Infrared metamaterial wave absorbing body

A technology of wave absorber and infrared ultra-high, applied in the infrared field, can solve the problems of narrow tunable range, limit the wide application of infrared metamaterial wave absorbers, and reduce the absorption rate, and achieve the effect of ultra-high absorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

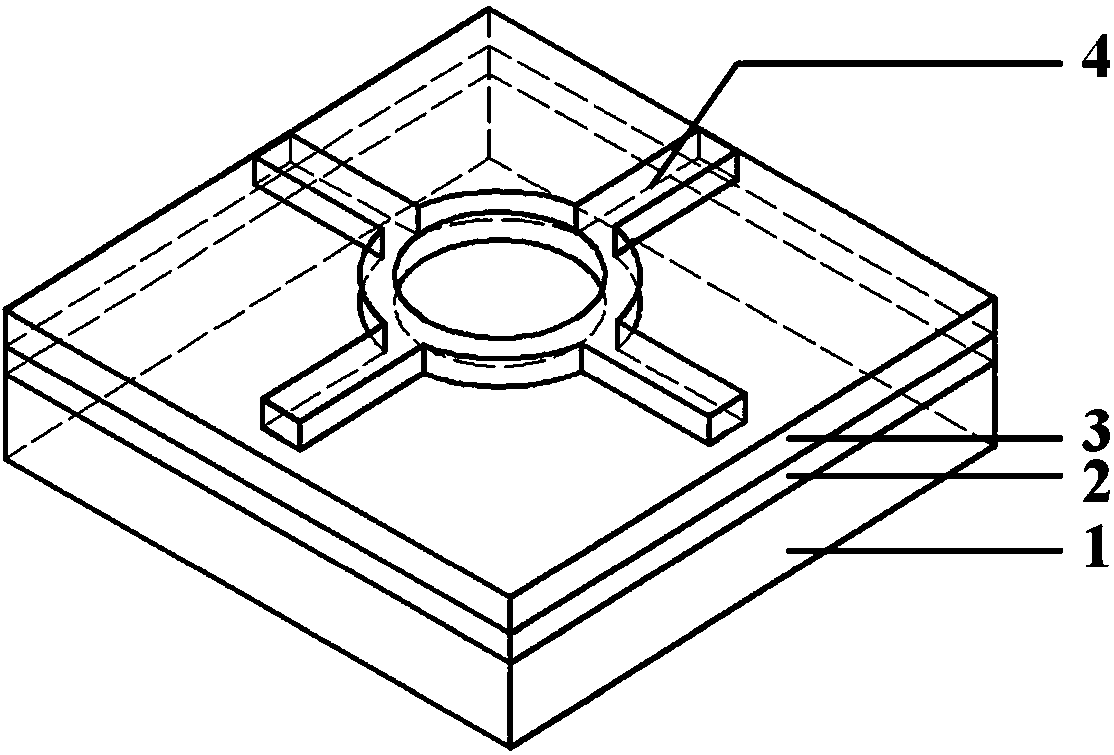

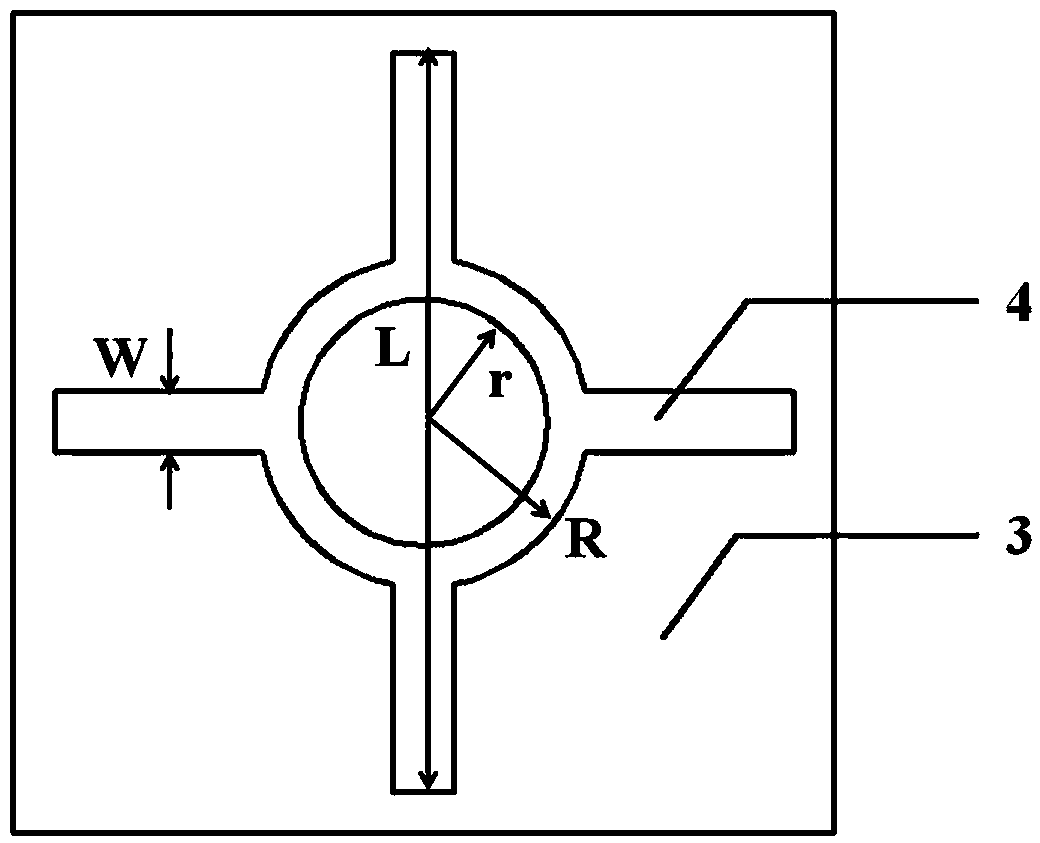

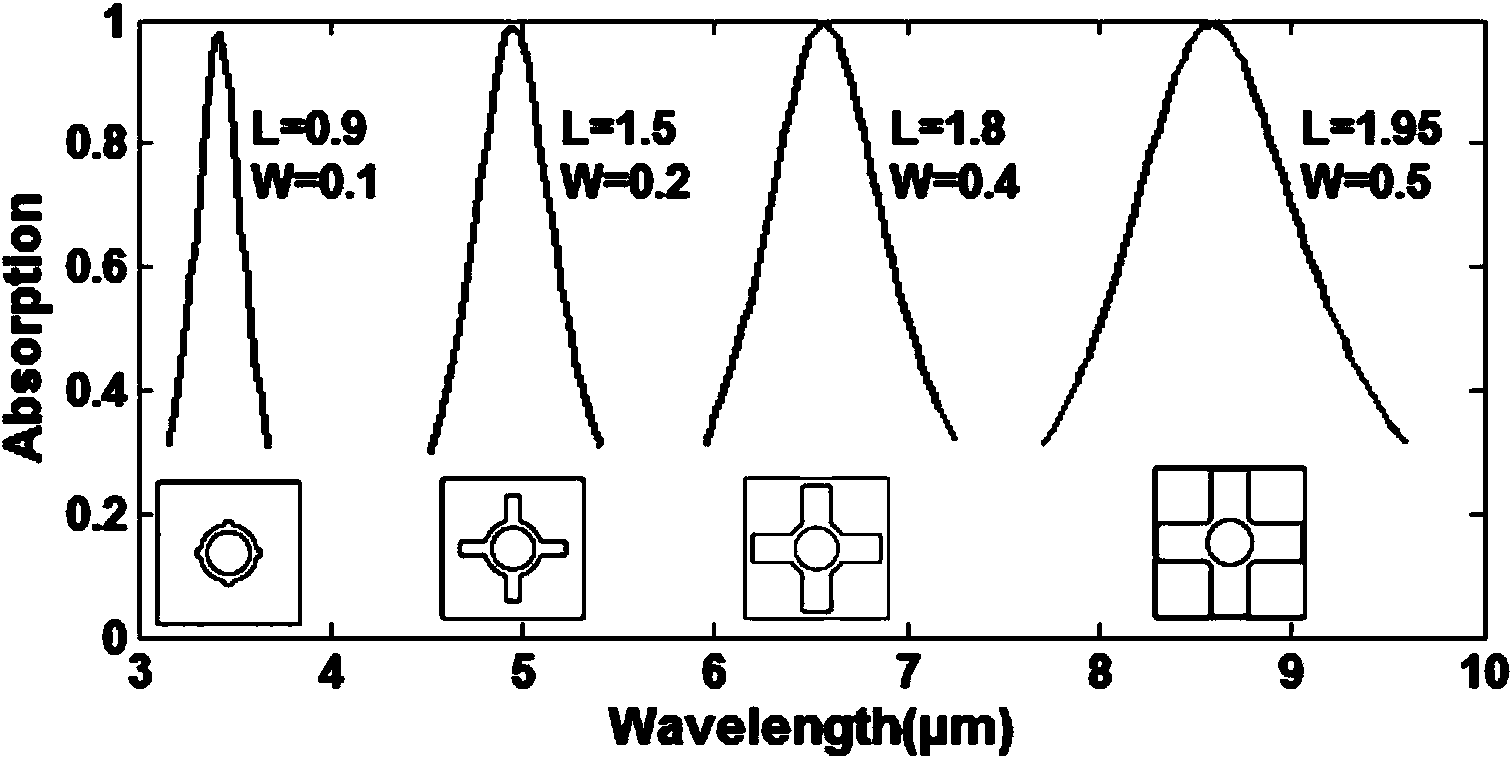

[0024] An infrared metamaterial absorber, the absorber uses four absorber units to form a 2×2 two-dimensional array structure, wherein each absorber unit includes a substrate 1, a metal layer 2, a dielectric layer 3 and a cross circle Ring structure 4. The upper and lower surfaces of the metal layer 2 are in contact with the lower surface of the dielectric layer 3 and the upper surface of the substrate 1 respectively. The substrate 1 is made of silicon material with a thickness of 50 microns; the metal layer 2 is located directly above the substrate 1 and is a continuous layer. The metal film is made of gold with a thickness of 0.1 micron; the dielectric layer 3 is located directly above the metal