Cylinder cover used for internal combustion engine

An internal combustion engine and cylinder head technology, applied in the direction of engine cooling, engine components, machines/engines, etc., can solve the problems of excessive heating of the cylinder head, weakening of the sealing effect of the cylinder head and the supercharger, and achieve the effect of ensuring the sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

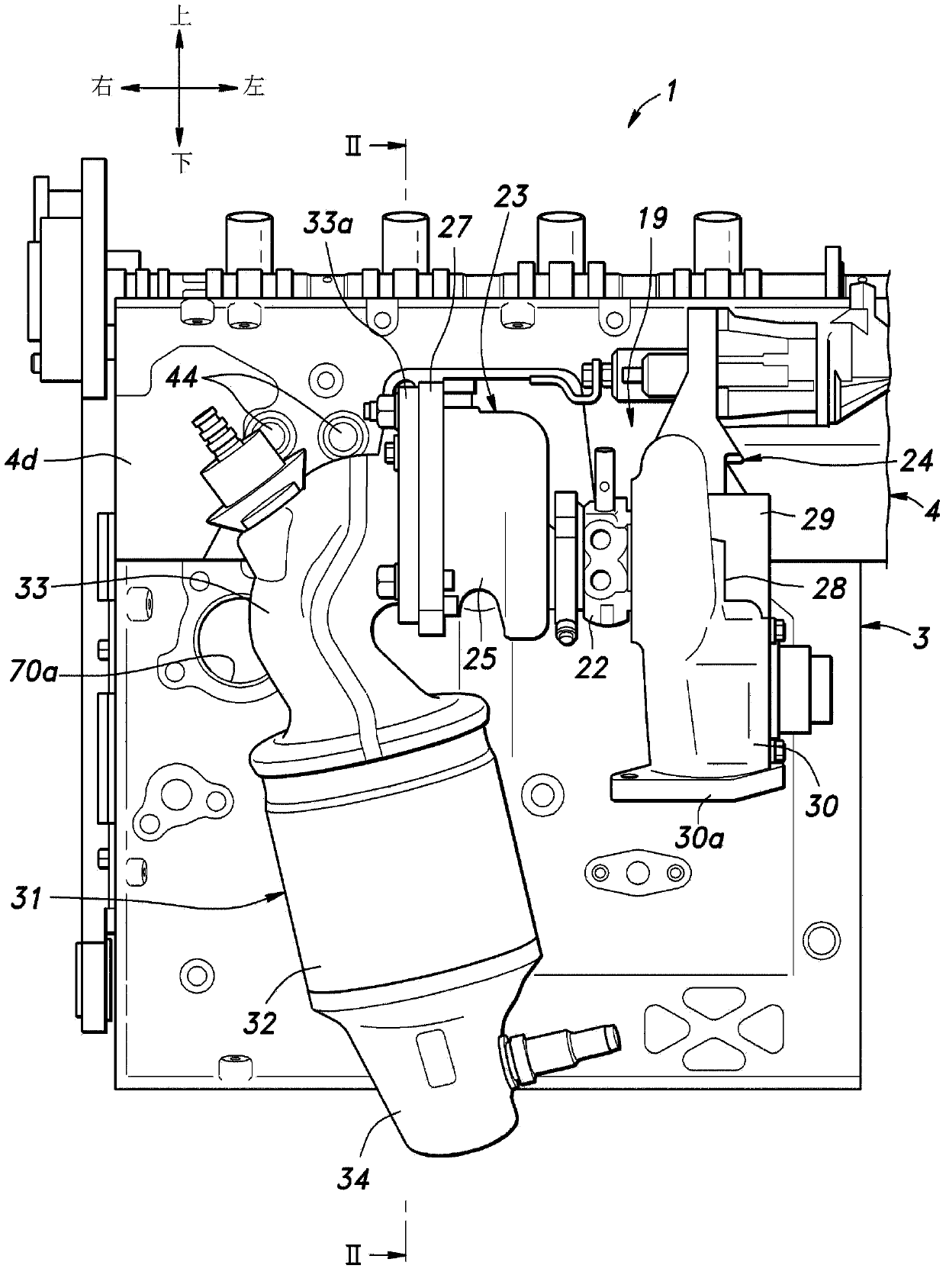

