Annular cylinder engine

An engine and ring cylinder technology, applied in the engine field, can solve the problems of low efficiency, unreasonable structure and heavy weight of piston engines, and achieve the effects of high efficiency, simplified engine structure, and low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

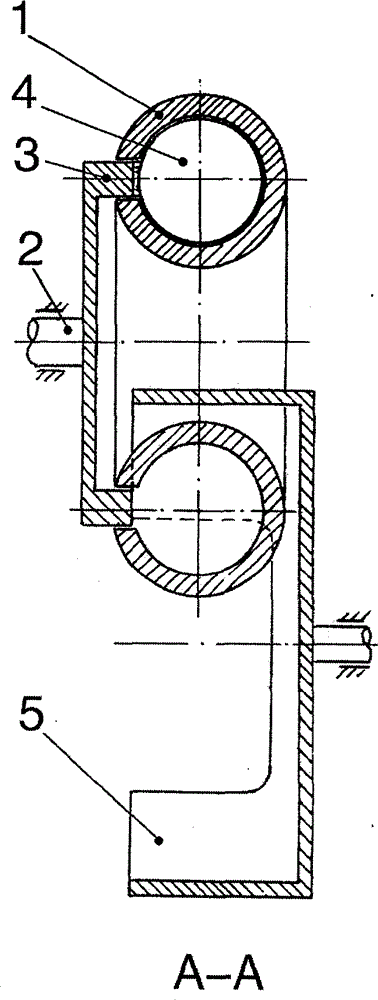

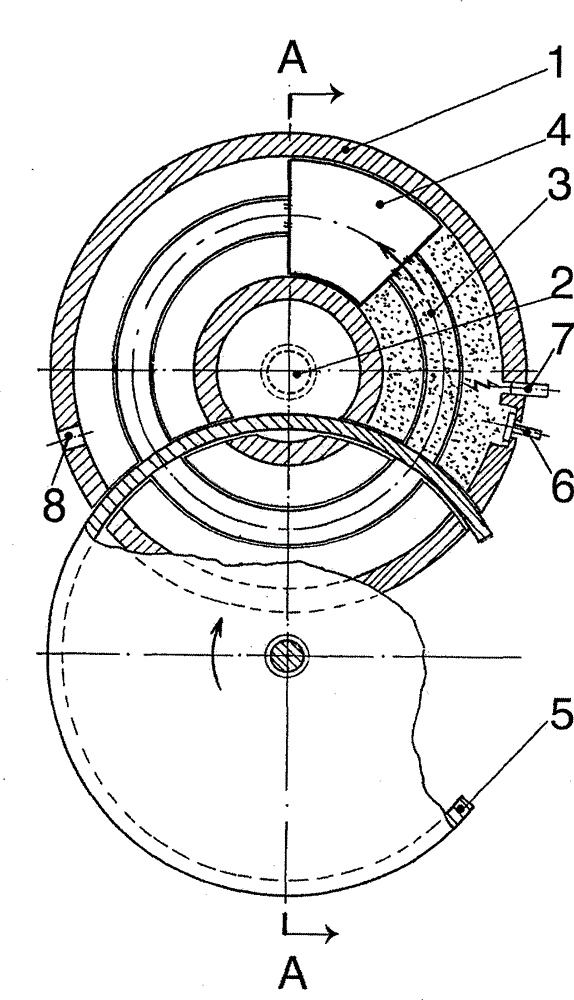

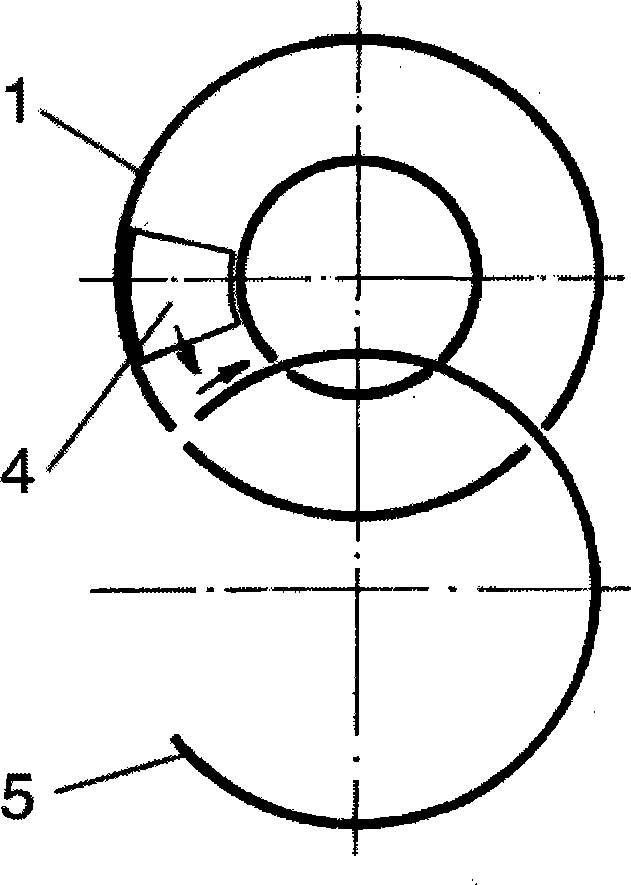

[0023] Such as figure 1 , figure 2 As shown, in the annular cylinder engine of the present invention, the center of the annular cylinder 1 is provided with a main shaft 2 and a cylindrical hub 3 thereof, and the mouth end of the hub is cut from the side of the annular cylinder to its inner cavity and is affixed to the rotary piston 4 therein. , to form a ring cylinder assembly, the inner and outer walls of the hub are in sealing and dynamic fit with the cut part of the ring cylinder, the rotating shaft is parallel to the main shaft, and the rotary drum 5 with a notch on the wall cuts into the ring cylinder from the opposite side of the hub until Its mouth end sticks to the mouth end of the shaft hub and performs a sealing and dynamic fit. The outer wall of the drum is sealed and dynamically fit with the cut part of the annular cylinder. On the outer side of the two cuts cut by the ring cylinder by the drum, an intake valve 6, Exhaust port 8, both counter-rotating pistons are...

Embodiment 2

[0025] Such as Figure 7 As shown, according to Embodiment 1, an annular cylinder assembly is provided around the drum 5, and the outer wall of the drum and the cut parts of the annular cylinders 1, the mouth end of the drum and the mouth ends of the hubs 3 are sealed and dynamically fitted. .

Embodiment 3

[0027] Such as Figure 8 As shown, according to Embodiment 1, two ring cylinder assemblies are arranged on the periphery of the rotating drum 5, and the outer wall of the rotating drum and the cut parts of each annular cylinder 1, the mouth end of the rotating drum and the mouth ends of each hub 3 are sealed dynamic. Cooperate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com