Stack type image sensor manufacturing method

An image sensor and stacking technology, which is applied in the field of stacked image sensor preparation, can solve the problems of affecting the output image quality, long process cycle, cumbersome steps, etc., and achieve the effects of improving image output quality, reducing production costs, and simplifying process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] This embodiment provides a method for a stacked image sensor, and the specific steps are as follows:

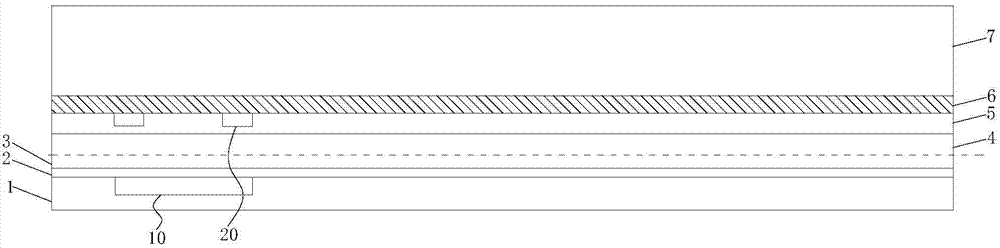

[0062] Step S1: providing a semiconductor device, the semiconductor device includes a logic wafer (logic wafer) and a device wafer (pixel wafer, or pixel wafer) bonded on the logic wafer, the logic wafer is embedded with a second A metal electrode, a second metal electrode is embedded in the device wafer.

[0063] Specifically, firstly, a logic wafer and a device wafer are provided, and the device wafer is bonded on the upper surface of the logic wafer. Wherein, both the logic wafer and the device wafer are provided with multi-layer oxide layers, and a silicon layer is provided on the top of the device wafer, and the first metal electrode is embedded in one of the oxide layers of the logic wafer, and includes the The upper surface of the oxide layer of the first metal electrode is covered with a mask layer, and the second metal electrode is embedded in one of the oxid...

Embodiment 2

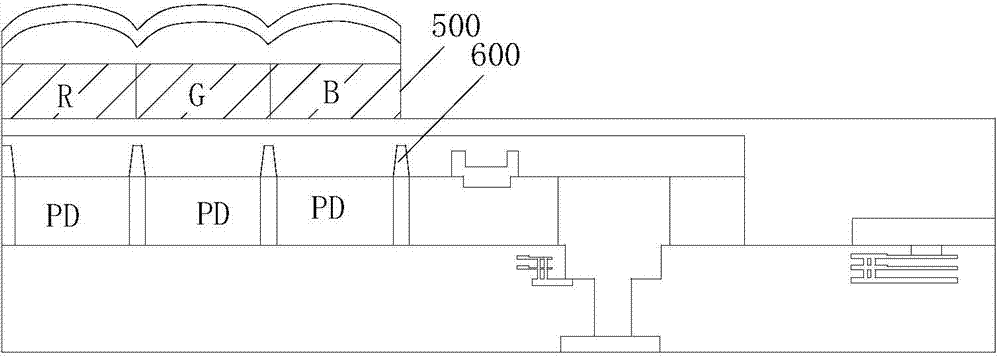

[0076]Based on the first embodiment above, the present application also provides a stacked image sensor prepared by the above preparation method, including a filter layer and a metal grid, and the filter layer is embedded in the metal grid, and can be combined with conventional Other device structures together form a stacked image sensor, that is, in this embodiment, by embedding the filter layer in the metal grid, the crosstalk phenomenon in the PD layer can be effectively avoided, thereby improving the output quality of the image , and compared with the traditional device structure, its preparation process can be greatly simplified to reduce its production cost, and it can be widely used in electronic image equipment such as mobile phones, digital cameras, and DVs.

Embodiment 3

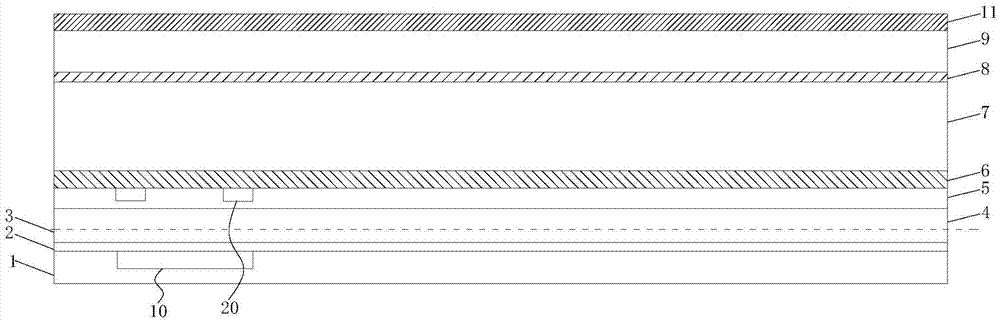

[0078] This embodiment provides a method for preparing a stacked image sensor, and the specific steps are as follows:

[0079] Step S1: Provide a semiconductor device for preparing a stacked image sensor, the semiconductor device includes a logic wafer (logic wafer) and a device wafer (pixel wafer, or pixel wafer) bonded on the logic wafer , the first metal electrode is embedded in the logic wafer, and the second metal electrode is embedded in the device wafer.

[0080] Specifically, firstly, a logic wafer and a device wafer are provided, and the device wafer is bonded on the upper surface of the logic wafer. Wherein, both the logic wafer and the device wafer are provided with multi-layer oxide layers, and the top of the device wafer is also provided with a silicon layer, and the first metal electrode is embedded in one of the oxide layers of the logic wafer, and The upper surface of the oxide layer including the first metal electrode is covered with a mask layer, and the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com