Oil-in-water emulsified cosmetics

A technology of emulsifying cosmetics and oil-in-water type, which is applied in the direction of cosmetics, cosmetics, cosmetic preparations, etc. It can solve the problems of sticky use feeling, sedimentation, powder aggregation over time, etc., and achieves good water resistance and sweat resistance, high ultraviolet rays Defense effect, effect of suppressing stickiness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~21、 comparative example 1~17

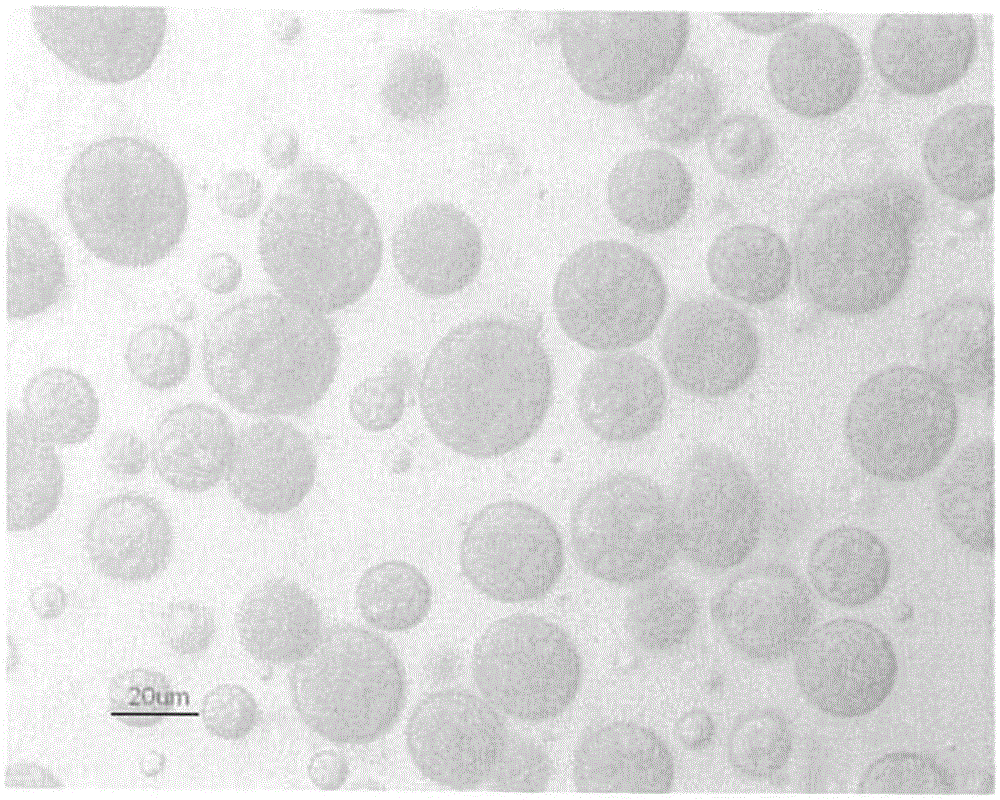

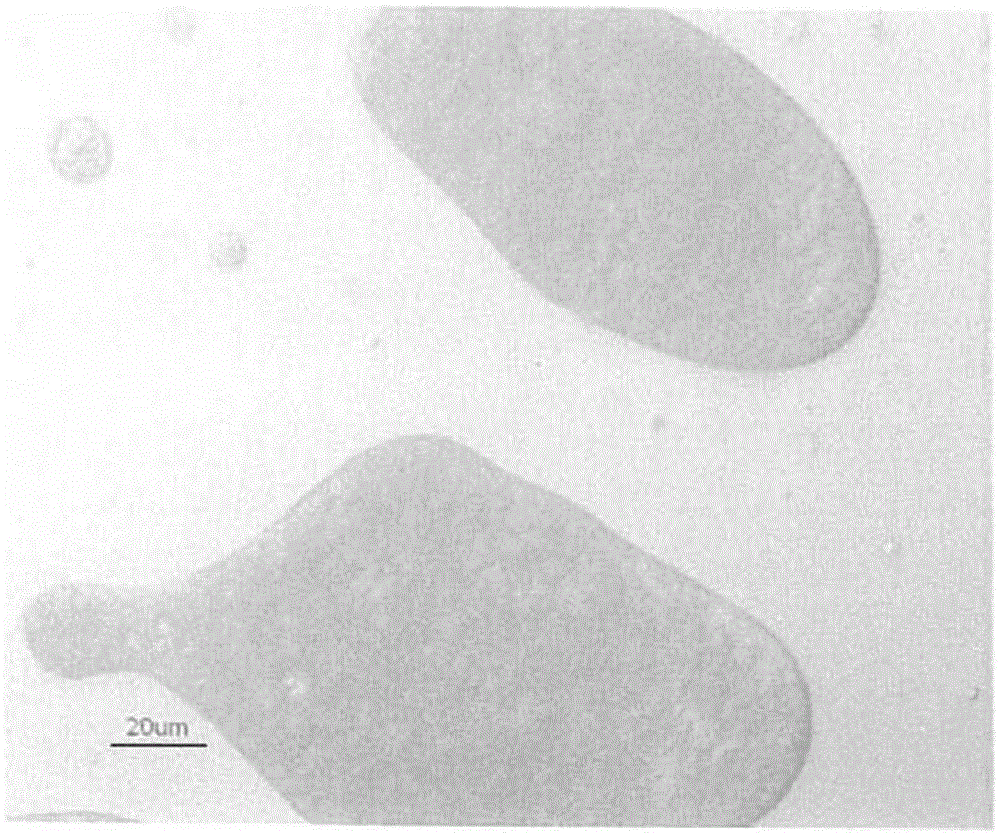

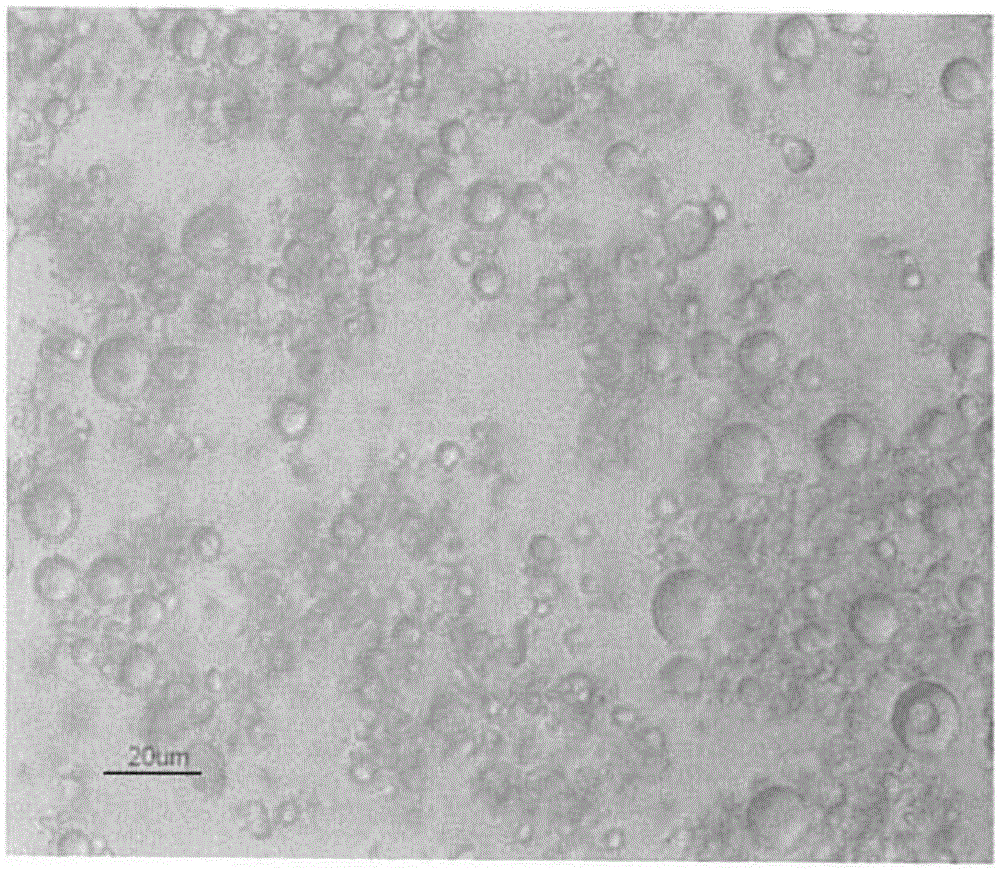

[0127] Prepare oil-in-water emulsified cosmetics according to the formulas shown in Tables 1 to 4 in accordance with common methods. Using this emulsified cosmetic, the following (1) UV protection ability durability test, (2) emulsified state test, (3) time-dependent stability test, and (4) usability test were performed. The results are shown together in Tables 1-4.

[0128] (1) UV defense ability (persistence)

[0129] Each sample shown in Tables 1 to 4 is uniformly coated on a quartz glass plate so that it becomes 2 mg / cm 2 , dry naturally for 15 minutes. Thereafter, the quartz glass plate coated with the sample was irradiated with ultraviolet light from a certain distance (10 mm). The transmitted ultraviolet rays at this time were detected at more than 6 positions on the quartz glass plate in the range of 290 to 400 nm with an SPF analyzer (Optometices Co.), and the averaged spectrum was obtained to calculate the SPF value.

