Installing structure and process for vacuum switch tube

A technology of vacuum switch tube and installation structure, which is applied to electric switches, high-voltage/high-current switches, high-voltage air circuit breakers, etc., can solve the problems of installation difficulty, damage to bellows, affecting the sealing performance of insulating cylinders, etc., and achieve a simple installation structure. , reliable connection, cleverly designed effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

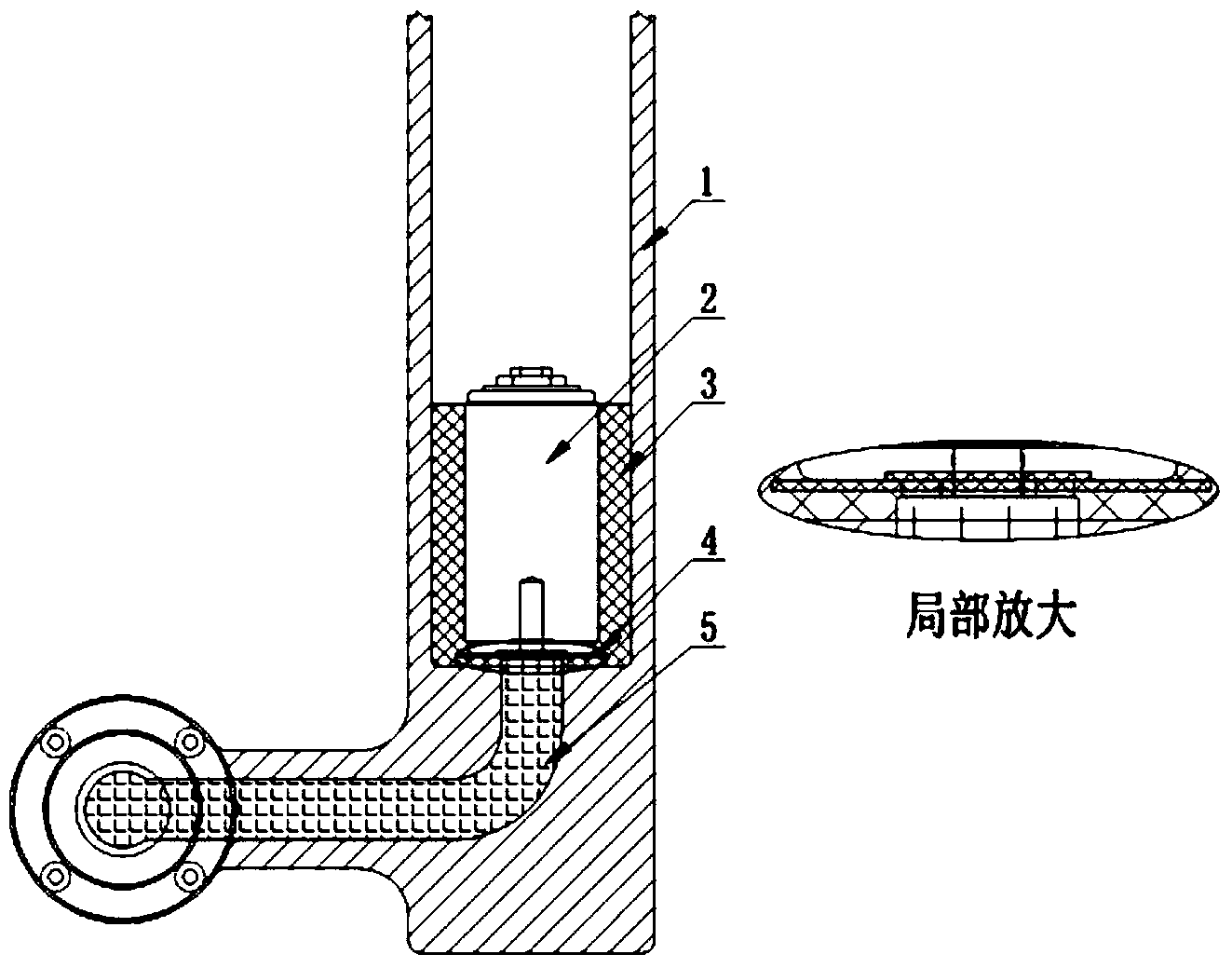