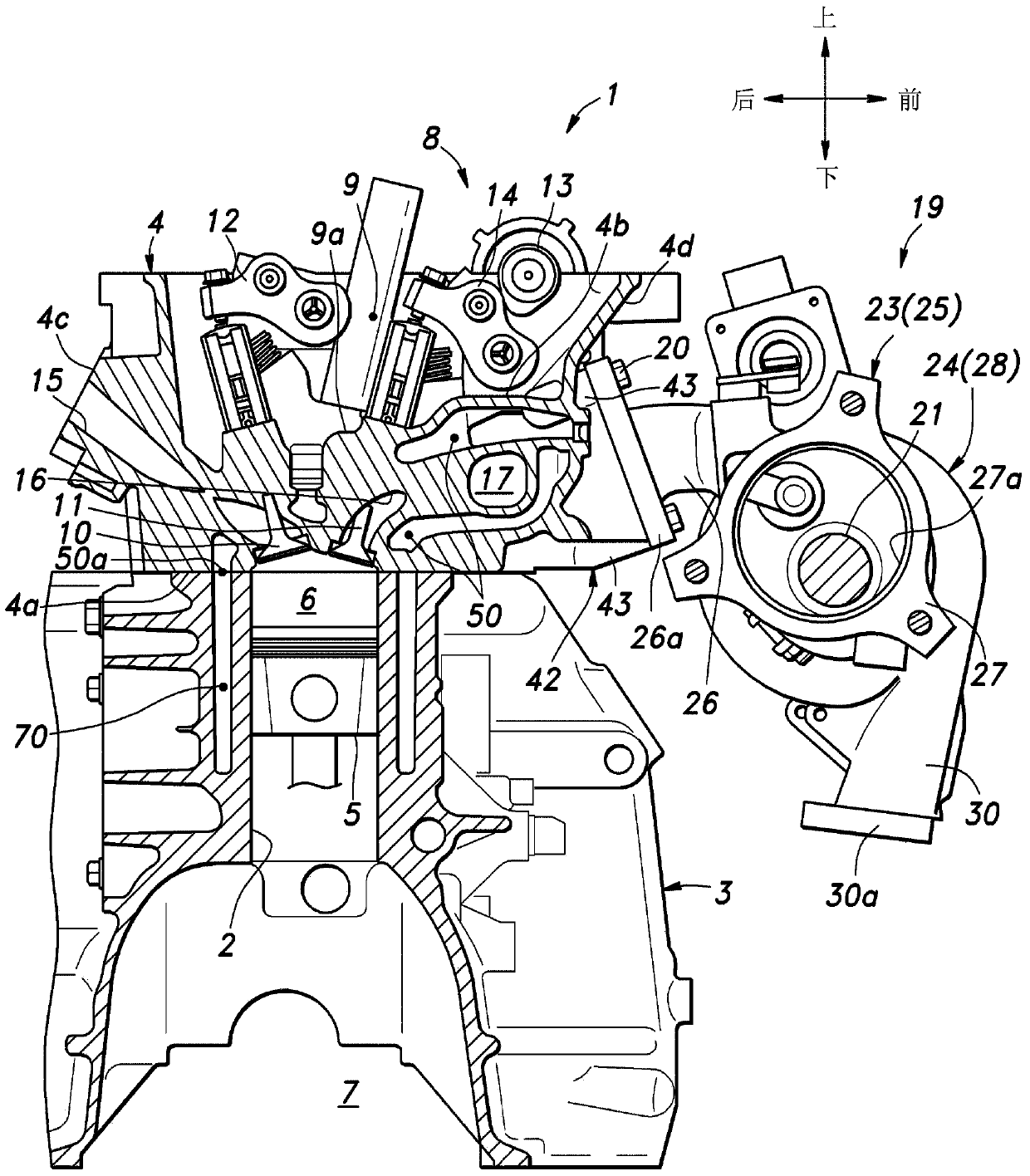

[0044] Such as figure 1 and figure 2 As shown, the engine 1 is mainly composed of a DOHC four-valve inline four-cylinder engine, and includes a cylinder block 3 defining four cylinder bores 2 arranged in a row, and a box-shaped cylinder head 4 attached to the upper surface of the cylinder block 3 , the cylinder head extends perpendicular to the cylinder bore 2 . The cylinder block 3 and the cylinder head 4 are made of die-cast aluminum alloy.

