Fast feeding and blanking equipment for multi-layer box type heating furnace

A heating furnace, fast technology, applied in the field of loading and unloading equipment of multi-layer atmosphere protection box furnace, fast loading and unloading industrial equipment, can solve the problem of small thickness of sheet metal, reduce the difficulty of installation, realize rapid acceleration and deceleration up and down movement, The effect of reducing the overall weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following describes the rapid loading and unloading equipment for a multi-layer box-type heating furnace according to an embodiment of the present invention with reference to the accompanying drawings.

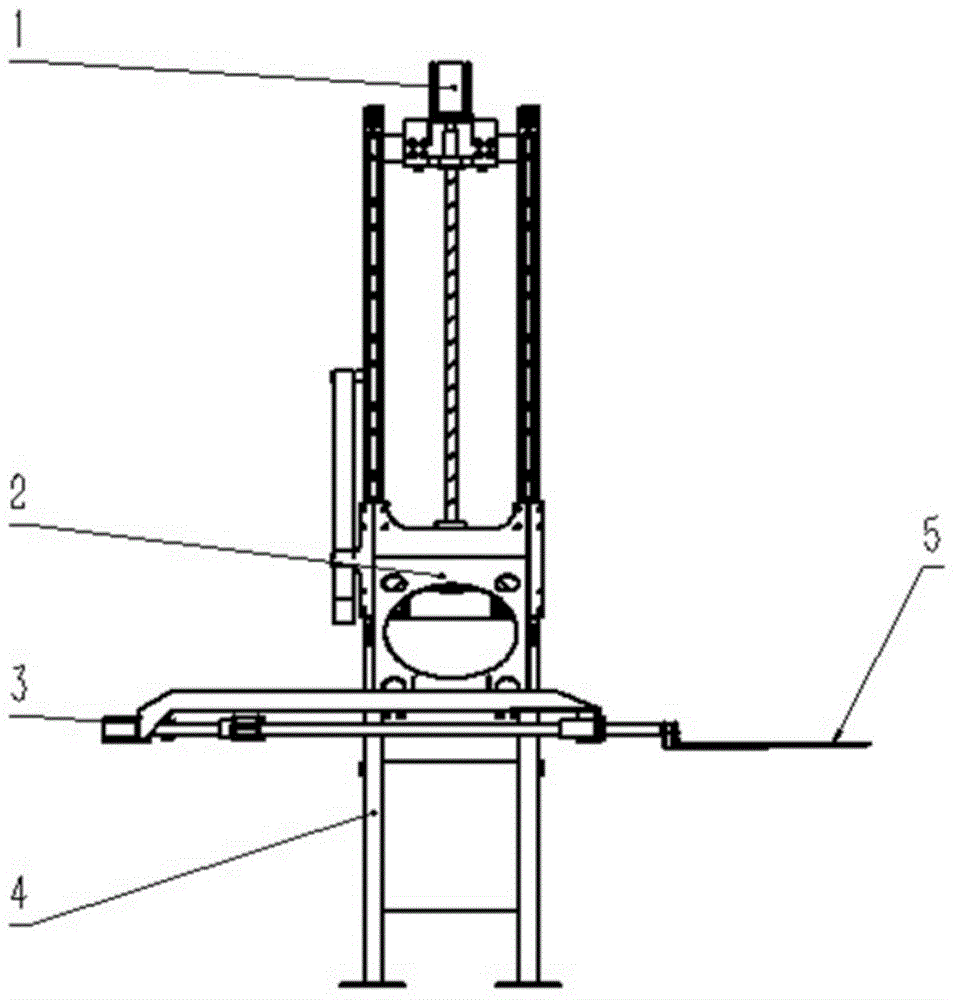

[0026] figure 1 It is a structural schematic diagram of a fast loading and unloading industrial robot for a multi-layer box-type heating furnace according to an embodiment of the present invention.

