A brake friction, heating, vibration coupling test bench

A technology of brakes and test benches, which is applied in the fields of vibration coupling test benches, brake friction, and heat generation. It can solve the problems of lack of brakes, etc., and achieve the effects of convenient and accurate setting, easy measurement and control, and high guiding value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to further explain the technical solution of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings.

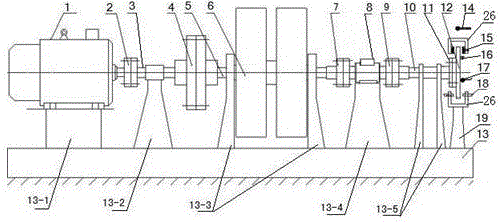

[0016] like figure 1 and figure 2 As shown, the brake friction, heating, and vibration coupling test bench includes a base 13, on which a first support 13-1, a second support 13-2, and a third support 13-3 are sequentially arranged from left to right , the fourth bracket 13-4, the fifth bracket 13-5 and the brake caliper assembly mounting bracket 19;

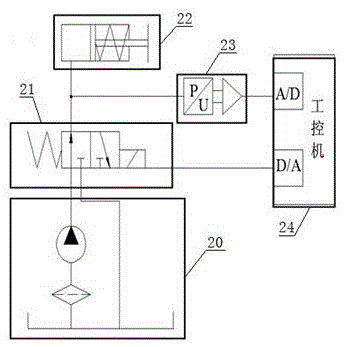

[0017] Each part of a power drive device is respectively arranged on the first support 13-1, the second support 13-2, the third support 13-3, the fourth support 13-4 and the fifth support 13-5, a braking device The brake 22 is located on the brake caliper assembly mounting bracket 19, and the output end of the power drive device is connected to the input end of the brake device;

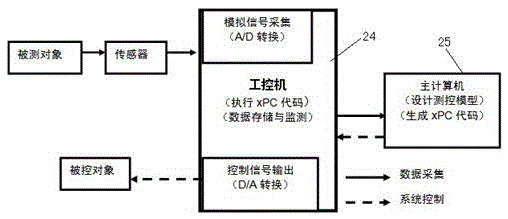

[0018] The sensor elements of a collection and measurement ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com