Modified filler and preparation method thereof, pulp stock applying modified filler and paper

A modification and slurry technology, which is applied in the post-treatment modification of paper and cellulose pulp, papermaking, etc., can solve the problems of poor retention rate and hinder the bonding force between fibers and fibers, and achieve easy film formation and increase bonding force , the effect of high surface negative charge density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0017] A method for preparing a slurry, comprising the steps of:

[0018] (1) Preparation of nanocellulose modified filler.

[0019] Add NFC to the filler dispersion (mass percentage concentration is 10%-50%), and stir for 5-15 minutes to obtain nano-cellulose modified filler, wherein the dry weight of NFC is 0.1%-20% of the dry weight of the filler , preferably 0.1%-10% of the dry weight of the filler.

[0020] The carboxyl group content on the surface of the NFC is 0.05-1.5 mmol / g, preferably 0.1-1.0 mmol / g.

[0021] The surface Zeta potential of the filler is greater than or equal to 0, specifically, it can be a paper-making filler such as precipitated calcium carbonate (PCC), ground calcium carbonate (GCC), kaolin, talc, preferably PCC, kaolin, and talc.

[0022] The NFC has a strongly negative charge on the surface, the filler particles have a zeta potential greater than 0mv, and the surface is positively charged. Due to the mutual attraction of positive and negative ch...

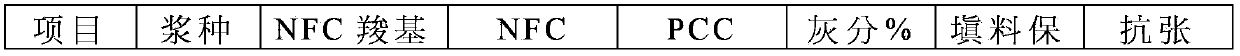

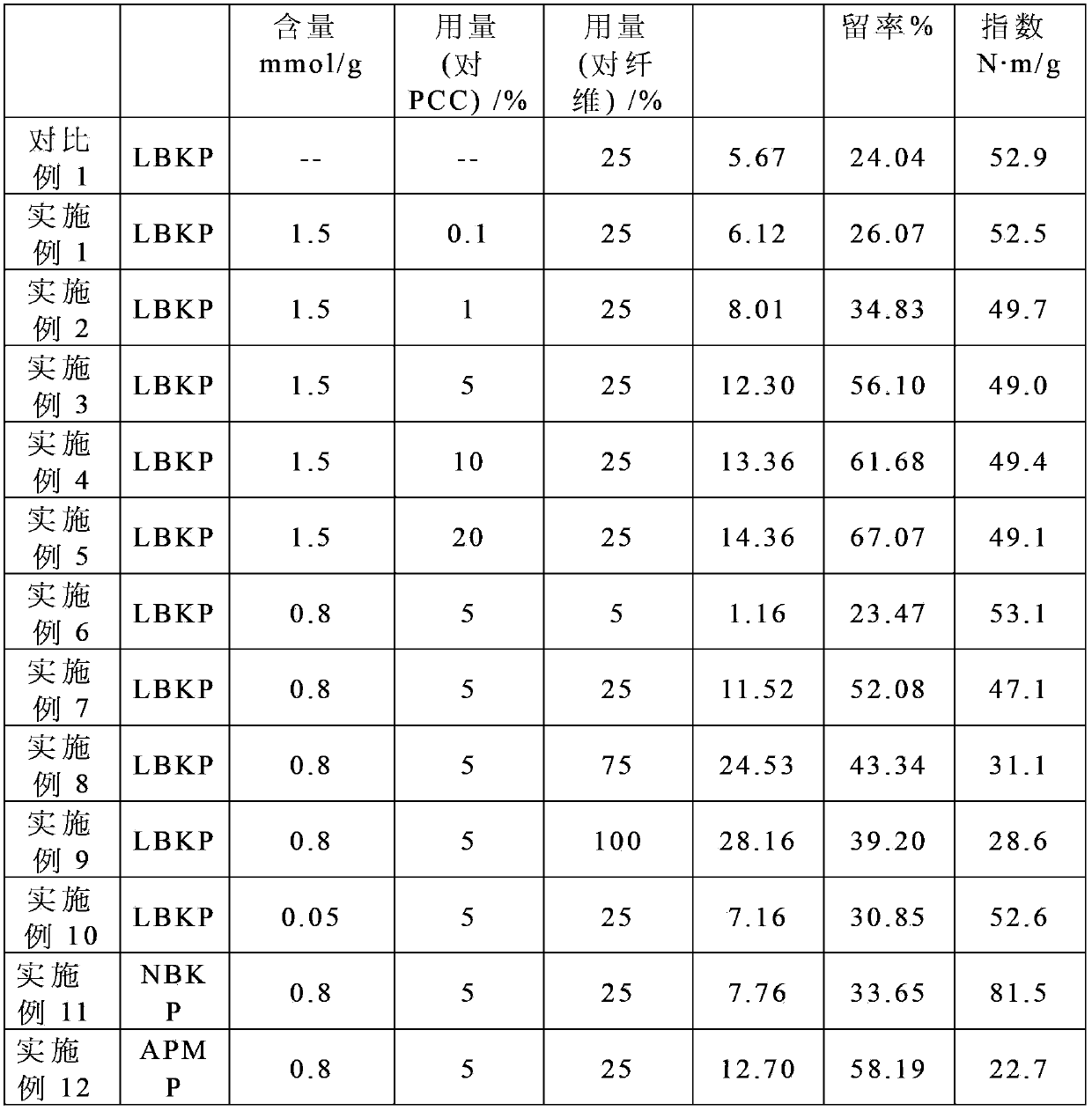

Embodiment 1

[0033] NFC with a carboxyl content of 1.5mmol / g was used to modify PCC, and the amount of NFC was 0.1% of the dry PCC mass. The modified PCC was added to the LBKP slurry, the quality of the added PCC was 25% of the dry weight of the LBKP pulp, and 0.8% of the cationic starch was added to the dry weight of the LBKP pulp. After stirring evenly, the sheets were made. The ash content of the finished paper was 6.12%, the filler retention rate was 26.07%, and the tensile strength was 52.5N·m / g.

Embodiment 2

[0035] PCC was modified by NFC with a carboxyl content of 1.5 mmol / g, and the amount of NFC was 1% of the dry PCC mass. The modified PCC was added to the LBKP slurry, the quality of the added PCC was 25% of the dry weight of the LBKP pulp, and 0.8% of the cationic starch was added to the dry weight of the LBKP pulp. After stirring evenly, sheet is made. The ash content of the finished paper is 8.01%, the filler retention rate is 34.83%, and the tensile strength is 49.7N·m / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| retention rate | aaaaa | aaaaa |

| retention rate | aaaaa | aaaaa |

| retention rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com