Horizontal test device for reliability test of aircraft landing gear door up lock

A technology of aircraft landing gear and test equipment, which is applied in the direction of measuring equipment, testing of mechanical components, testing of machine/structural components, etc. It can solve the problems that the test requirements cannot meet the requirements, do not have driving components, and cannot be triggered. Lightweight, small additional resistance, and compact loading structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described below in conjunction with specific embodiments:

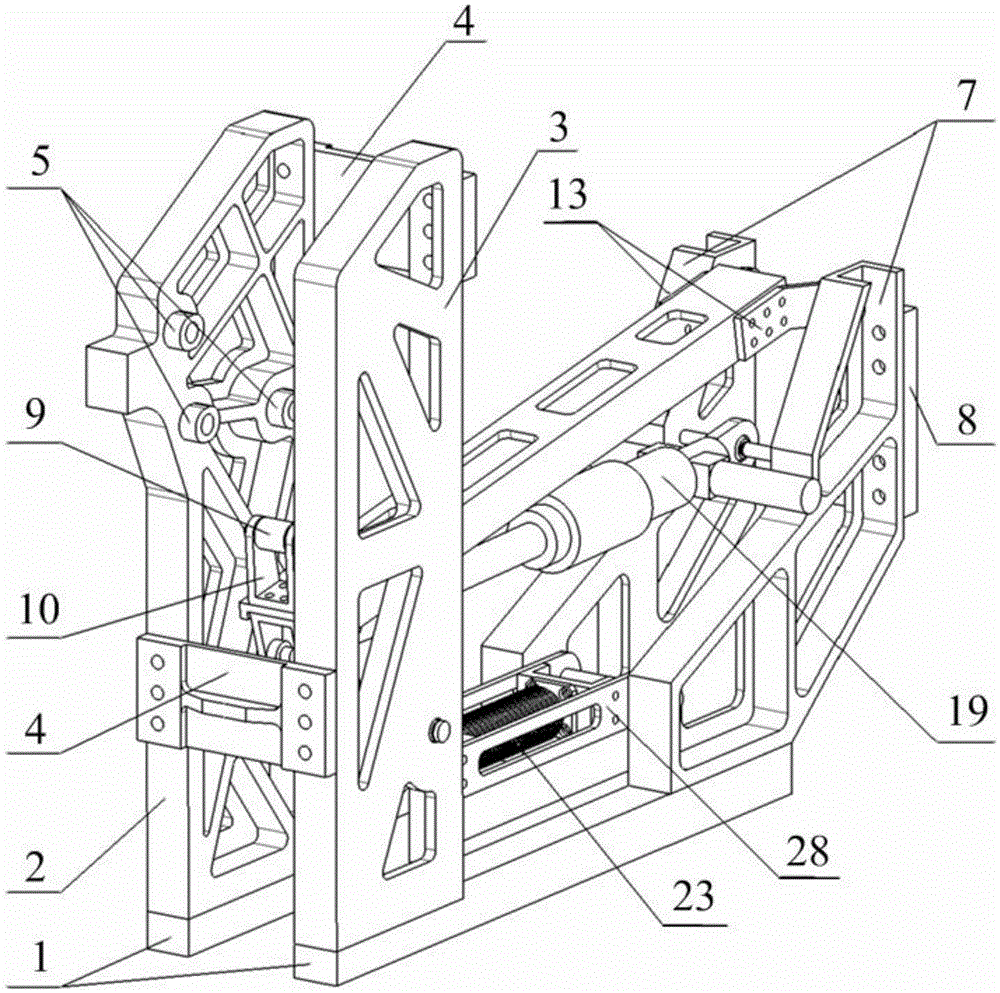

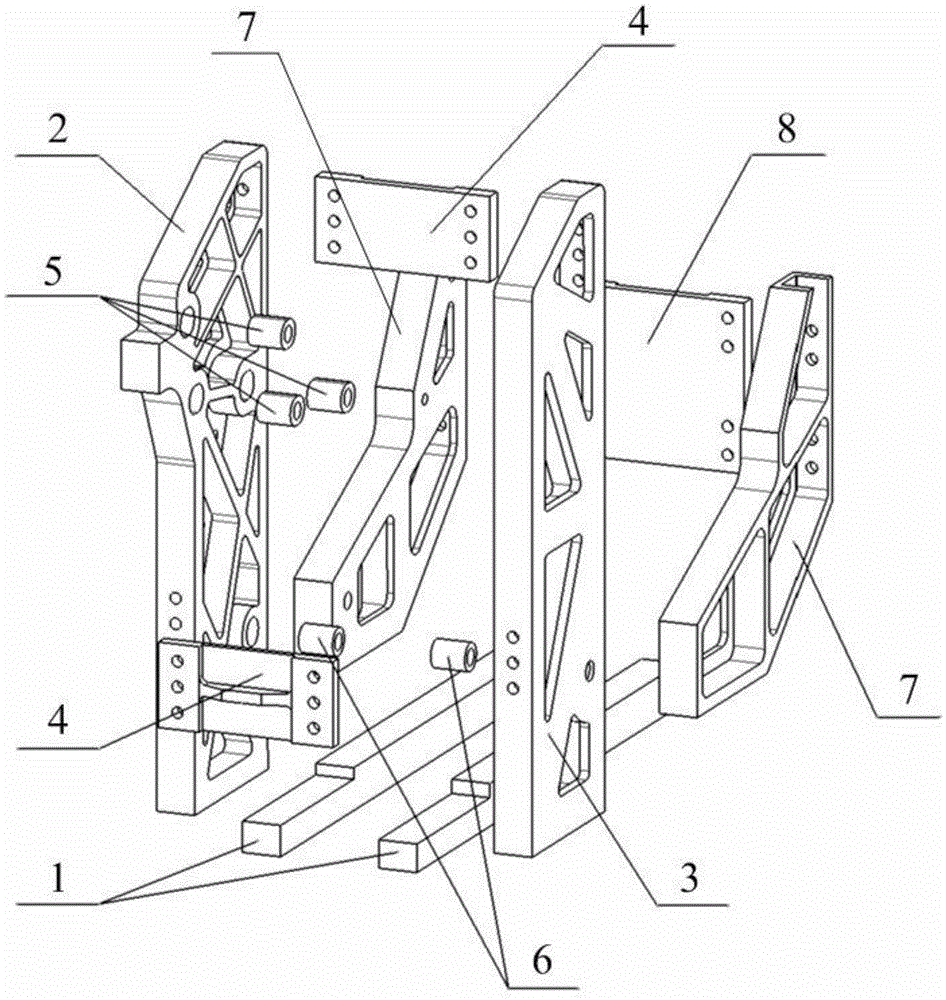

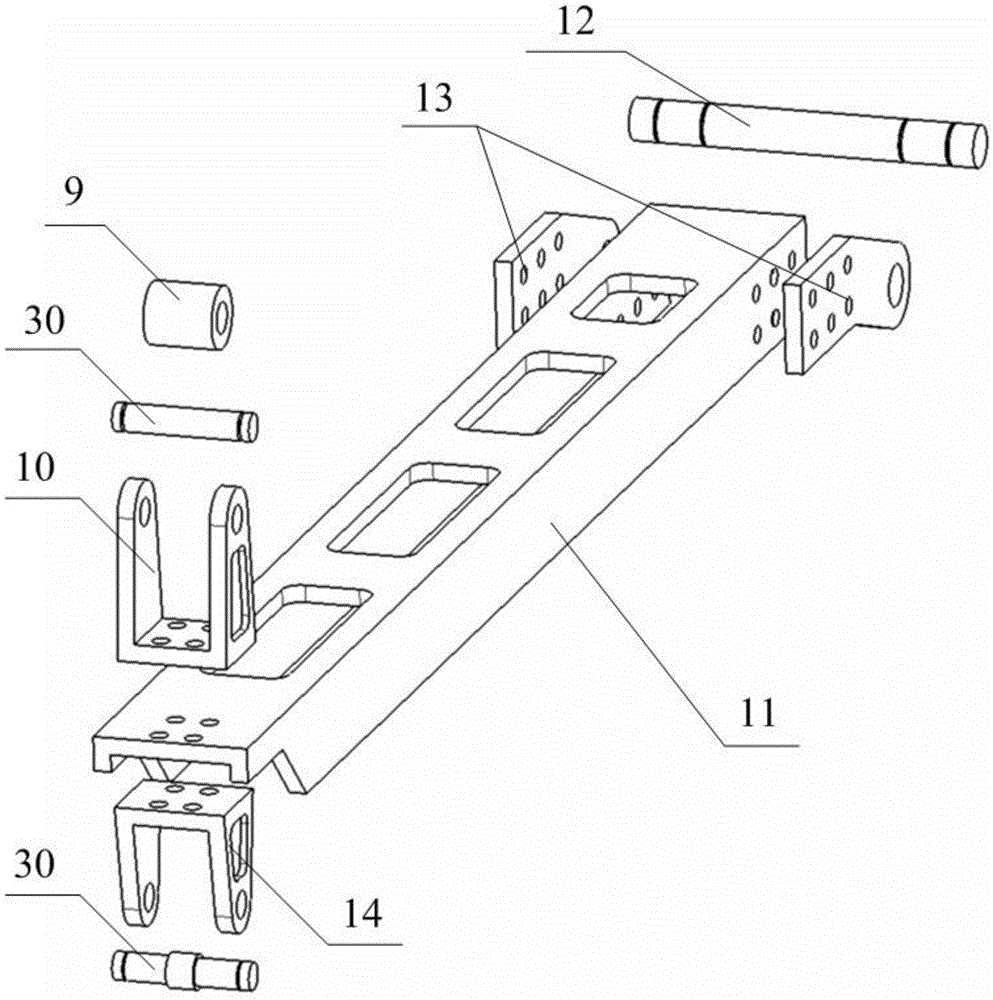

[0028] The horizontal test device used for the reliability test of the upper lock of the aircraft landing gear door in this embodiment is composed of a connecting support structure, a simulated door structure, and a driving loading structure.

[0029] The upper lock of the cabin door to be tested, the simulated cabin door structure and the drive loading structure are all installed on the connecting support structure, and the connecting support structure is also the connection interface with the external vibration test bench. The installation method of the upper lock of the cabin door to be tested is consistent with the real situation. The simulated cabin door structure is used to simulate the movement trajectory of the cabin door lock ring so that the movement trajectory of the lock ring in the test device is consistent with the movement trajectory of the lock ring required by the test ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com