Reactive in-place intelligent compensation device for three-phase asynchronous motor

A three-phase asynchronous, electric motor technology, applied in reactive power compensation, reactive power adjustment/elimination/compensation, AC motor control, etc., can solve the problems of large installation area, difficult integration, low compensation efficiency, etc., to achieve convenient installation And use, prolong service life, improve the effect of compensation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

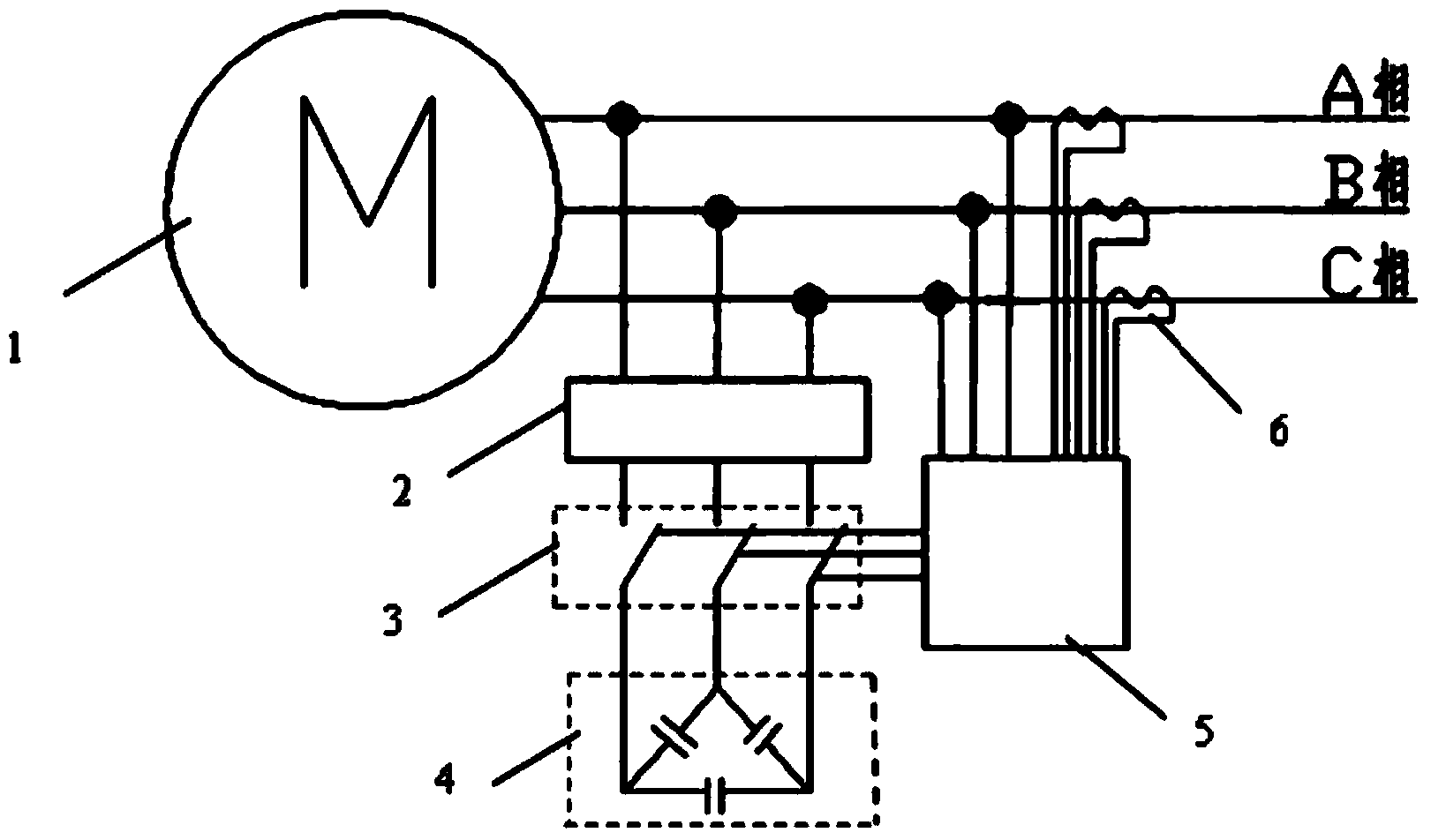

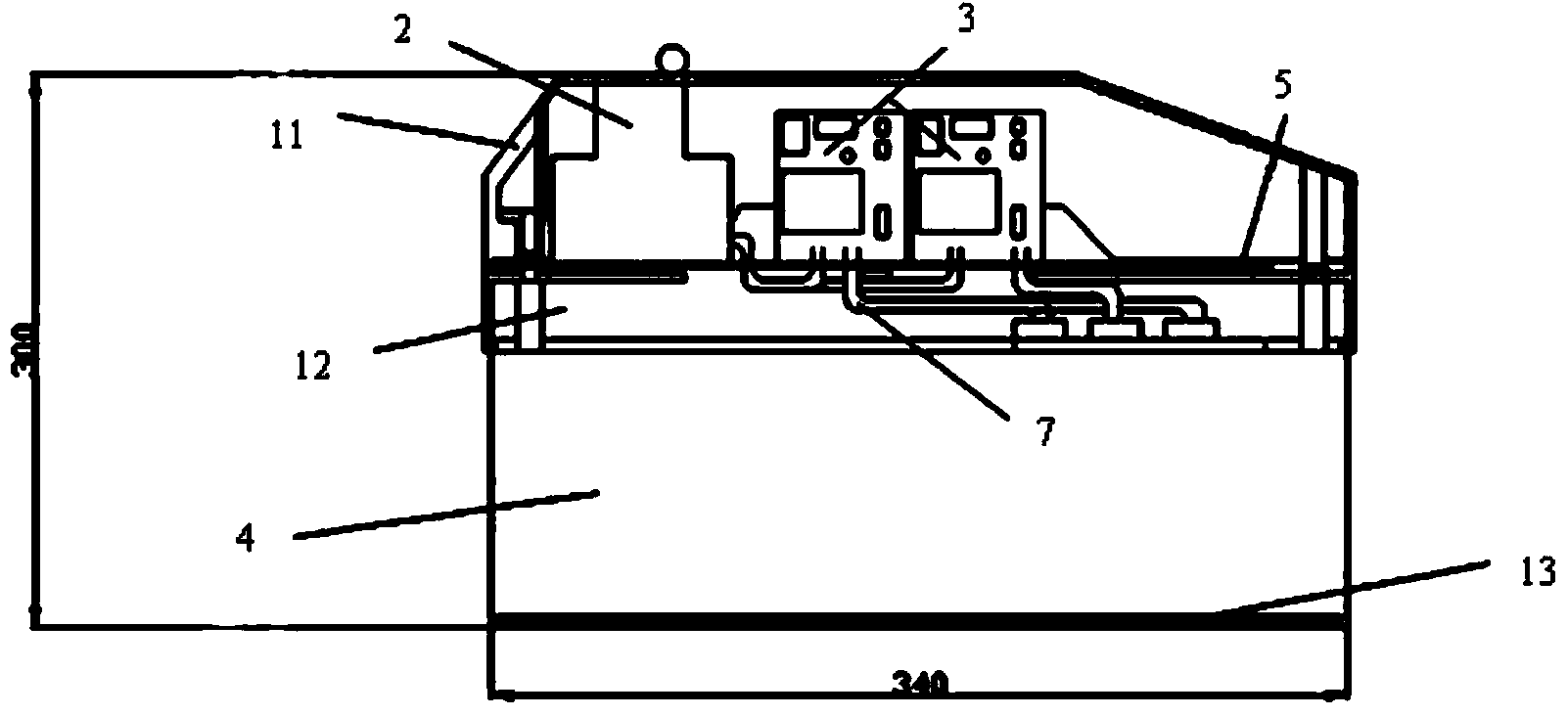

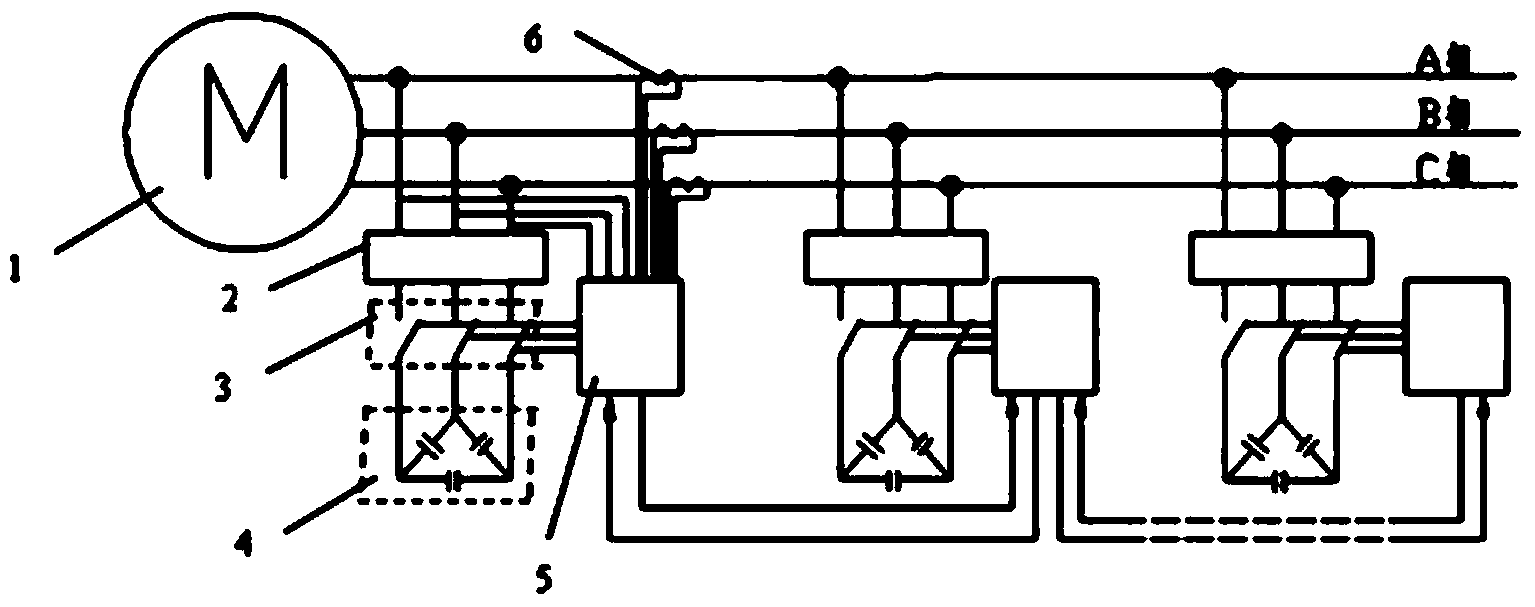

[0019] The invention provides a device for reactive power in-situ intelligent compensation of three-phase asynchronous motors, figure 1 It is a schematic diagram of a single device connected to a three-phase asynchronous motor for reactive power on-site intelligent compensation of a three-phase asynchronous motor according to the present invention. In the figure, it can be seen that the device includes a dry-type low-voltage power capacitor 4 and a high breaking capacity circuit breaker 2 , soft switching switch 3 and DSP chip controller 5. The dry-type low-voltage power capacitor 4 is connected in delta with three capacitors, and the three capacitors are connected in parallel with the AB phase, BC phase, and AC phase of the input three-phase alternating current of the motor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com