Curtain grouting technology for ore body roof karst fracture development and strong water-rich ore deposit

A curtain grouting and roofing technology, which is applied to mining equipment, shaft lining, tunnel lining, etc., can solve problems such as difficulty in adapting, and achieve the effects of saving drainage costs, significant economic benefits, and reducing mining risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

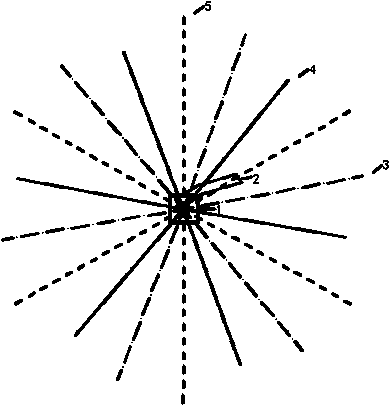

[0039] Depend on figure 1 The vertical projection diagram of the curtain grouting technology of a kind of orebody roof karst fissure development and strong water-rich deposit of the present invention shown and combined figure 2 It can be seen that the roadway 2 is located below the water level line 6, and each chamber 1 is arranged laterally along the roadway 2.

[0040] 1) Arrangement of upward exploration and injection holes: 6 exploration and injection holes at 5°, 15° and 25° are arranged in each chamber 1, forming a drilling control network within 8m×8m. The design of the exploration and injection drilling holes is based on the center of the chamber, and the six 5° exploration injection holes 3, the six 15° exploration injection holes 4, and the six 25° exploration injection holes 5 are evenly arranged on the plane staggered by 60°. 50...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com