Novel peanut harvester

A peanut harvester, a new type of technology, used in excavator harvesters, harvesters, tillage machines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

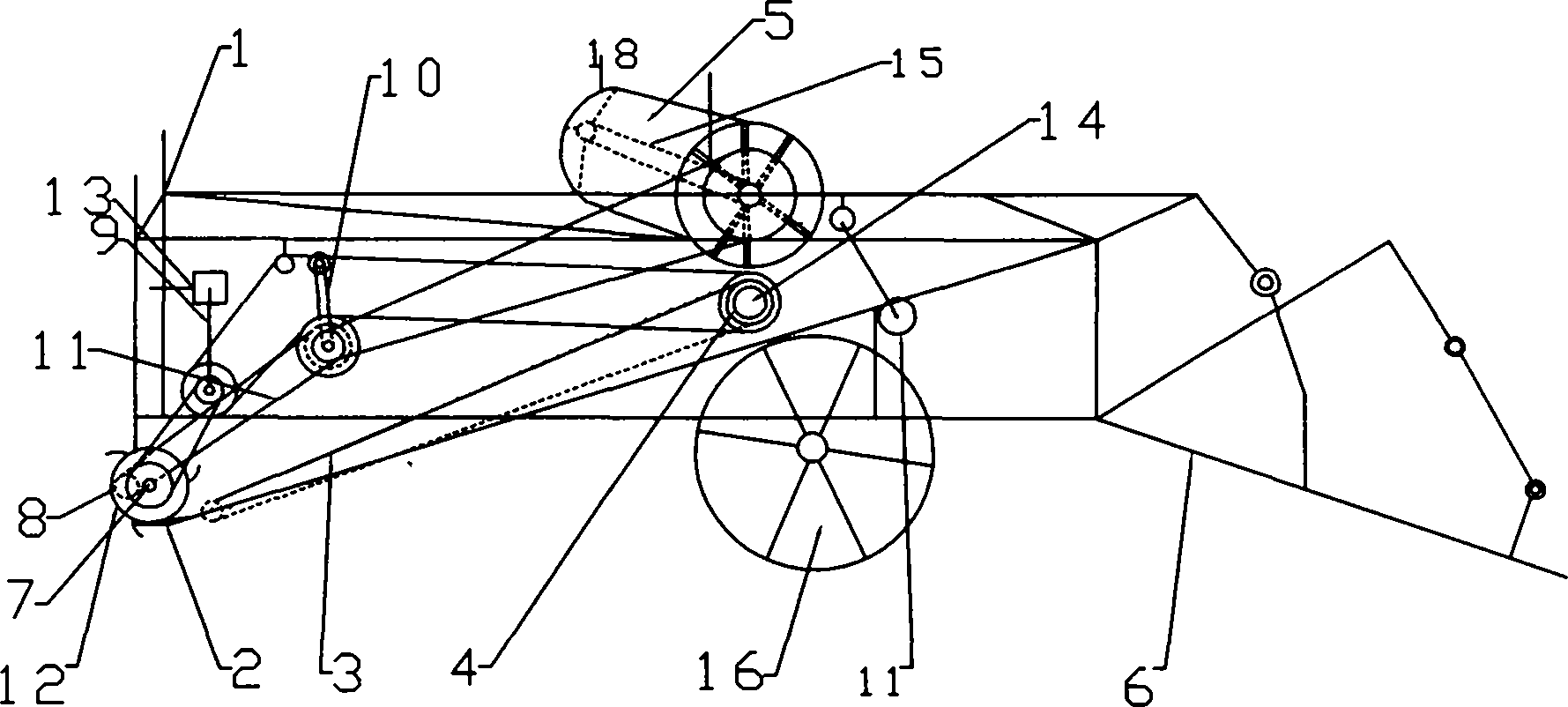

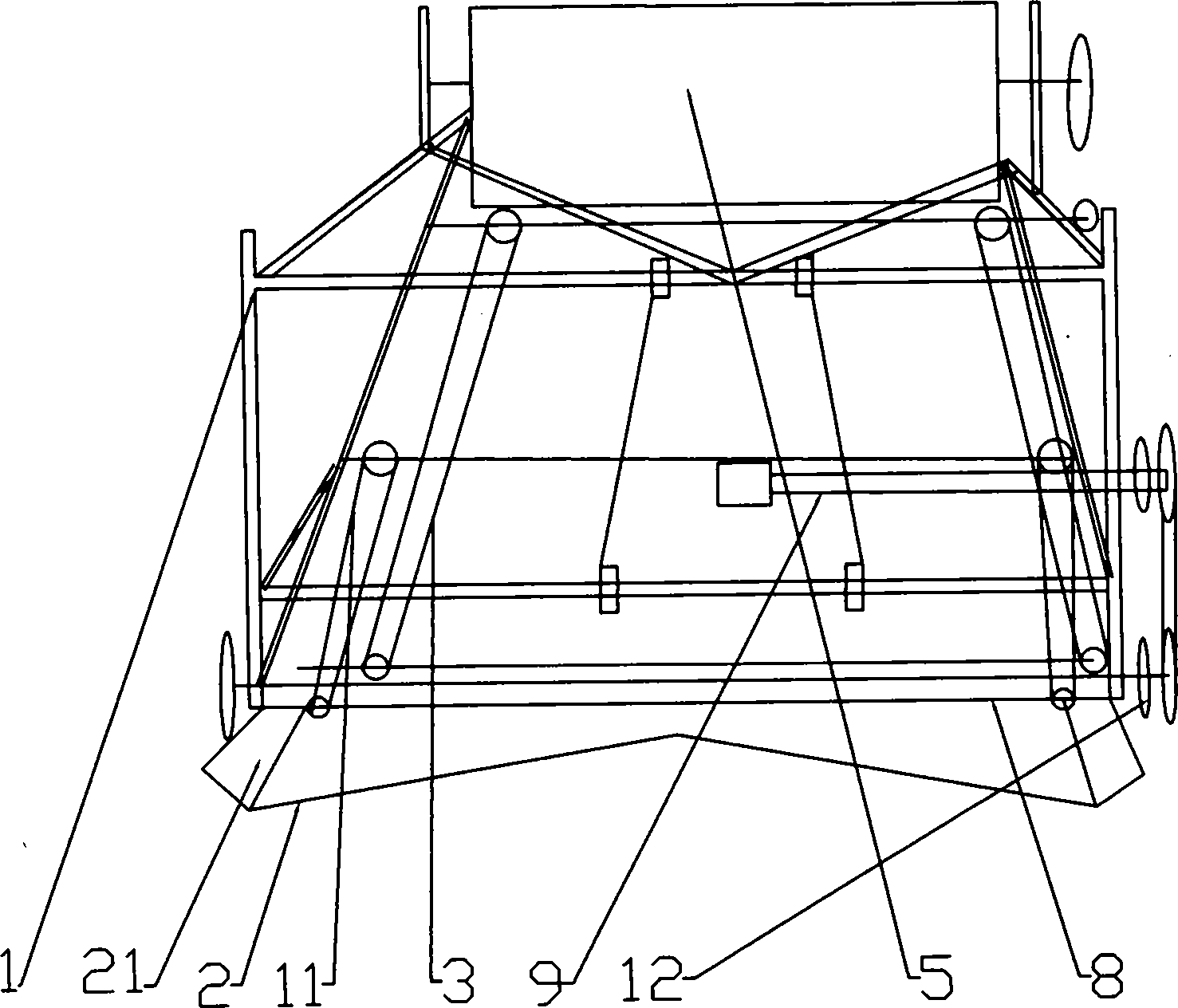

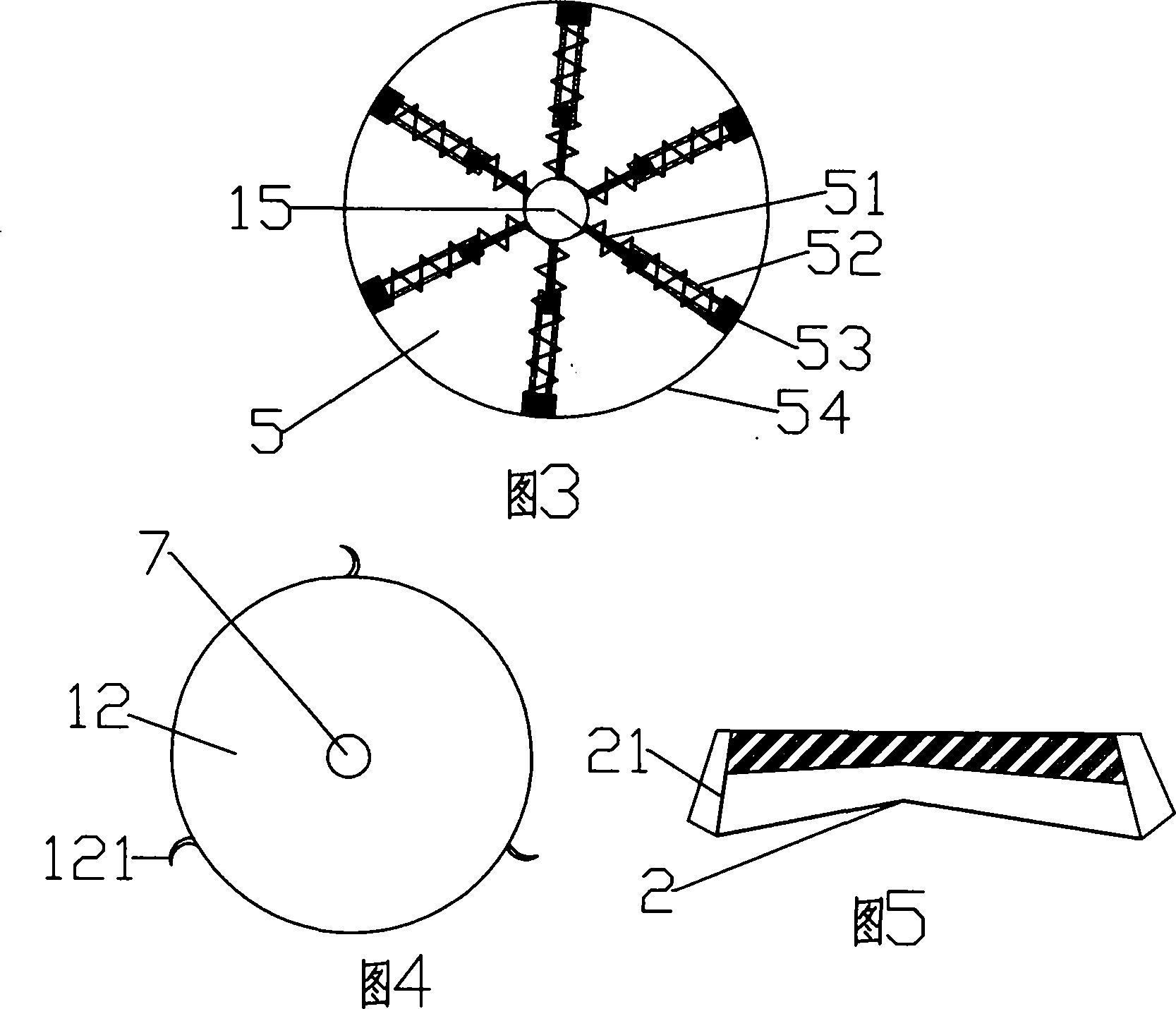

[0018] Such as figure 1 , 2 , 3, shown in 4, novel peanut harvester of the present invention is equipped with spatula (2) at the front end of frame (1) diagonal brace, and spatula (2) rear portion is provided with main conveyer belt (3), and main A drum (4) is arranged outside the power shaft at the upper end of the transmission belt (3), and a spring suppressor (5) is arranged on the upper frame cross brace of the drum (4) to be opposite to the drum (4). The end is connected to the moving screen (6), and the left side of the drum shaft 14 is connected to the left side of the moving screen (6) shaft through a swing bar; a vertical shaft 1 (7) is welded between the vertical supports of the upper frame (1) of the blade (2) , the two ends of the longitudinal axis 1 (7) are provided with seedling splitters (12), and the outer side of the right side seedling splitter is provided with a sprocket 1 connected with the outer sprocket on the main power output shaft (9); the longitudina...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com