Mobile hot smoldering slag treatment line

A hot stuffy slag and processing line technology, applied in the field of steelmaking technology, can solve the problems of poor flexibility, large land occupation, high investment, etc., and achieve the effect of ensuring safety and flexible switching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

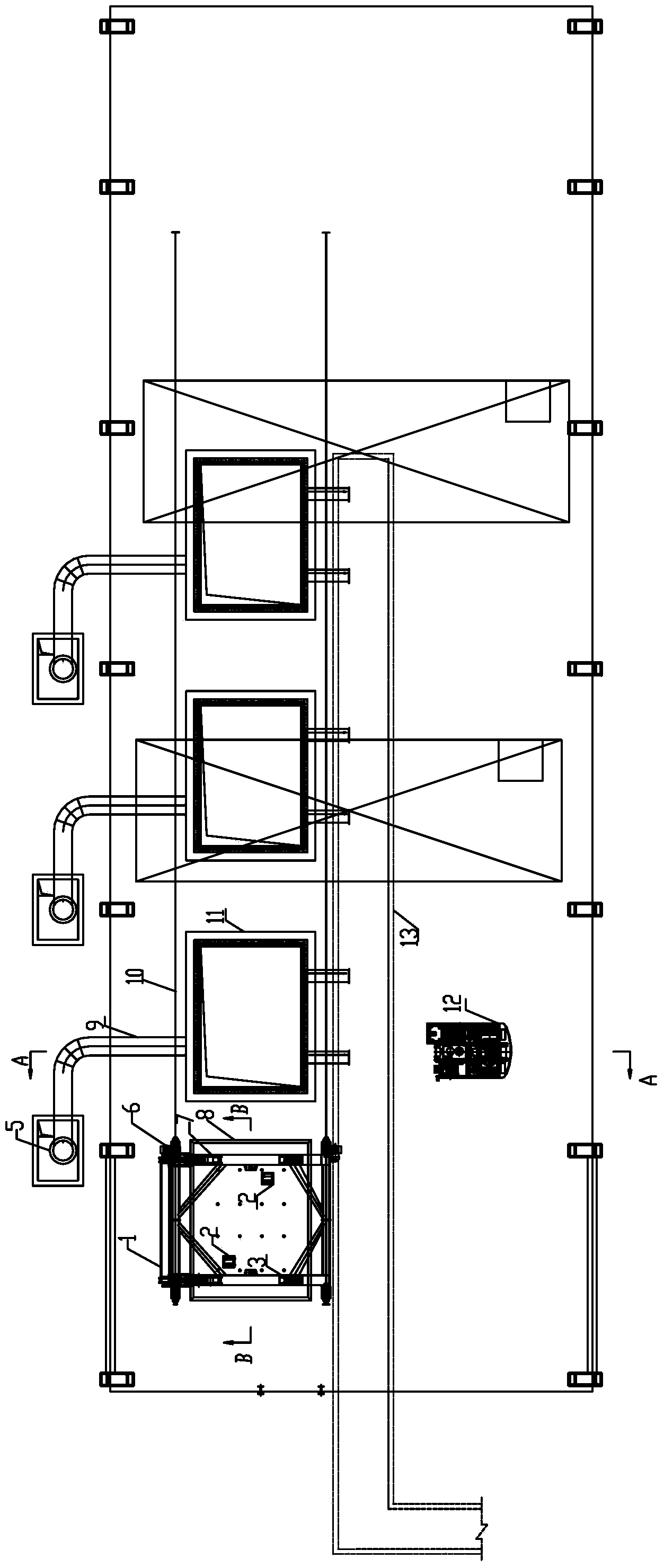

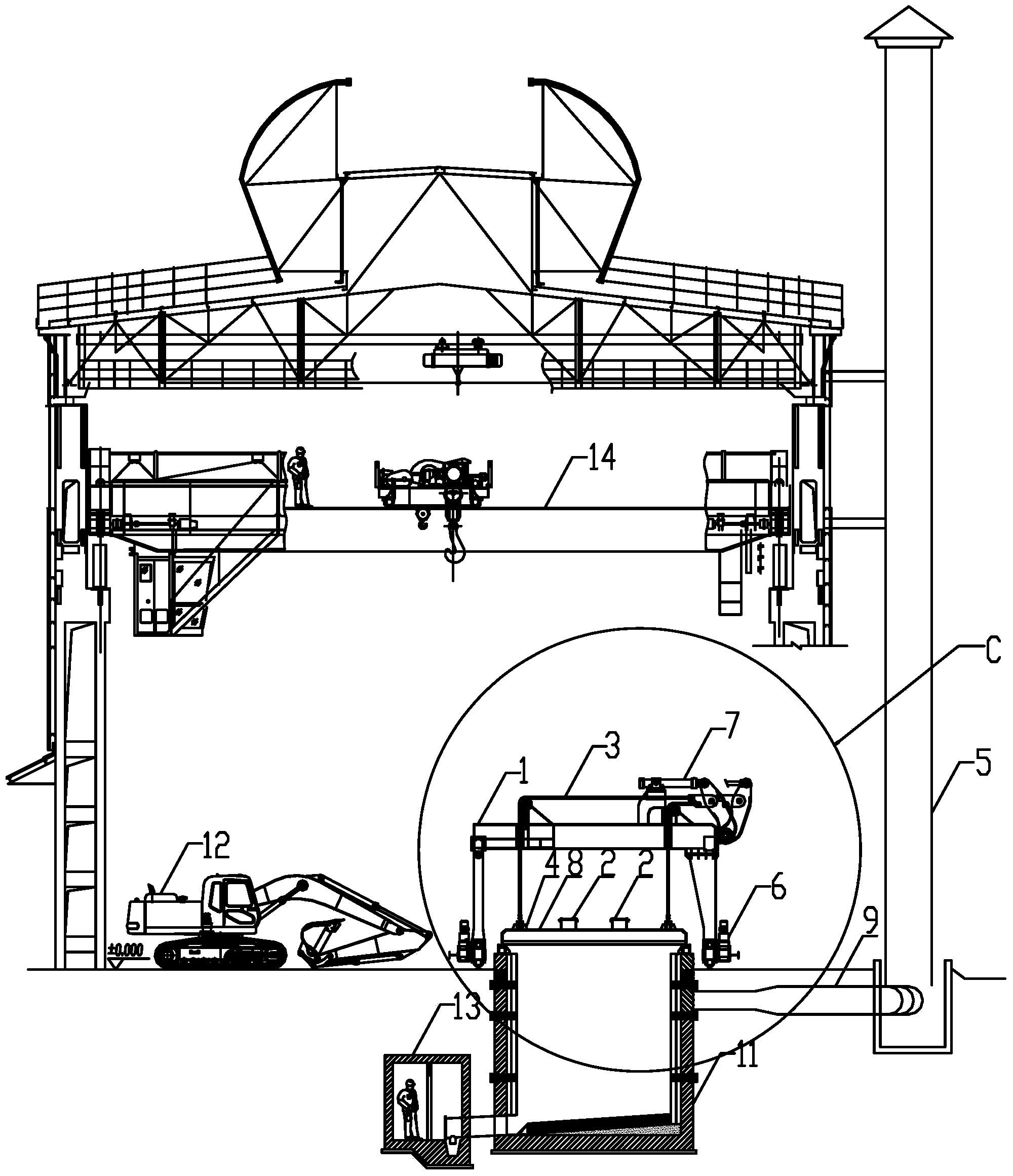

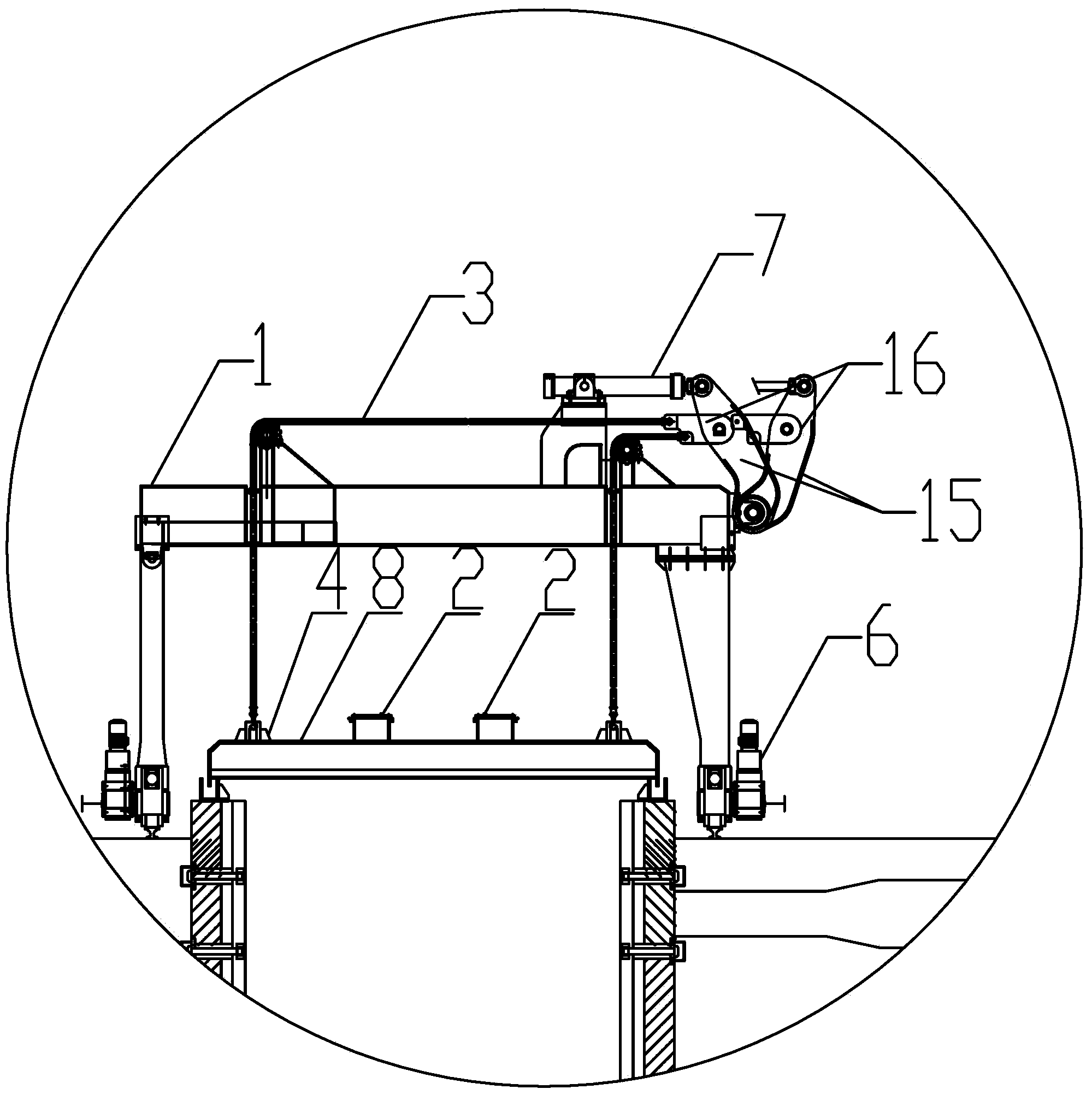

[0022] Such as Figure 1-Figure 4 As shown, a mobile hot stuffy slag processing line described in the embodiment of the present invention includes a plurality of hot stuffy slag pools 11 on the workstations of the workshop, and a plurality of steam ports are arranged on the inner wall of the hot stuffy slag pools, and the steam port The steam is released from the chimney 5 through the steam pipe 9 . A water spraying device is provided inside the hot stuffy slag pool, and the water spraying device includes a water spray nozzle arranged inside the hot stuffy slag cover. A drain is provided at the bottom of the hot stuffy slag pool, and the drain is connected to the underground water pipe gallery 13 . Two steel rails 10 are arranged on both sides of the plurality of hot stuffy slag pools, and a hot stuffy slag cover moving trolley 1 with a transmission device 6 is arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com