High-intensity discharge lamp

A technology for high-intensity discharge lamps and discharge capacitors, which is applied to high-pressure discharge lamps, discharge lamps, and gas discharge lamps. It can solve problems such as the influence and disadvantage of light radiation characteristics, and achieve the effects of improving efficiency and reducing thermal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

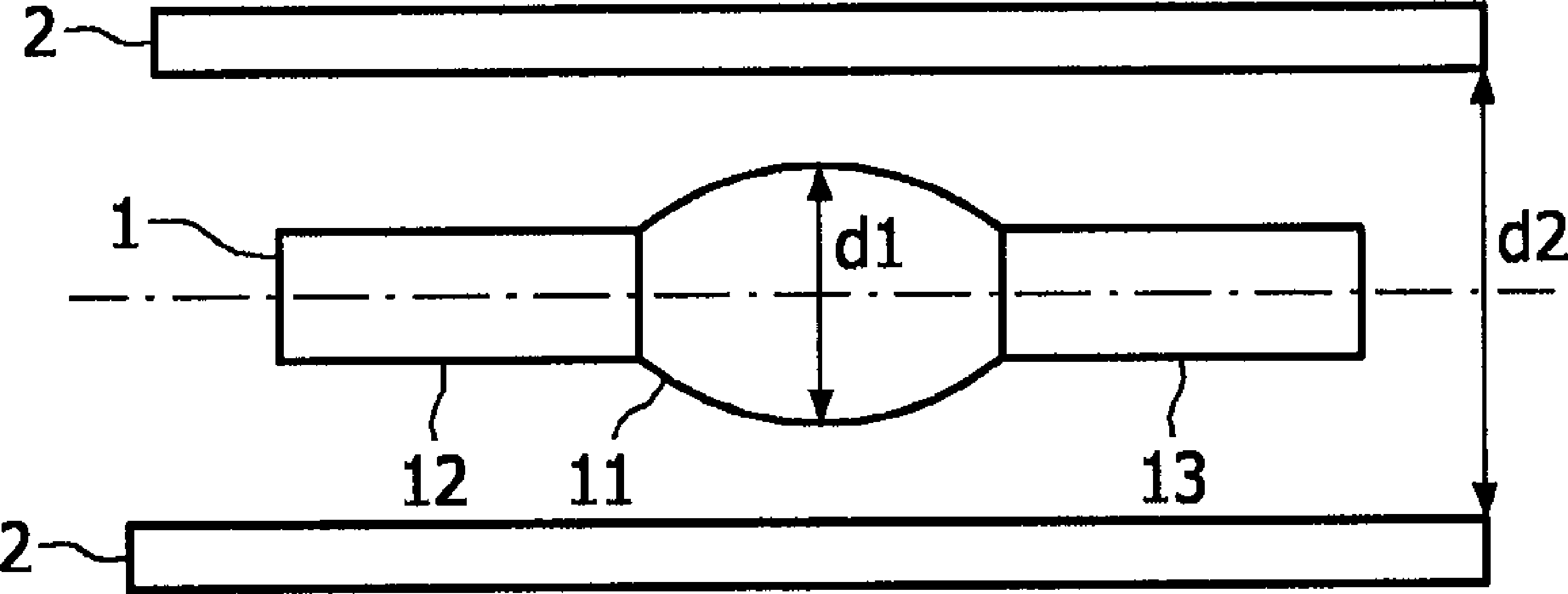

[0030] figure 1 A typical construction of a high-intensity discharge lamp is shown in longitudinal section, which involves the above-mentioned problems during start-up and steady-state operation. The lamp is provided for horizontal operation and comprises an inner tube or bulb 1 and an outer tube or bulb or lamp vessel 2 (only a part of which is shown) surrounding the inner bulb 1 .

[0031] The inner bulb 1 comprises a first central part or discharge vessel 11 having a first diameter d1 for enclosing the discharge volume. At axially opposite ends of the discharge vessel 11 there are provided a first elongated constriction 12 and a second elongate constriction 13 for enclosing electrical contacts for electrodes (not shown) extending into the discharge vessel 11 And a gas discharge is excited between the electrodes. The inner bulb 1 is enclosed by a substantially cylindrical outer bulb 2 having a second diameter d2.

