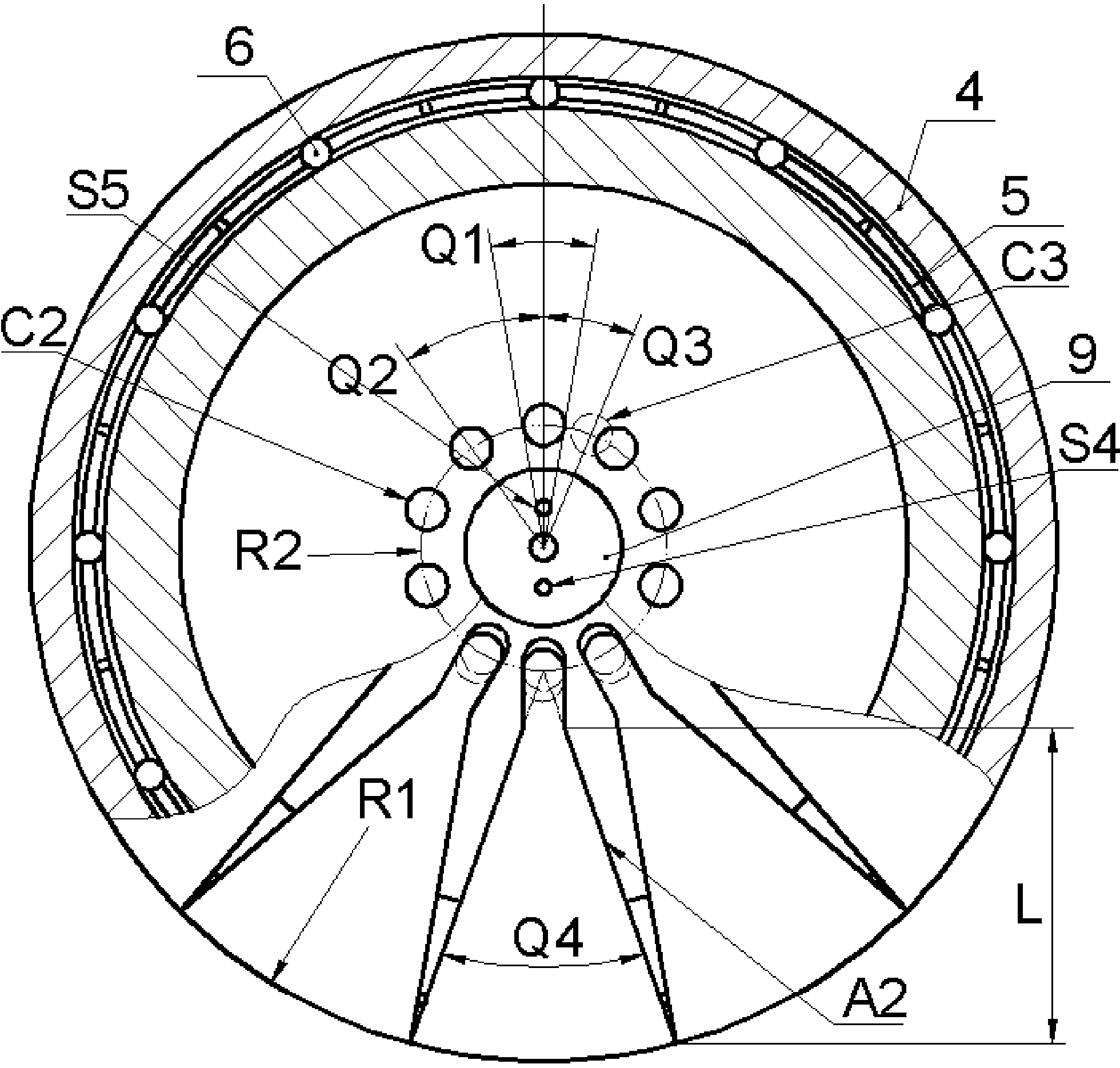

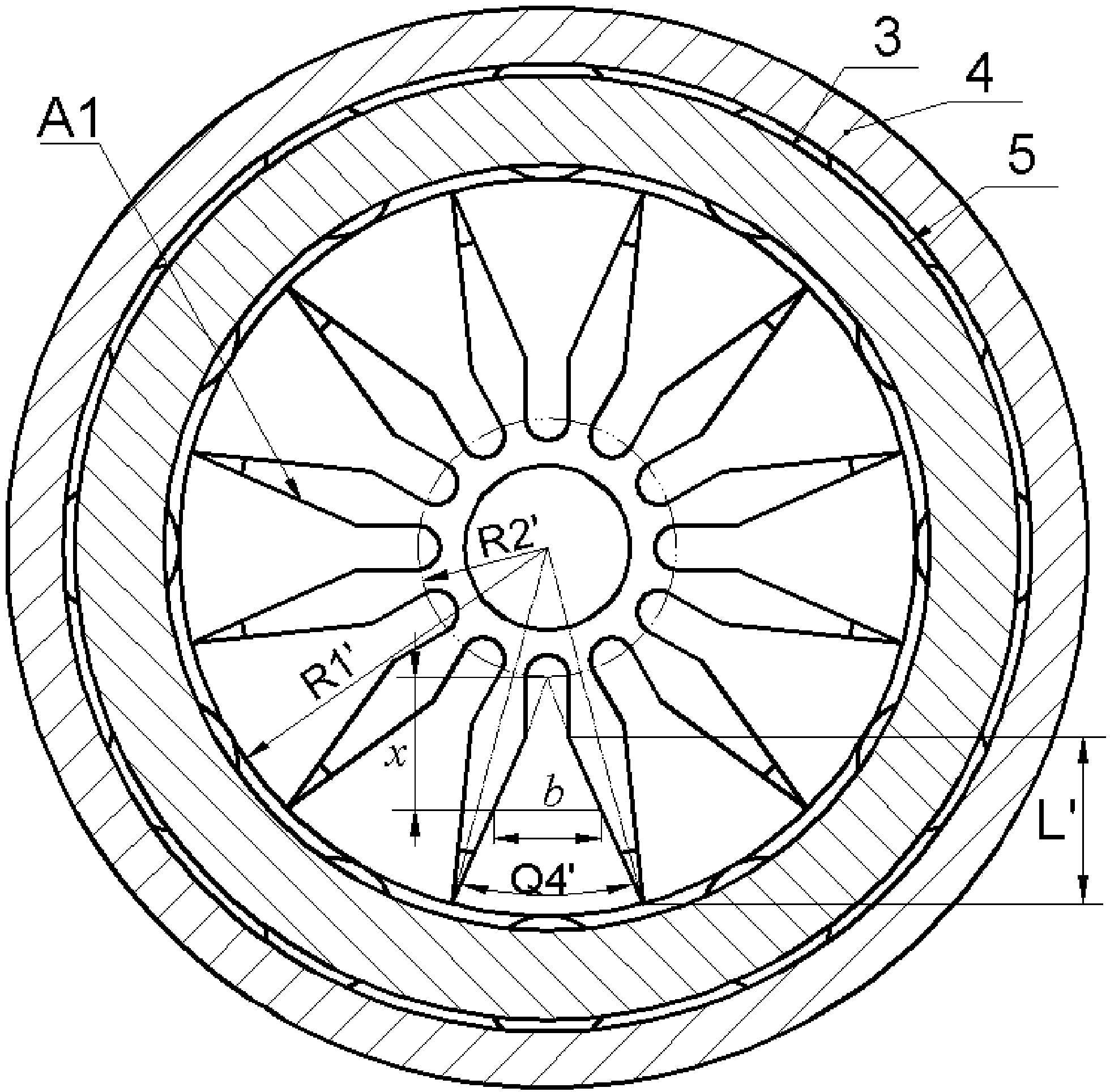

[0017] like Figure 1 to Figure 7 As shown, the present invention includes: an inner ring 1, a cage 21 and a cage two 2', a cylinder 3 for bearing bearing, an outer ring 4, an excitation disc 5, a ball 6 for positioning the excitation disc 5, and a fixed Disk 9, moving disk 10, cantilever beam piezoelectric vibrator 1 A1 and cantilever beam piezoelectric vibrator 2 A2, magnet 1 C1, magnet 2 C2 and magnet 3 C3, circuit board 1 B1 and circuit board 2 B2, temperature sensor S1, internal Ring vibration sensor S2, noise sensor S3, outer ring vibration sensor S4, speed sensor S5, and wires.

[0018] The inner ring 1 is narrower than the outer ring 4, and one side of the inner ring 1 and the outer ring 4 are aligned and installed, and the end face of the inner ring 1 on the non-aligned side is fixed with a moving disc 10 by screws, and the flange 101 of the end face of the moving disc 10 is aligned with the inner ring 1. A cantilever beam-type piezoelectric vibrator-A1 bonded by a m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com