Piston for cabin wall vibration air hammer

An air hammer and chamber wall technology, applied in the field of pistons, can solve the problems of affecting the service life of the air hammer, reducing the rapping effect, and the entry of impurities, so as to achieve the effects of ensuring strength, prolonging service life and avoiding dry friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

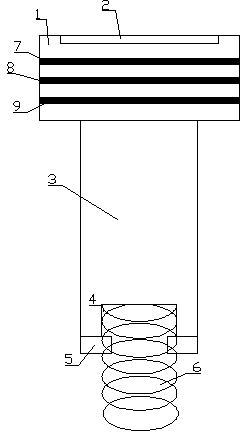

[0015] The invention discloses a piston used for vibrating an air hammer on the warehouse wall. During the use process, the problems of piston reset, sealing, lubrication and strength need to be strengthened. A magnet is arranged at the front end of the piston to ensure the timely reset of the piston. The asbestos front-stage sealing ring ensures the lubrication during the piston movement, and the post-stage sealing ring is set as a guide ring, which plays a further sealing role and plays a guiding role. At the same time, the piston material is strengthened to strengthen the piston material.

[0016] The technical solutions of the present invention are clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention, and the described embodiments are only part of the embodiments of the present invention.

[0017] The embodiment of the present invention provides a piston for rapping the air hammer of the warehouse ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com