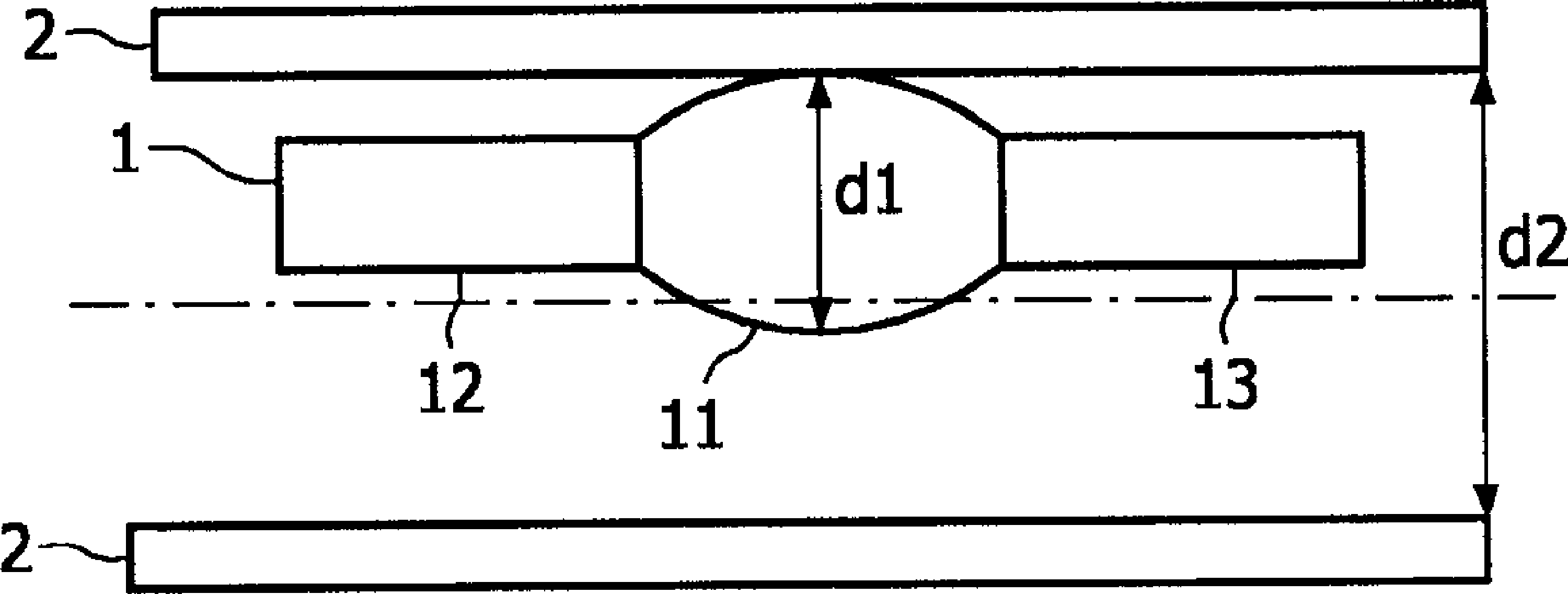

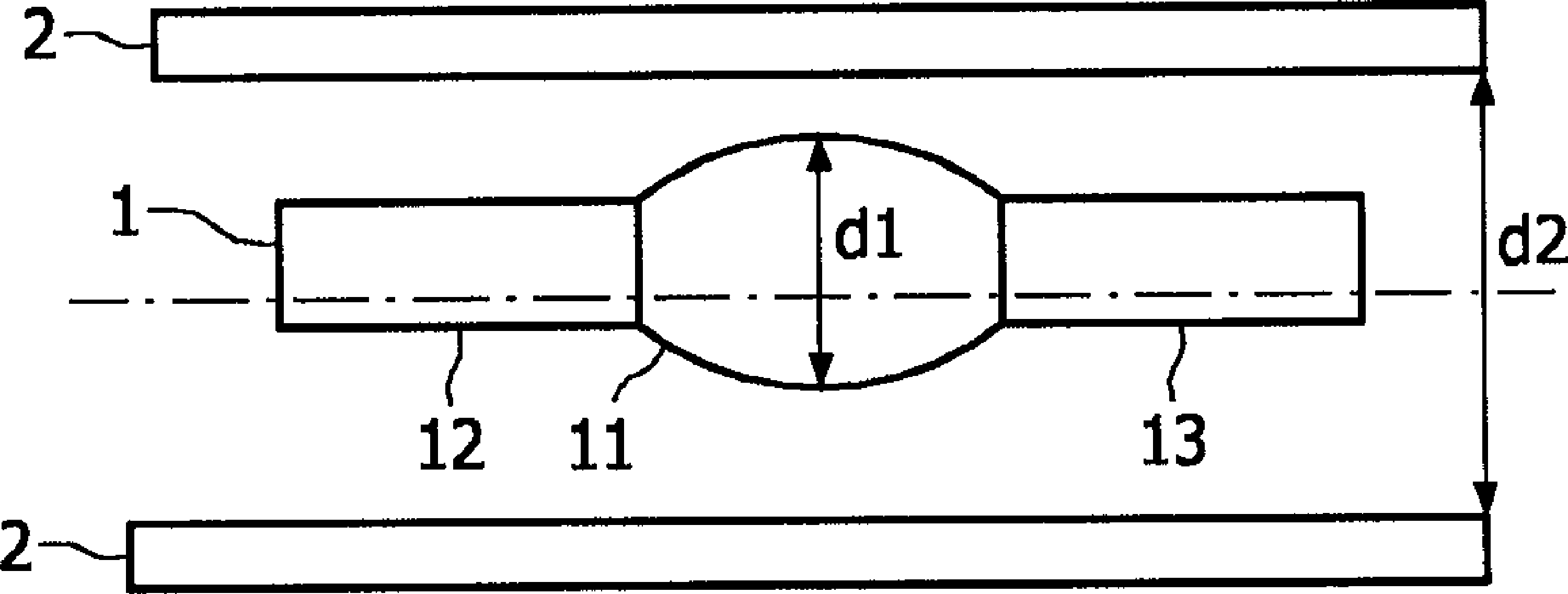

[0032] According to figure 2 In the first embodiment of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com