Hand-operated cam mechanism characteristic-curve drawing instrument

A characteristic curve and cam mechanism technology, which is applied to non-circular curve plotters, printing, writing utensils, etc., can solve the problems of low precision, high work intensity, and discrete points of data, and achieve reasonable design, convenient operation, and excellent structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

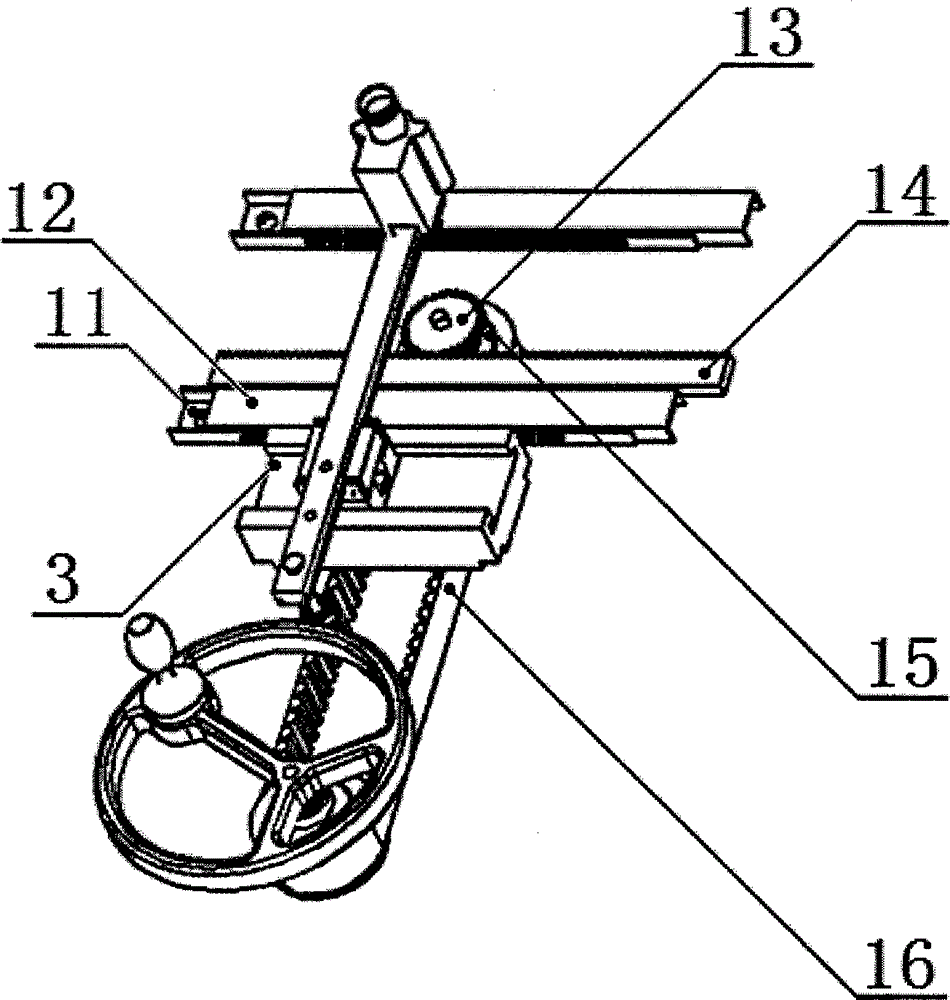

[0019] Such as figure 1 It is a schematic front view of the manual cam mechanism characteristic curve drawing instrument.

[0020] Such as figure 2 It is a schematic diagram of the positional relationship between the guide rail I, the guide rail II and the synchronous transmission mechanism.

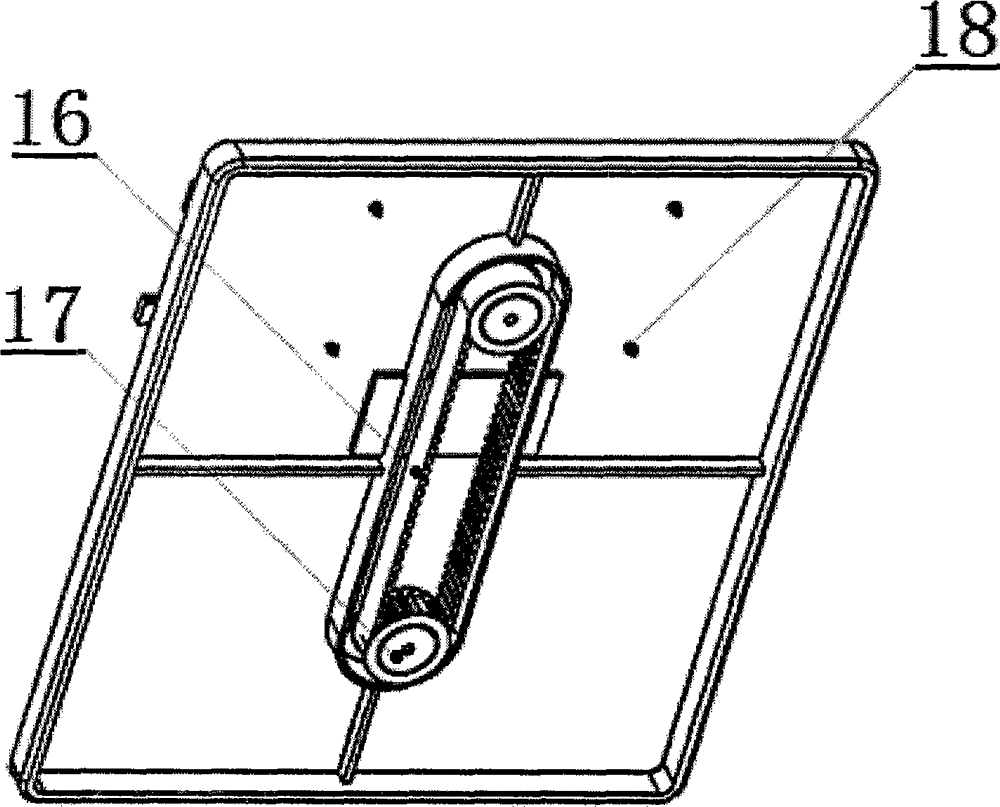

[0021] Such as image 3 It is a schematic diagram behind the positioning plate, reflecting the positional relationship between the upper synchronous pulley, the lower synchronous pulley and the positioning plate.

[0022] Described a kind of manual cam mechanism characteristic curve drawing instrument is mainly made of positioning plate (1), eccentric wheel (2), positioning block (3), ball slide bar (4), preload device (5), drawing board (6) ), guide rail I (11), guide rail II (12), moving slider group (7), handle (8), base (9), roller pin assembly (10) and synchronous transmission mechanism, the synchronous transmission mechanism It is mainly composed of a gear (13), a rack (14), a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com