A roof reticulated shell structure cantilever installation method without support

A construction method and a support-free technology, which can be used in building construction, construction, and building materials processing, etc., can solve the problem of high cost, and achieve the effect of fast installation speed and saving construction period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

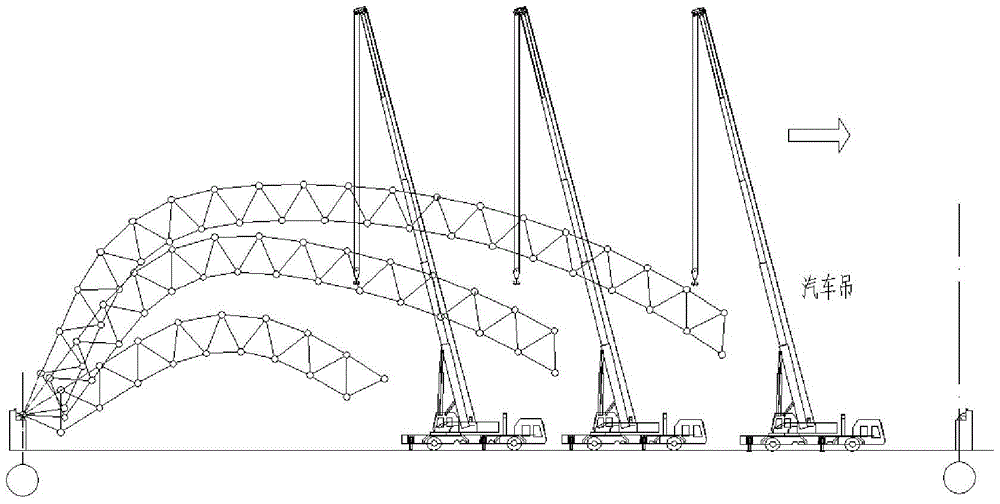

[0020] A roof reticulated shell structure cantilever installation method without supports, comprising the following steps:

[0021] Step (1) Installation of embedded parts

[0022] According to the requirements of the design drawings, the embedded parts are buried under the control of the positioning template according to the position and positioning dimensions of the drawings. In order to prevent the embedded parts from shifting during the concrete pouring process, which will adversely affect the installation of the reticulated shell, the embedded parts and The formwork is permanently fixed with fixed brackets; after the embedded parts are positioned, the measurement review is carried out immediately, and the concrete pouring construction is carried out after meeting the requirements of the specifications and design tolerances. The elevation point is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com