Main reducer for coaxial dual-rotor high-speed helicopter with tension paddle

A technology of coaxial dual rotors and final reducer, which is applied to rotorcraft, aircraft, motor vehicles, etc., can solve the problems of long take-off runway and taxiing distance, limit the flight speed of helicopters, limit the flight height of helicopters, etc., and achieve the reduction of additional Effect of loss and resistance, high load, low vibration and noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

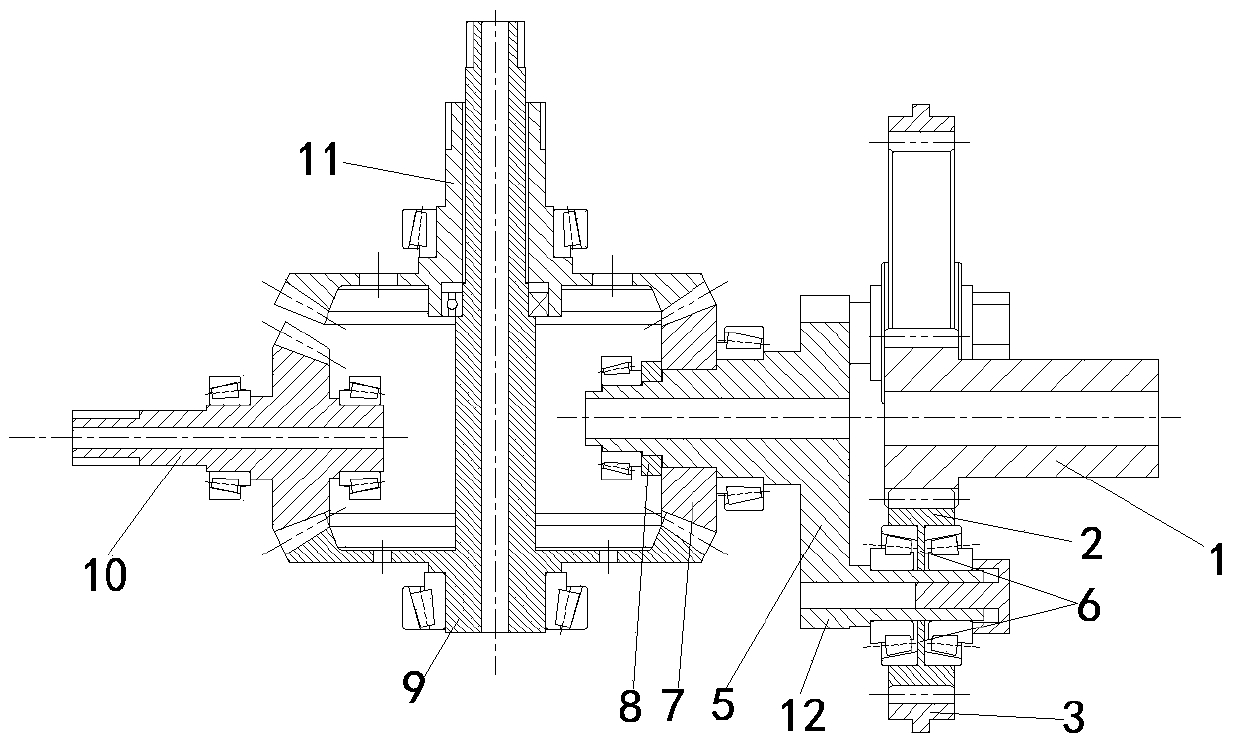

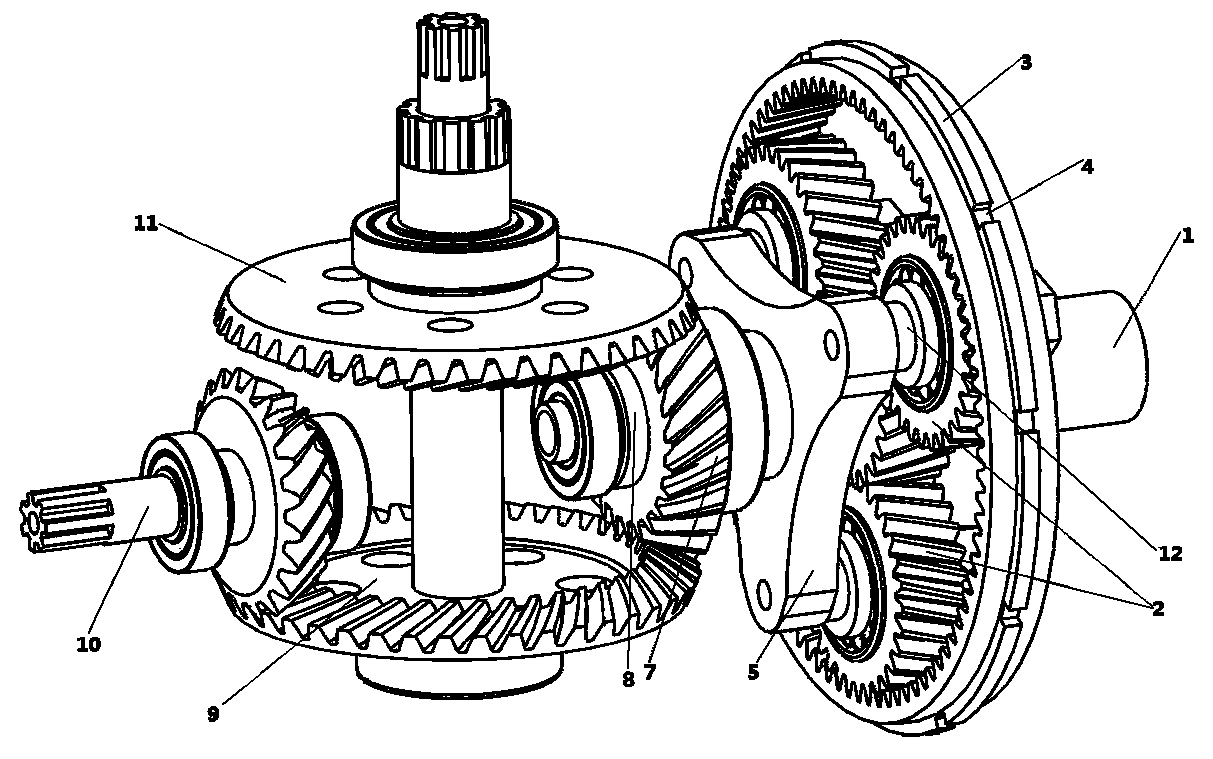

[0032] see figure 1 , figure 2 . A main reducer for a coaxial dual-rotor high-speed helicopter with a pull paddle, including a 2K-H helical planetary gear train composed of a sun gear input shaft 1, a fixed ring gear 3, three planetary gears 2 and a planet carrier 5, It also includes an input gear 7, an upper rotor gear shaft 11, a lower rotor gear shaft 9 and a pull paddle output gear shaft 10; the sun gear input shaft 1 is an involute helical gear shaft.

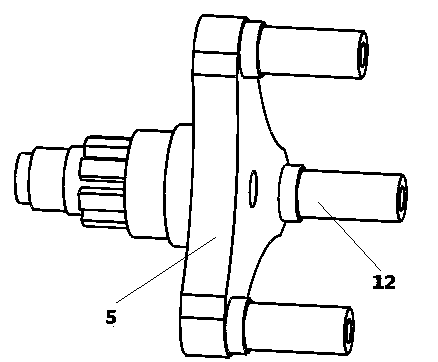

[0033] see image 3 . The main shaft at one end of the planetary carrier 5 is a shoulder shaft, the waist of the main shaft is provided with splines, and the other end of the planetary carrier 5 is provided with three planetary wheel shafts 12 .

[0034] see Figure 4 . The inner ring teeth of the fixed ring gear 3 are involute helical teeth, and the outer ring is provided with a shaft shoulder, and several key grooves 4 are evenly distributed on the shaft shoulder of the fixed ring gear 3 in the circumferential ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com