Side face snow plow for land leveller

一种平地机、雪犁的技术,应用在雪面清洗、移土机/挖土机、机械驱动的挖掘机/疏浚机等方向,能够解决不稳、重心前移、路面伤害等问题,达到增加单程除雪宽度、避免重心前倾、减少打滑的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

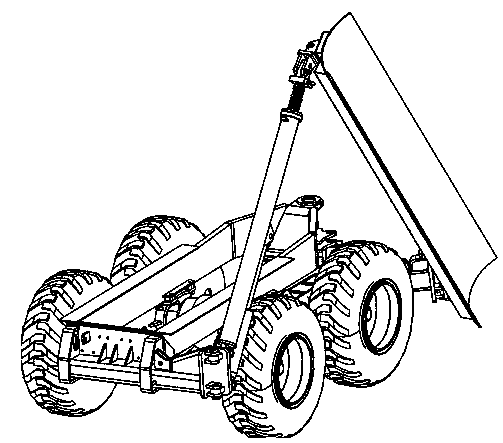

[0020] The present invention will be further described below in conjunction with accompanying drawing.

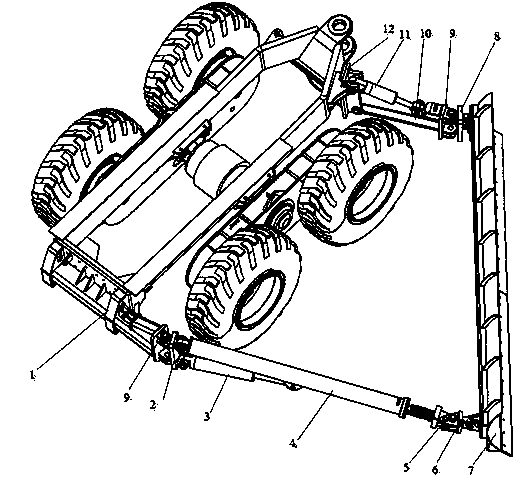

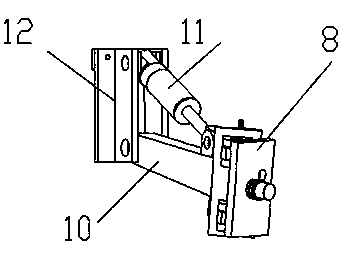

[0021] like figure 1 As shown, the side snow plow for a motor grader of the present invention includes a rear mounting seat 1, a hydraulic cylinder I3, a tie rod body 4, a snow pusher 7, a swing rod 10, a hydraulic cylinder II11 and a front mounting seat 12; the rear mounting seat 1 is fixed on At the rear end of the rear frame of the motor grader, the rear mounting seat 1 is hinged to the hinge plate I2 through the pin shaft 9; one end of the tie rod body 4 is hinged to the hinge plate I2 through the pin shaft, and the other end is hinged to the hinge plate II6 through the fixed pin shaft 5; One end of the oil cylinder I3 is hinged with the rear mounting base 1, and the other end is hinged with the tie rod body 4; the front mounting base 12 is fixed at the front end of the rear frame of the motor grader; There is a hinged plate III8; one end of the hydraulic cylinder II11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com