A Calibration Method of Single-axis Fluxgate Sensor Parameters

A technology of fluxgate sensor and calibration method, which is applied in the direction of instruments, measuring devices, measuring electric variables, etc., can solve the problems of complicated calibration process and low calibration accuracy of single-axis fluxgate sensor parameters, and achieve simple calibration process and high parameter accuracy. The effect of high precision and high calibration precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

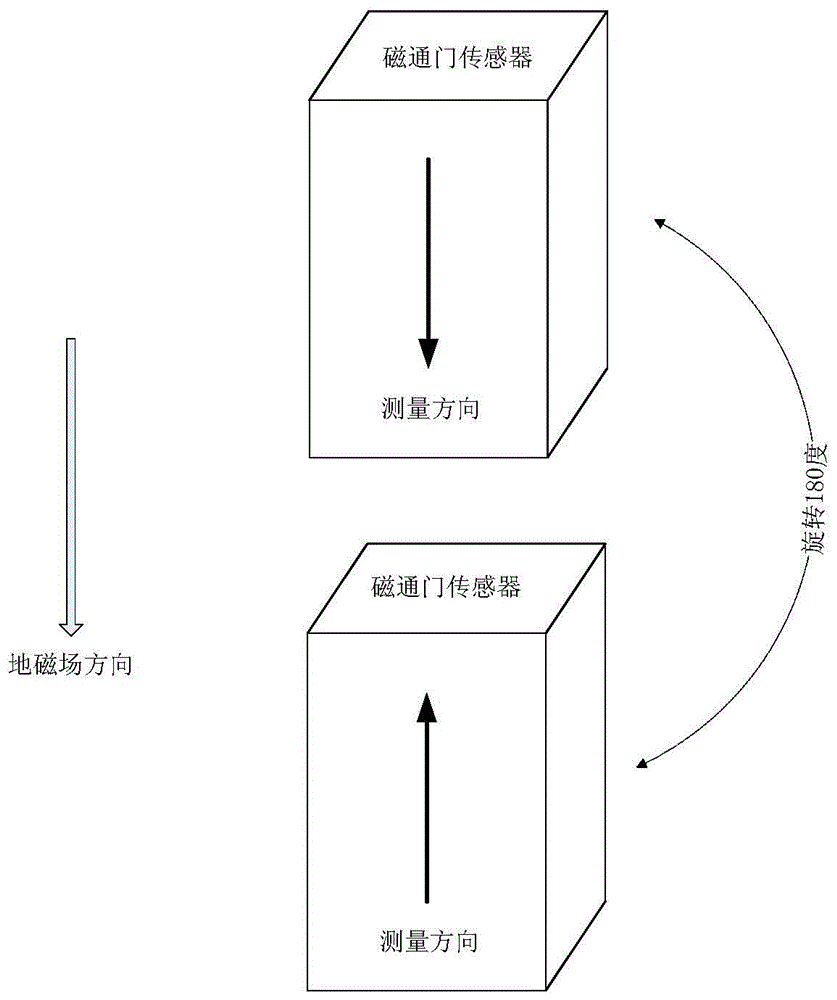

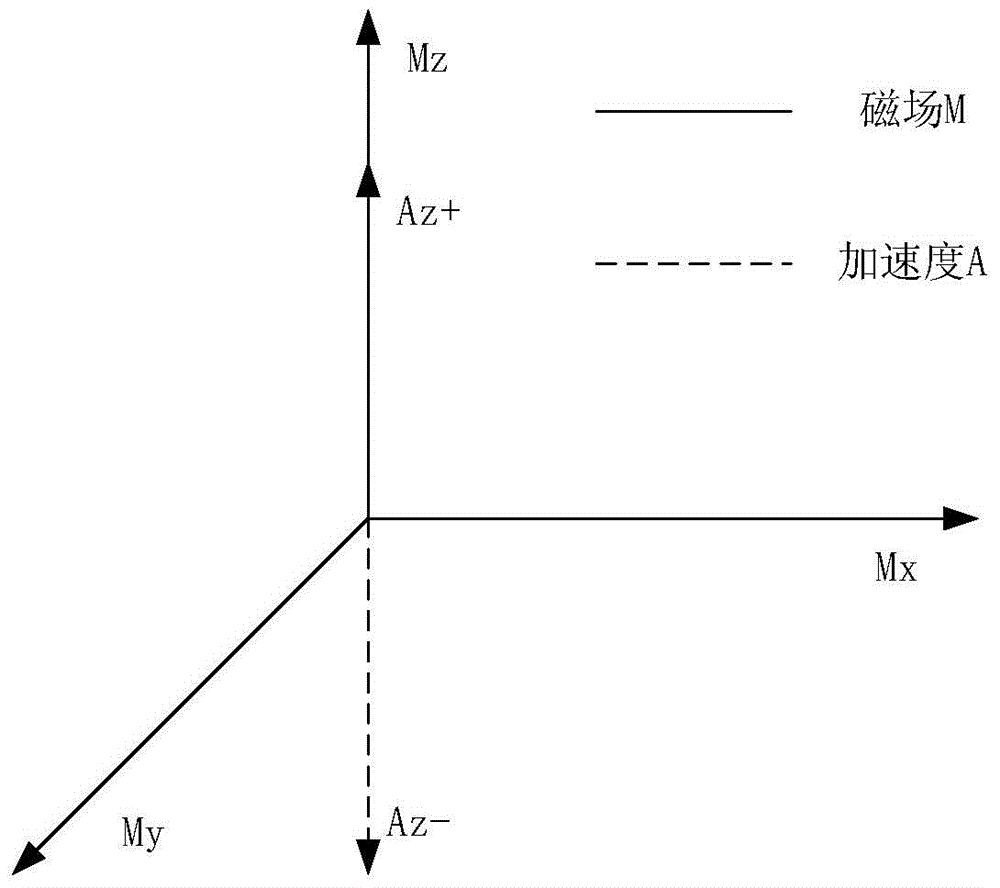

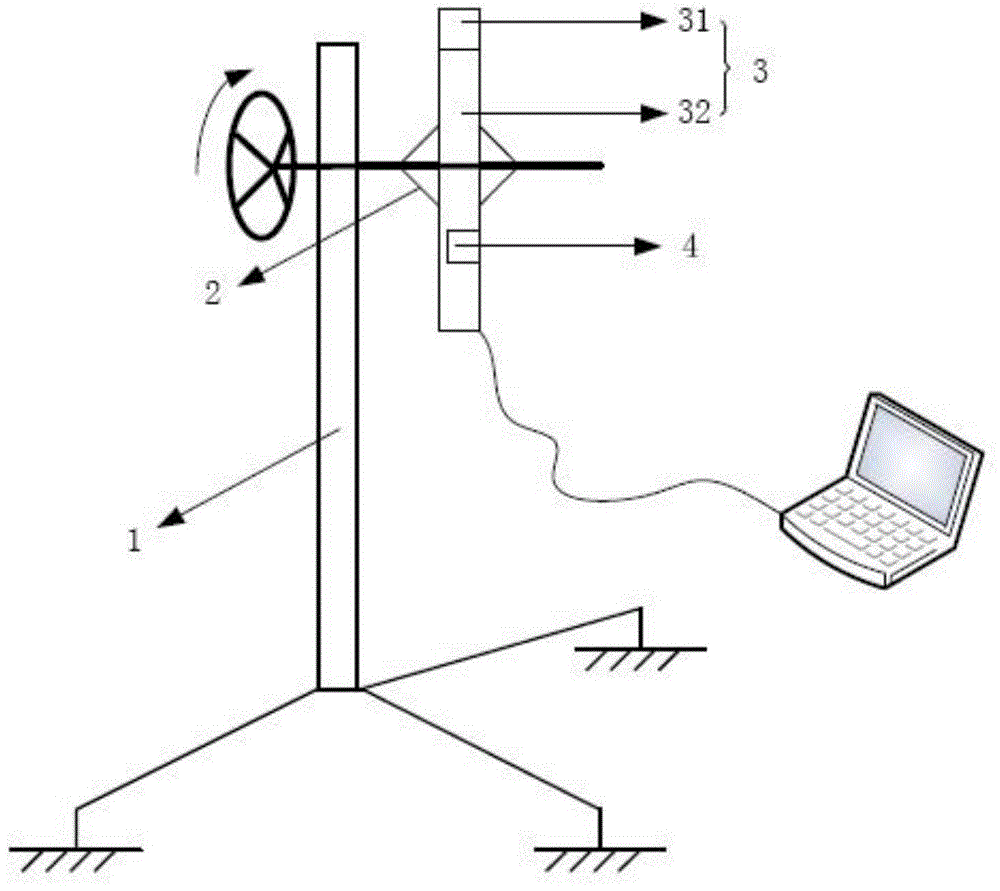

[0022] Such as Figure 1-Figure 3 As shown, a method for calibrating parameters of a uniaxial fluxgate sensor 3, the uniaxial fluxgate sensor 3 is composed of a probe 31 and a signal processing board 32, and the calibration method includes the following steps:

[0023] Step 1. Select the measurement site where the JJP-2 calibration station 1 is placed. The measurement site generally chooses parks, playgrounds, etc. with little external magnetic interference; use the earth's magnetic field model, and calculate the day's measurement according to the longitude and latitude of the measurement site and the measurement time. The values of the three components of the geomagnetic field at the location of the earth. For example, taking the location at an altitude of 20 meters, 31°15′16 north latitude and 121°22′18 east longitude as the measurement site, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com