Visual concrete-structured reinforcing steel corrosion test device and operation method of visual concrete-structured reinforcing steel corrosion test device

A concrete structure and steel bar corrosion technology, which is applied in measuring devices, weather resistance/light resistance/corrosion resistance, instruments, etc., can solve problems such as poor visibility, heavy workload, and affecting the objectivity and accuracy of the test, so as to improve the space Utilization rate, increased zigzag length, and the effect of overcoming poor visibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

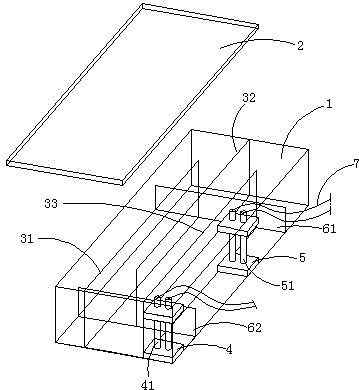

[0024] like Figure 1 to Figure 2 Shown is the structural representation of the present invention,

[0025] The reference signs therein are: test box 1, case cover 2, first deflector 31, second deflector 32, third deflector 33, reference electrode holder 4, reference electrode 41, test piece Fixing seat 5, test piece 51, upper deflector fixed plate 61, lower deflector fixed plate 62, monitoring connecting wire 7.

[0026] like Figure 1 to Figure 2 as shown,

[0027] A test device for steel bar corrosion in concrete structures, comprising a test box 1 and a box cover 2 capable of sealingly covering the test box 1, wherein the test box 1 and the box cover 2 are both made of transparent materials, and the test box 1 is provided with a transparent Deflectors and transparent deflectors are arranged alternately to divide the inner space of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com