Feedforward Dynamic Spool Valve

A sliding valve, actuation technology, applied to non-mechanically actuated valves, valve devices, engine components, etc., can solve problems such as engine parts degradation and engine knocking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

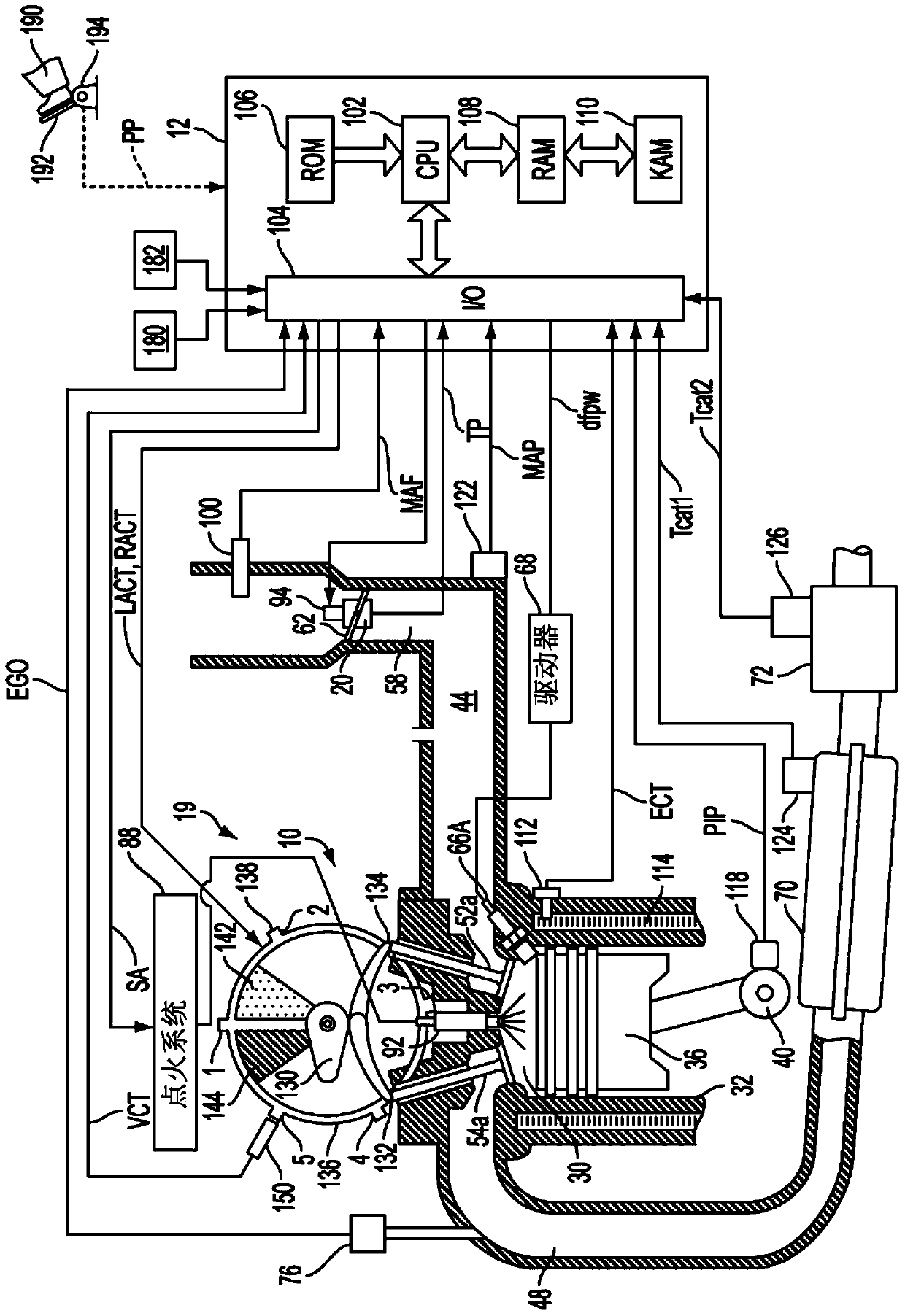

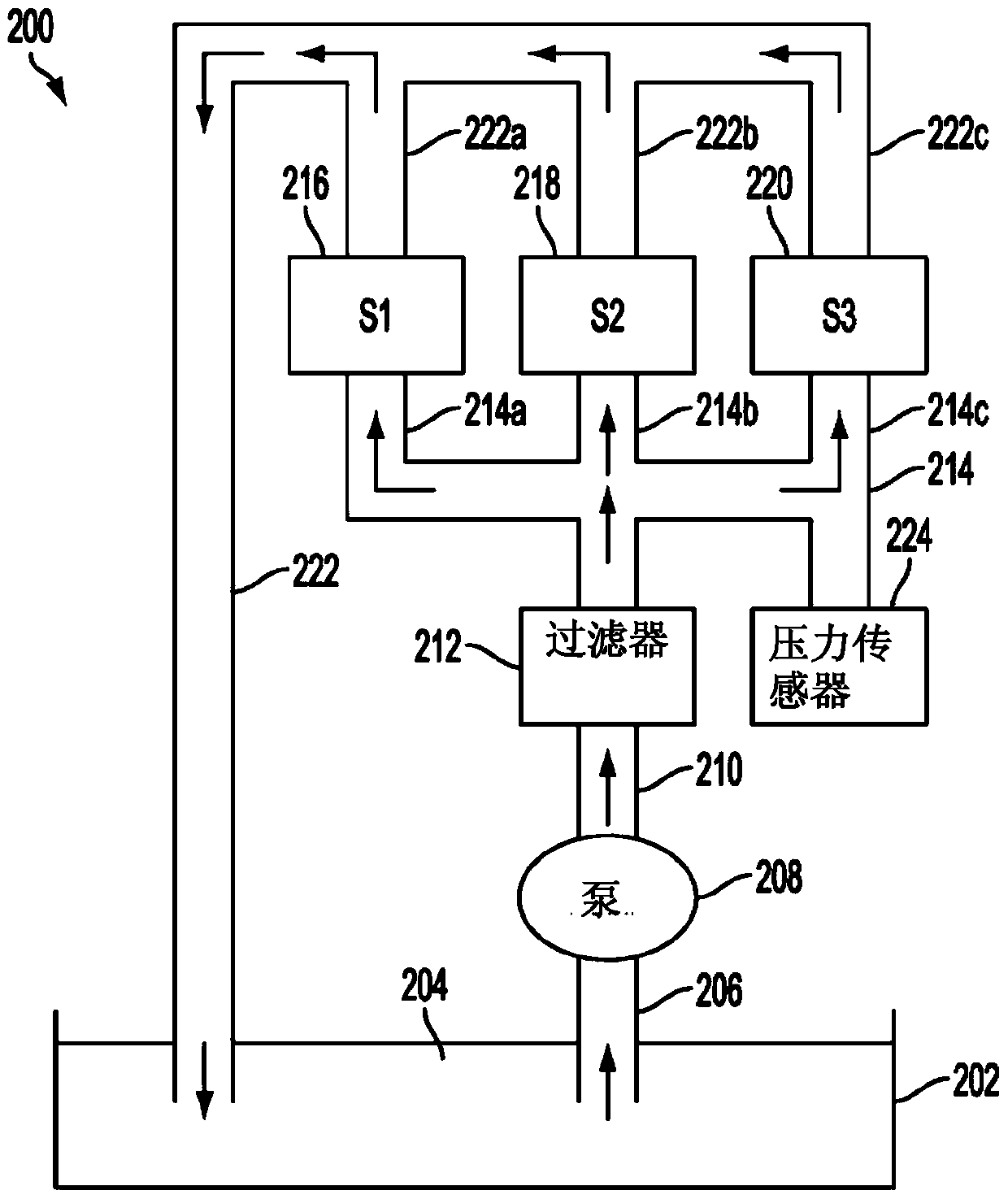

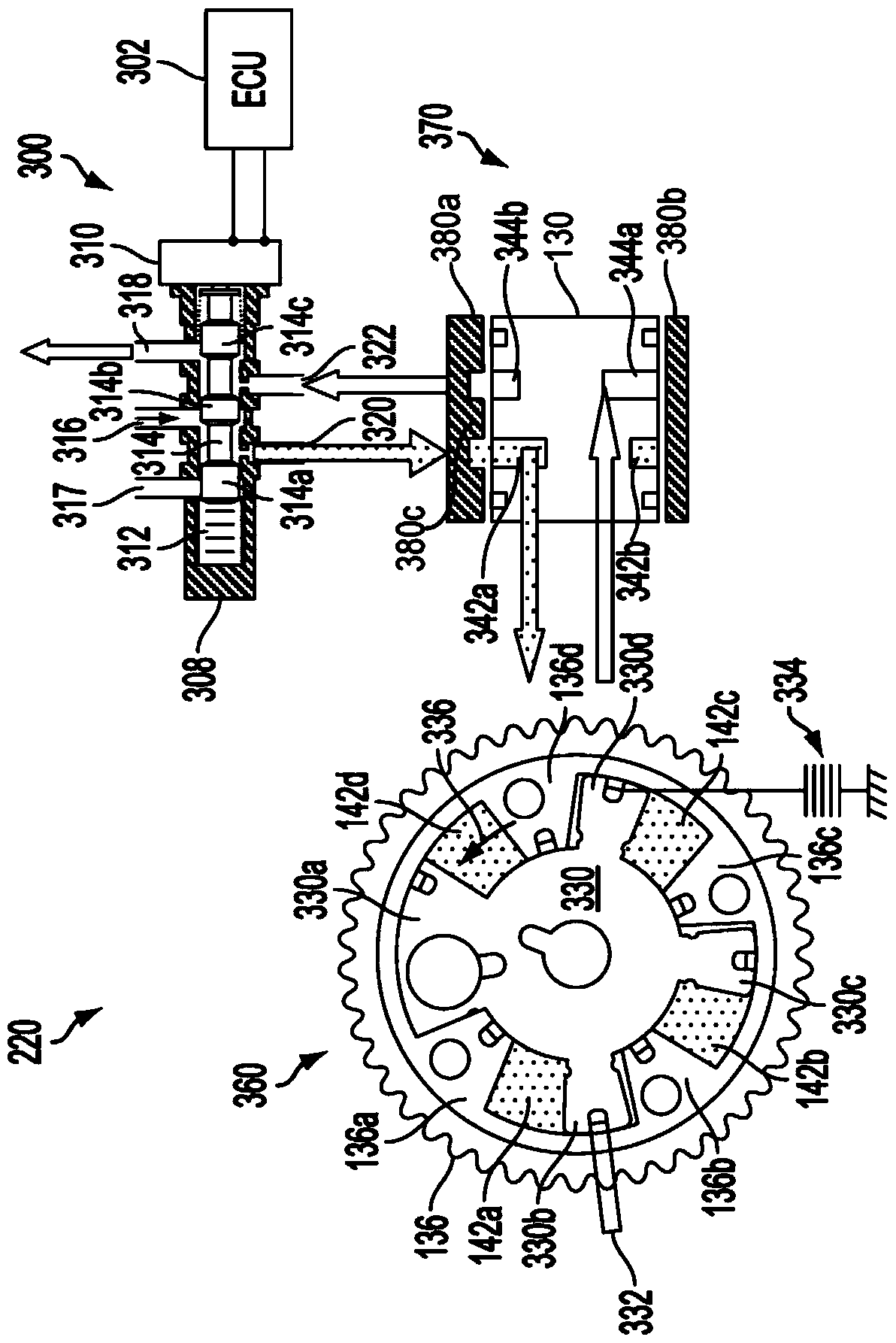

[0018] The following description relates to systems and methods for controlling a vehicle engine having a variable cylinder valve system such as variable cam timing. For example, the engine may include VCT phasers used to adjust cam timing, where the phasers are included in the hydraulic system. The engine may be configured to include a controller configured to control the actuation signal of the solenoid, thereby controlling the position of the spool valve placed within the hydraulic system. In one example, the solenoid actuation signal may be subjected to feed-forward modulation to maintain the spool valve position, thereby blocking oil from being drained from the hydraulic system, thereby improving the performance of the VCT system.

[0019] figure 1 An exemplary embodiment of a combustion chamber or cylinder of internal combustion engine 10 is described. figure 1 Engine 10 is shown as capable of receiving control parameters from a control system including controller 12 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com