[0045] In the following description, it is assumed that the engine is oriented such that the axis of each cylinder bore 2 (cylinder axis) extends in a vertical vertical direction, and that the exhaust side of the laterally placed engine 1 faces forward. However, the actual orientation of the engine 1 when mounted on a vehicle is not limited by this example. In the following description, for the convenience of description, the vertical direction and the front-to-back direction are defined based on this orientation of the engine 1. ...

no. 2 approach

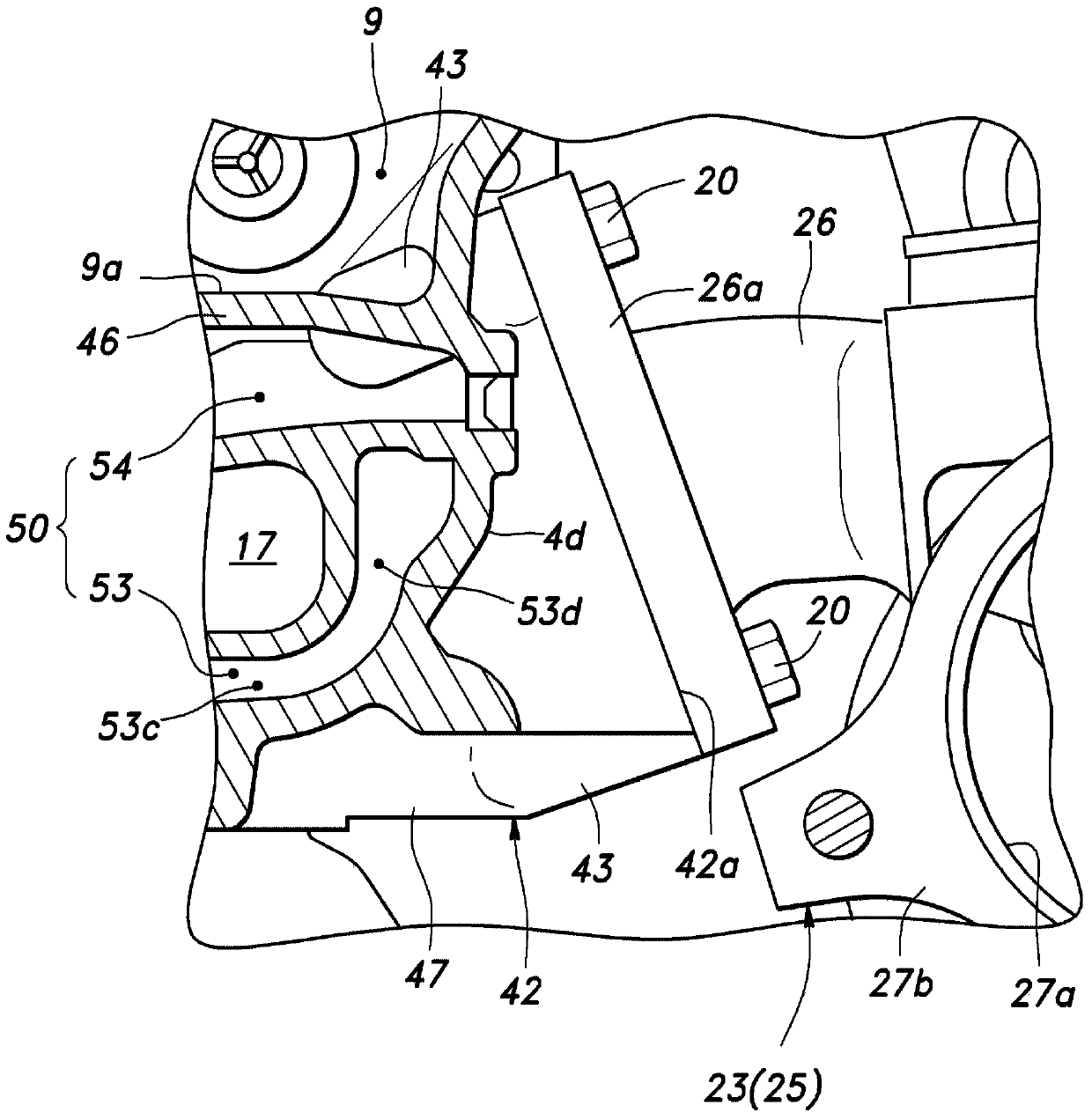

[0108] The following will refer to Figure 18 and Figure 19 A second embodiment of the present invention will be described. exist Figure 18 and Figure 19 In , parts corresponding to those in the first embodiment are designated by like reference numerals, and it is not necessary to repeat description of these parts in the corresponding written description.

[0109] In this embodiment, if Figure 18 As shown, the cooling water inlet 50a of the cylinder head water jacket 50 is more preferably provided on the intake side of each combustion chamber 6 or on the intake side of the main water jacket 51 to a more pronounced extent than in the first embodiment. More specifically, the cooling water inlets 50a arranged on the exhaust side are less and / or smaller than the cooling water inlets 50a arranged on the intake side. That is, the cooling water inlet 50 a is offset toward the intake side of the main water jacket 51 . The expression that the cooling water inlet 50a is "prefe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com