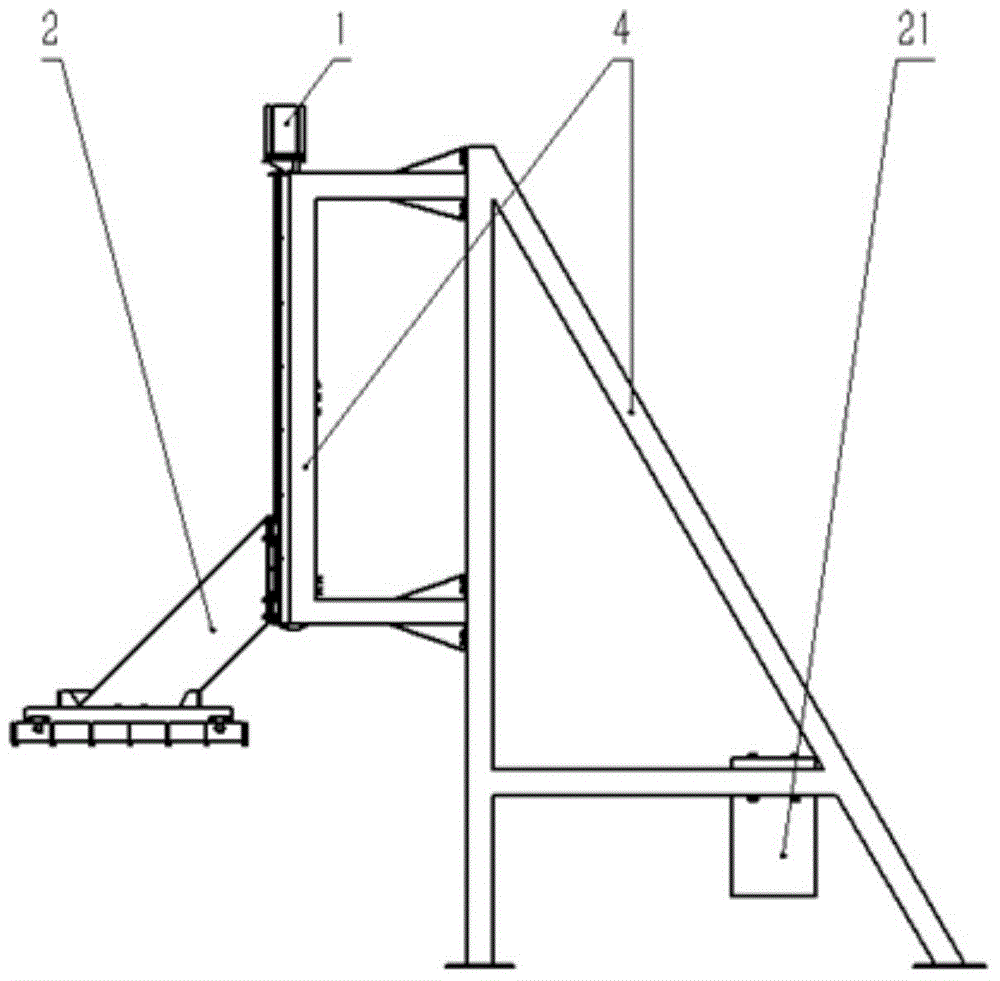

[0027] Such as figure 1 , figure 2 As shown, the fast loading and unloading industrial robot used in the multi-layer box-type heating furnace in this embodiment includes a main support frame 4, a counterweight 21, a Z-axis up and down movement mechanism, a main slider body 2, an X-axis movement mechanism, Interchangeable finger manipulator 5, Z-axis motor 1, X-axis motor 3.

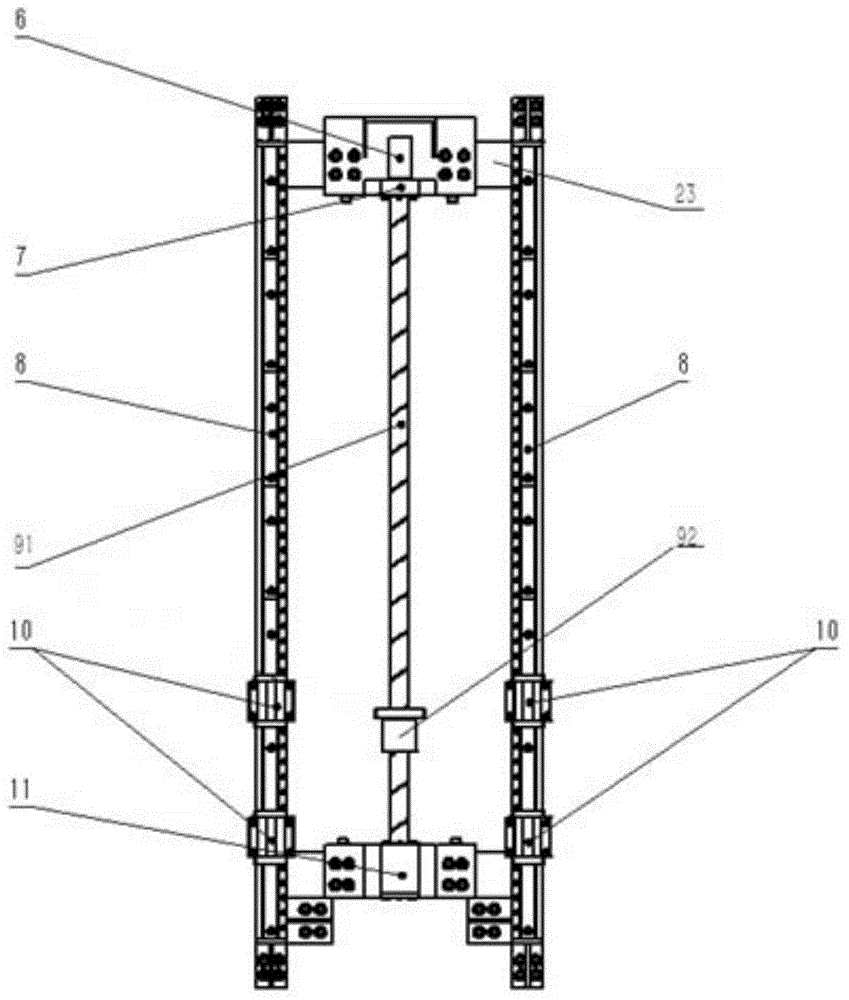

[0028] The Z-axis up and down movement mechanism is vertically arranged and fixed on the main support frame 4. The Z-axis motor 1 drives the ball screw group 9 in the Z-axis up and down movemen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com