High/low-pressure sealed drill stem for hydraulic punching

A high-low pressure, punching technology, used in drill pipes, drill pipes, drilling equipment, etc., can solve problems such as water leakage at joints, and achieve the effect of convenient installation and smooth chip removal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

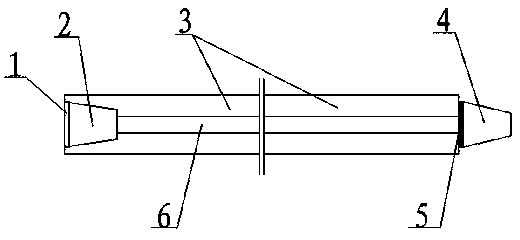

[0012] As shown in the figure, the specific implementation method is as follows:

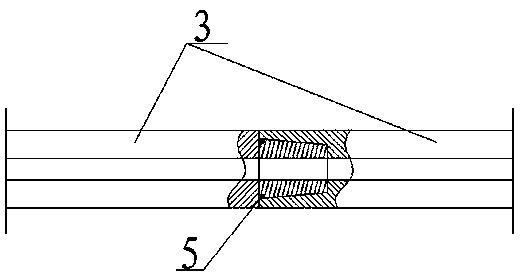

[0013] A high and low pressure sealing drill pipe for water conservancy punching, comprising a plurality of sections with a hollow rod body, including a drilling section 3, a connecting head and a connecting seat located at both ends of the drilling section 3, the connecting head It includes a tapered thread joint 4 with a tapered thread on the outer wall and a sealing section I5 that connects the tapered threaded joint 4 to the drilling section 3. The connection seat includes a tapered thread seat 2 with a tapered thread hole and cooperates with the sealing section I5. Sealed sealing section II1, the sealing section I5 includes a groove opened on the rod body and a sealing ring installed in the groove, the sealing section II1 has a smooth inner wall and a smooth surface that just forms a sealing fit with the sealing ring .

[0014] A cooling hole 6 penetrating along the length direction of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com