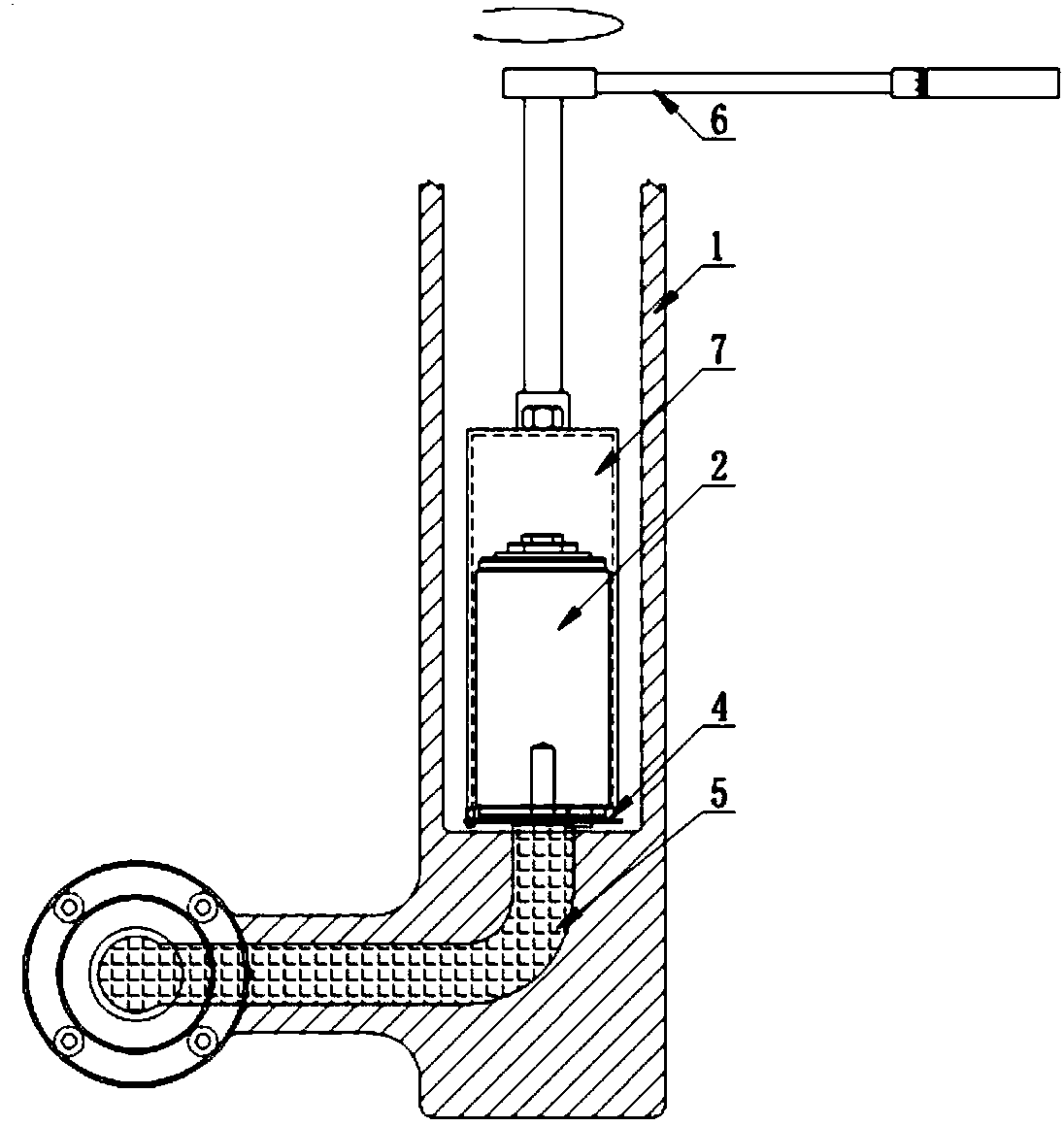

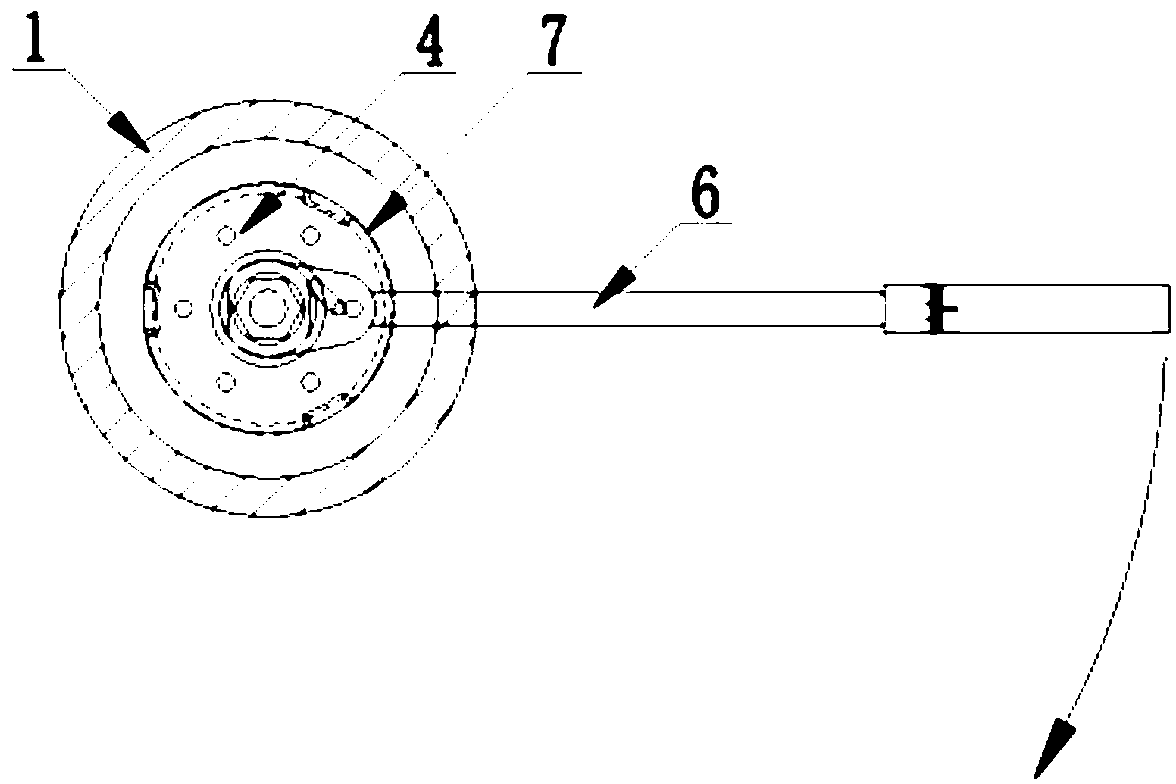

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0020] like Figure 1 to Figure 6 As shown, the installation structure of the vacuum switch tube of the present invention includes a specially designed circular plate 4 and a special sleeve 7 . Described circular plate 4 is formed by injection molding of polycarbonate material, and shape is as Figure 5 shown. Polycarbonate has good impact resistance and thermal distortion resistance, and has good weather resistance and high hardness. It will not be deformed or broken under the rotational force of 35-40N, which can meet the installation requirements of the vacuum switch tube 2, and it is a A good flame-retardant and insulating material will not affect the withstand voltage and partial discharge performance of the main body of the cabinet if it is left on the static contact 2-2 of the vacuum switch tube. The shape of the middle part of the circular plate 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com