[0130] After that, each of the sample-coated...

manufacture example 1

[0171] (Production Example 1 Silicone Surface Treatment Microparticle Zinc Oxide Powder Production)

[0172] After putting 88 parts by mass of microparticle zinc oxide powder (approximately spherical, with an average particle diameter of 0.016 μm) and 12 parts by mass of dimethylpolysiloxane (20cSt, manufactured by Shin-Etsu Chemical Co., Ltd.) into toluene and stirring uniformly, Toluene was removed by heating under reduced pressure. The obtained powder was pulverized with an atomizer. Next, firing treatment was performed at 800° C. in air for 2 hours using a high-temperature heating furnace to obtain a silicone surface-treated fine particle zinc oxide powder.

manufacture example 2

[0173] (Production Example 2 Production of Methylhydropolysiloxane Surface-treated Microparticle Zinc Oxide Powder)

[0174] Prepare a slurry consisting of 93 parts by mass of fine-particle zinc oxide powder (roughly spherical, with an average particle size of 0.02 μm), 7 parts by mass of methylhydrogenpolysiloxane (KF-99P, manufactured by Shin-Etsu Chemical Co., Ltd.), and isopropyl alcohol After fully stirring and pulverizing the material, the solvent was distilled off under reduced pressure, and heat treatment was carried out at 150° C. in air for 4 hours to obtain a methyl hydrogen polysiloxane surface-treated microparticle zinc oxide powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com