layer 2 and is made of magnesium fluoride with a thickness of 0.13 micron; the cross ring structure 4 is located directly above the dielectric layer 3 and is formed by A ring and a cross are intersected, and the cross part inside the ring is removed. The center of the ring coincides ...

Embodiment 2

[0026] An infrared metamaterial absorber, the absorber uses four absorber units to form a 2×2 two-dimensional array structure, wherein each absorber unit includes a substrate 1, a metal layer 2, a dielectric layer 3 and a cross circle Ring structure 4. The upper and lower surfaces of the metal layer 2 are in contact with the lower surface of the dielectric layer 3 and the upper surface of the substrate 1 respectively. The substrate 1 is made of silicon material with a thickness of 50 microns; the metal layer 2 is located directly above the substrate 1 and is a continuous layer. The metal film is made of gold with a thickness of 0.1 micron; the dielectric layer 3 is located directly above the metal layer 2 and is made of magnesium fluoride with a thickness of 0.13 micron; the cross ring structure 4 is located directly above the dielectric layer 3 and is formed by A ring and a cross are intersected, and the cross part inside the ring is removed. The center of the ring coincides ...

Embodiment 3

[0028] An infrared metamaterial absorber, the absorber uses four absorber units to form a 2×2 two-dimensional array structure, wherein each absorber unit includes a substrate 1, a metal layer 2, a dielectric layer 3 and a cross circle Ring structure 4. The upper and lower surfaces of the metal layer 2 are in contact with the lower surface of the dielectric layer 3 and the upper surface of the substrate 1 respectively. The substrate 1 is made of silicon material with a thickness of 50 microns; the metal layer 2 is located directly above the substrate 1 and is a continuous layer. The metal film is made of gold with a thickness of 0.1 micron; the dielectric layer 3 is located directly above the metal layer 2 and is made of magnesium fluoride with a thickness of 0.13 micron; the cross ring structure 4 is located directly above the dielectric layer 3 and is formed by A ring and a cross are intersected, and the cross part inside the ring is removed. The center of the ring coincides ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Inner radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com