Automatic laminator

A film laminating machine, automatic technology, applied in the direction of lamination device, lamination auxiliary operation, lamination, etc., can solve the problems of wrinkles, time-consuming and labor-intensive, poor lamination effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present case will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

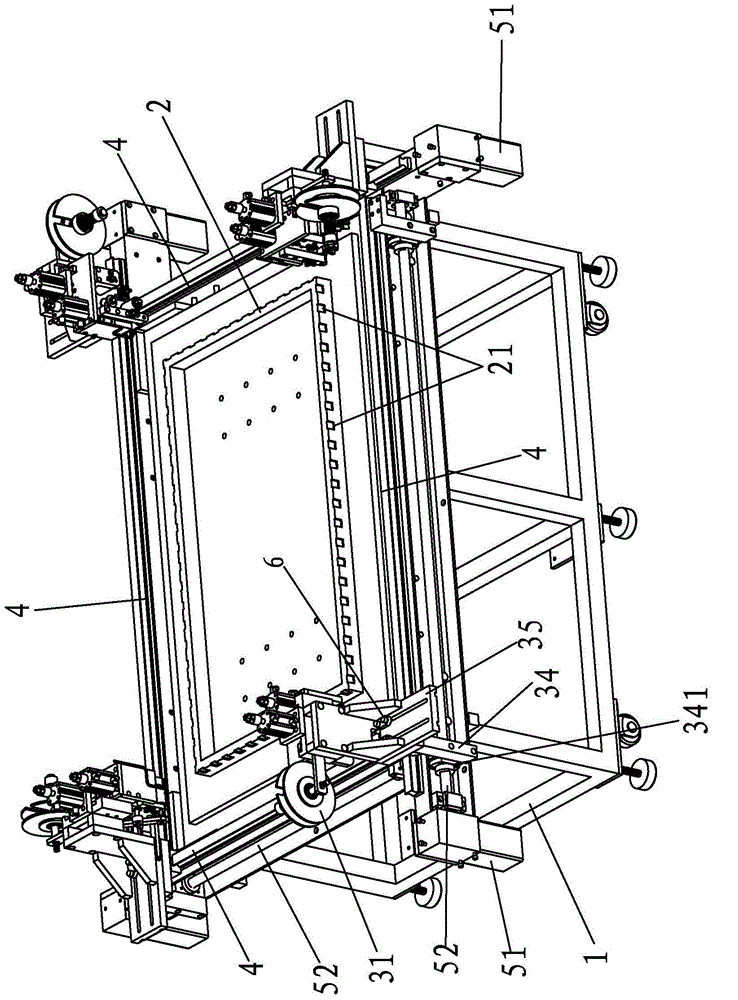

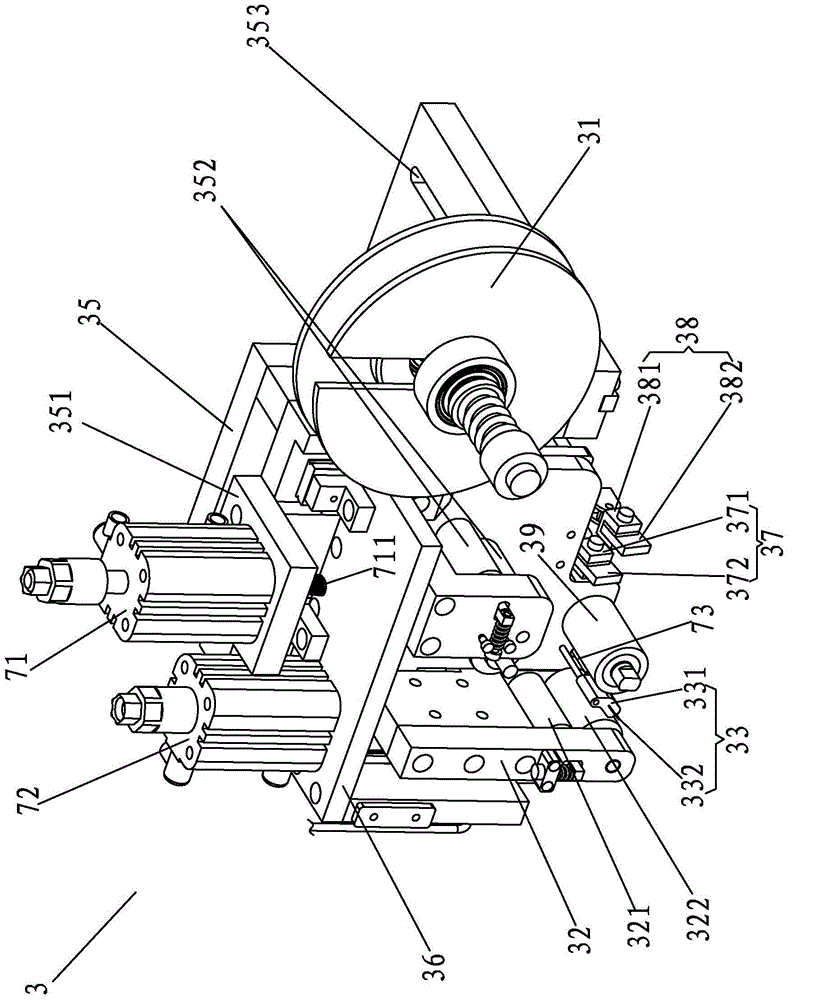

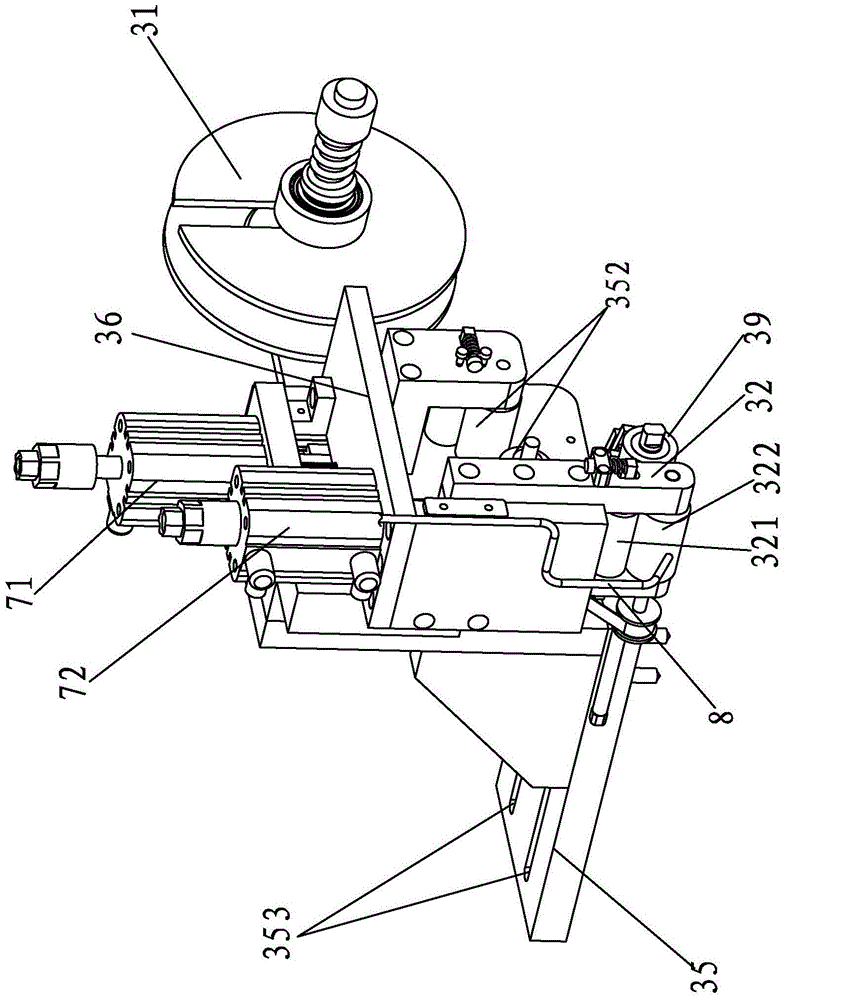

[0022] This case involves an automatic film lamination machine, such as Figure 1-4 As shown, it includes a frame 1, and the frame 1 is provided with a fixed platform 2 for detachable and fixed installation of the front frame 100. The fixed platform 2 is a square frame for the fastening and installation of the front frame 100, and the four outer edges of the square frame The upper part is respectively recessed with fastener insertion slots 21 for the respective fasteners 101 on the back of the front frame 100 to be inserted one by one. Through the cooperation of the fastener insertion grooves 21 and the fasteners 101, the front frame 100 can be horizontally placed and fixedly installed; The frame 1 is provided with a film sticking device that automatically sticks an easy-to-tear film around the outer side of the front frame 100 on the fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com