Bearing and method of collecting a lubricant leaking out of a bearing

A technology for lubricants and bearings, applied in the field of improved bearings, can solve problems such as ecological damage, unpleasant appearance of lubricants, etc., and achieve the effect of large axial force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

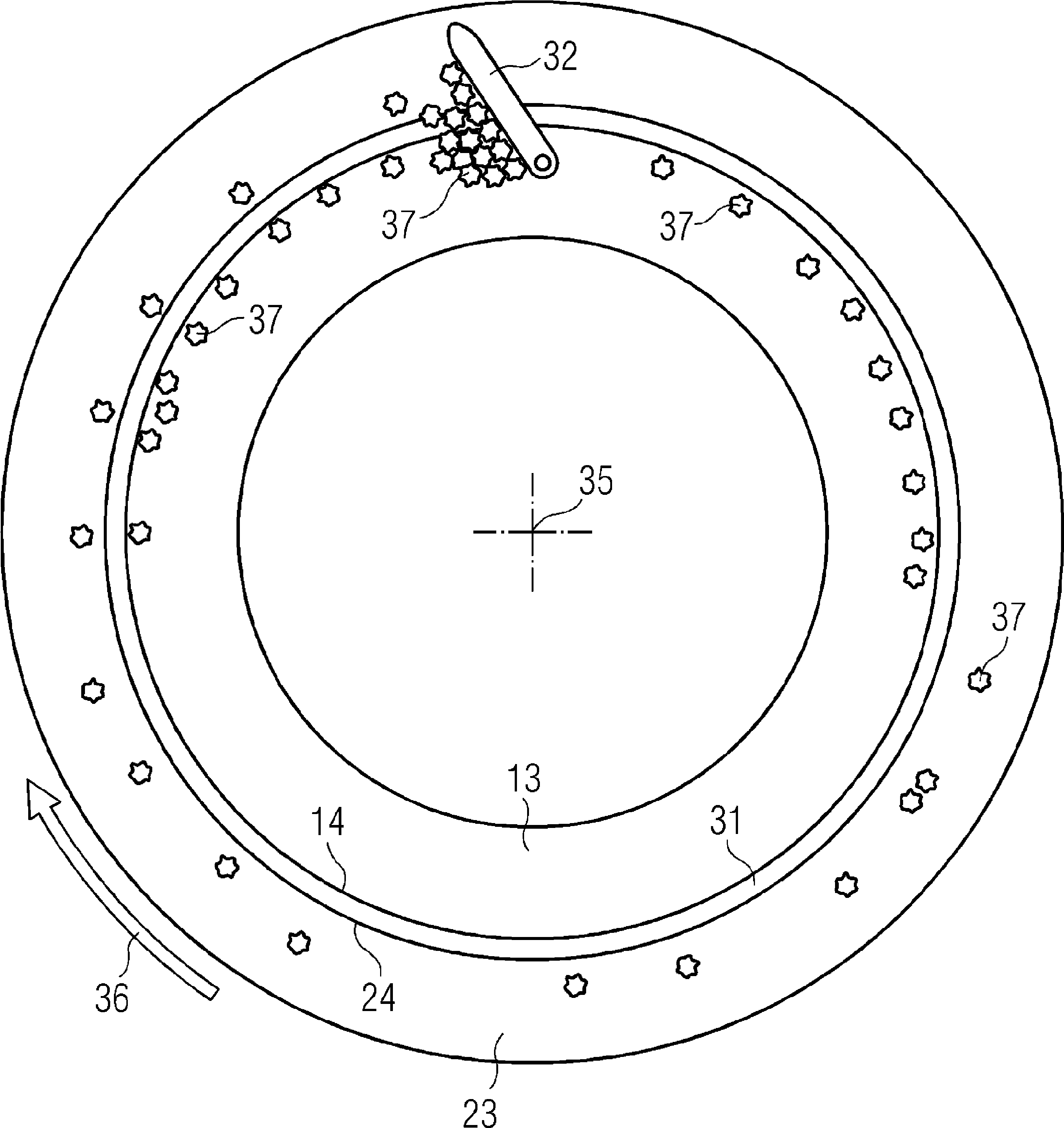

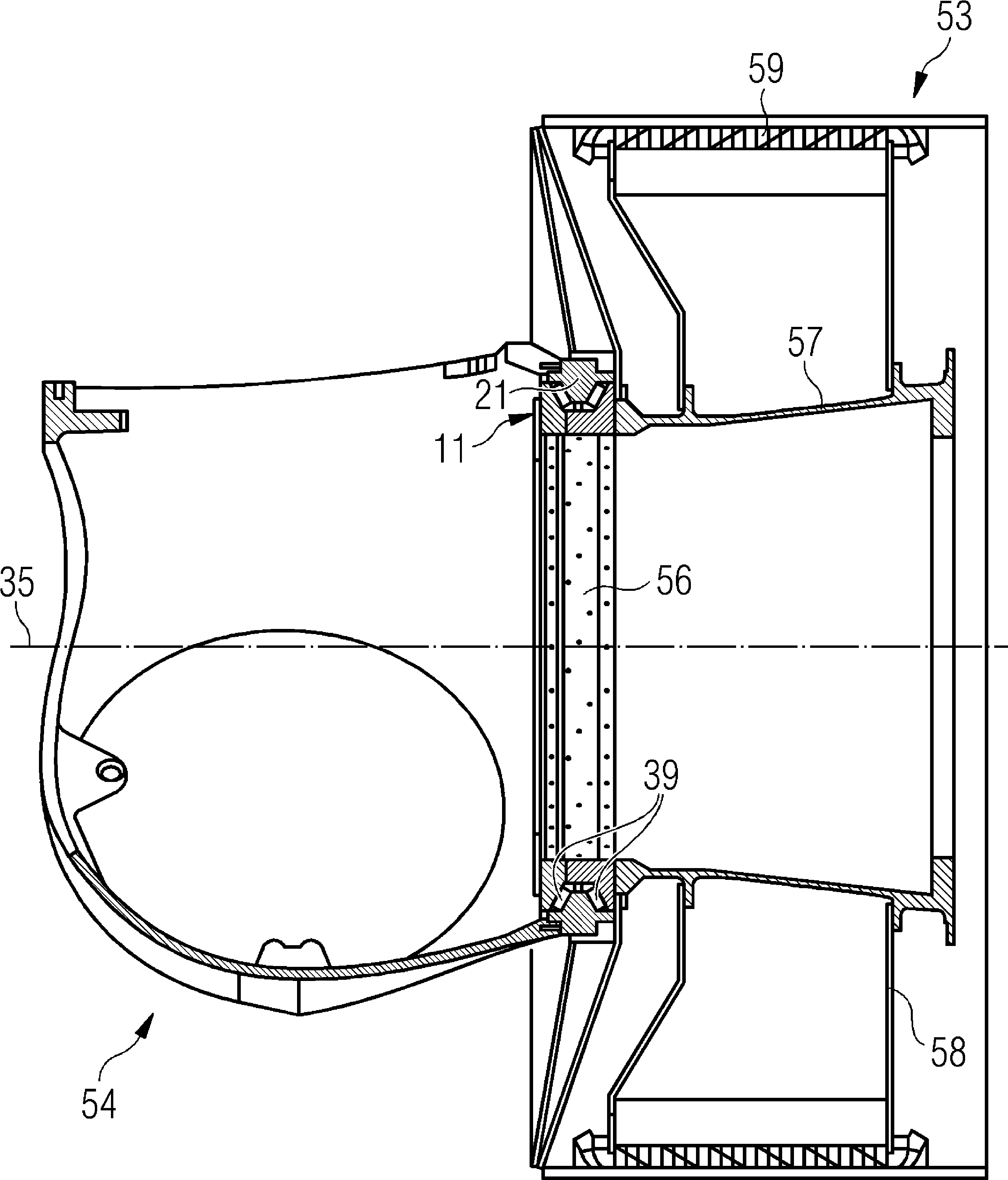

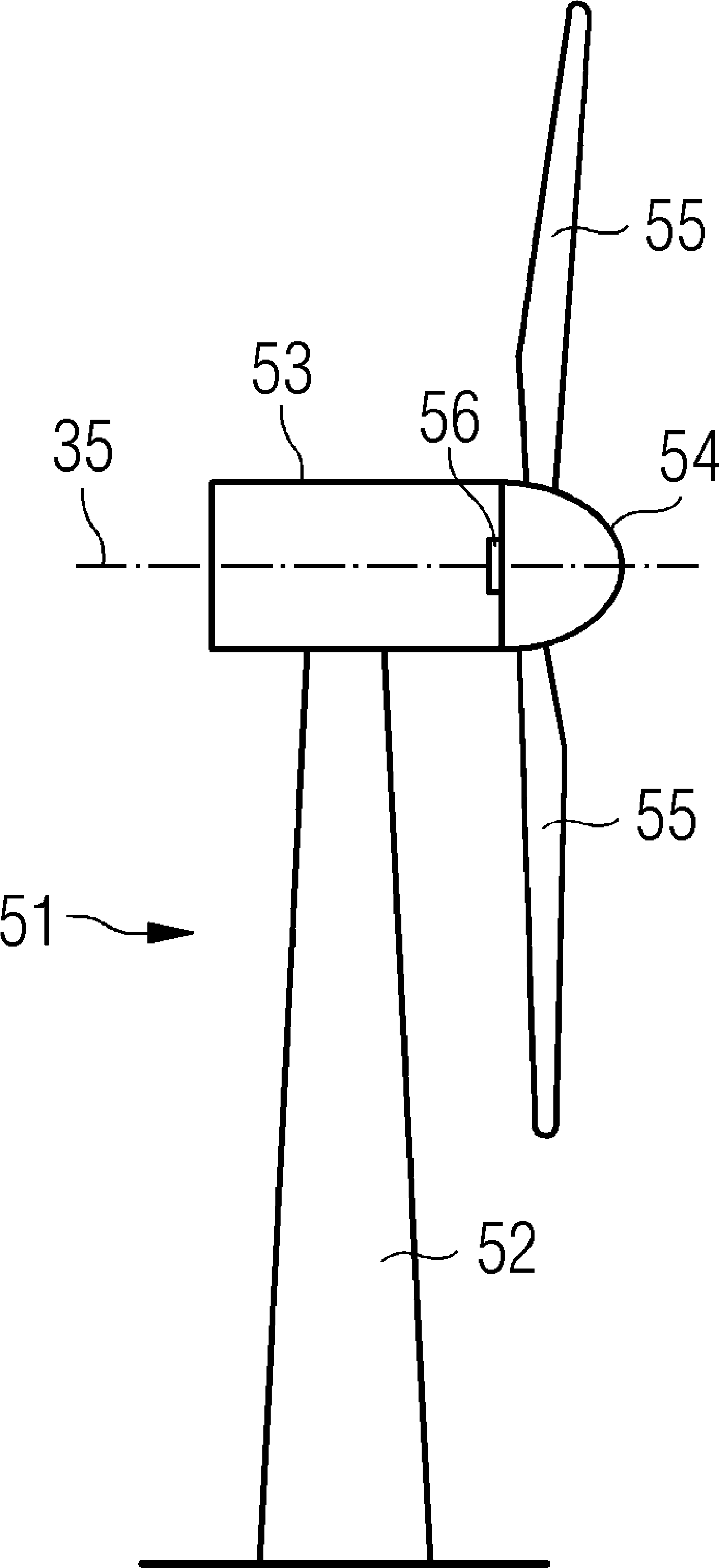

[0074] Figure 1 to Figure 3 A bearing with a lubricant collection system is exemplarily shown.

[0075] figure 1A cross-sectional view of the components of the bearing in a plane parallel to the axis of rotation of the bearing is shown. The bearing comprises a first bearing part 11 with an inner ring and a second bearing part 21 with an outer ring. A first contact surface 12 and a second contact surface 22 can be seen, which are arranged opposite to each other and at a relatively small distance from each other. The portion or region between the contact surfaces 12 , 22 is referred to as the contact portion 31 . The distance between the first bearing edge 14 and the second bearing edge 24 determines the bearing play 33 . Lubricant 37 leaking from the contact portion 31 can leak via the bearing gap 33 , ie along the bearing edges 14 , 24 . The first contact surface 12 forms a first angle 16 with the first front surface 13 ; the second contact surface 22 forms a second angl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com