Cutting machine with cloth automatically laid smooth

A cutting machine and automatic technology, applied in the cutting of textile materials, textiles and papermaking, etc., can solve the problems of high labor intensity, time-consuming and labor-intensive cloth, and cannot meet the mass production of the assembly line.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

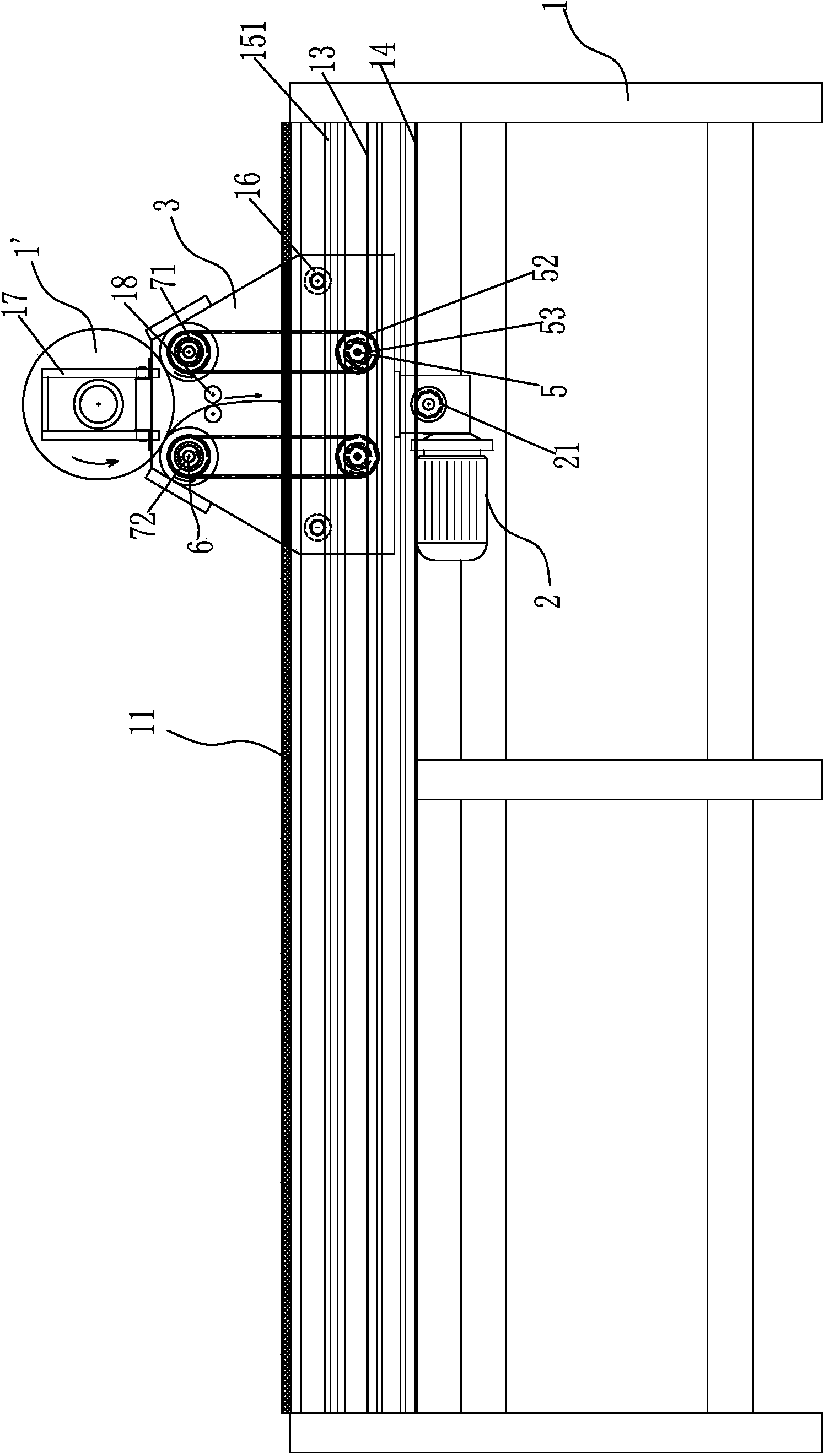

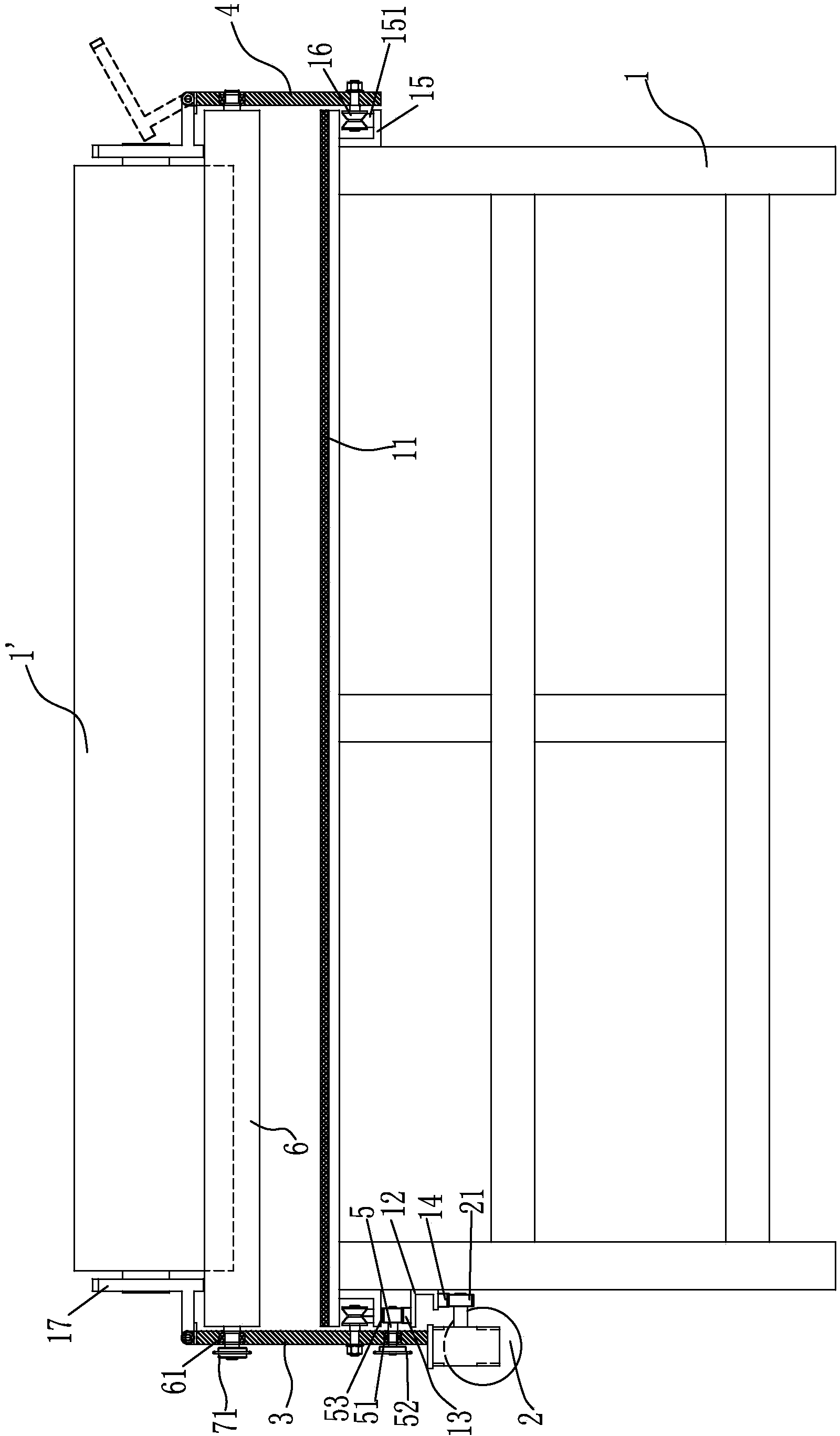

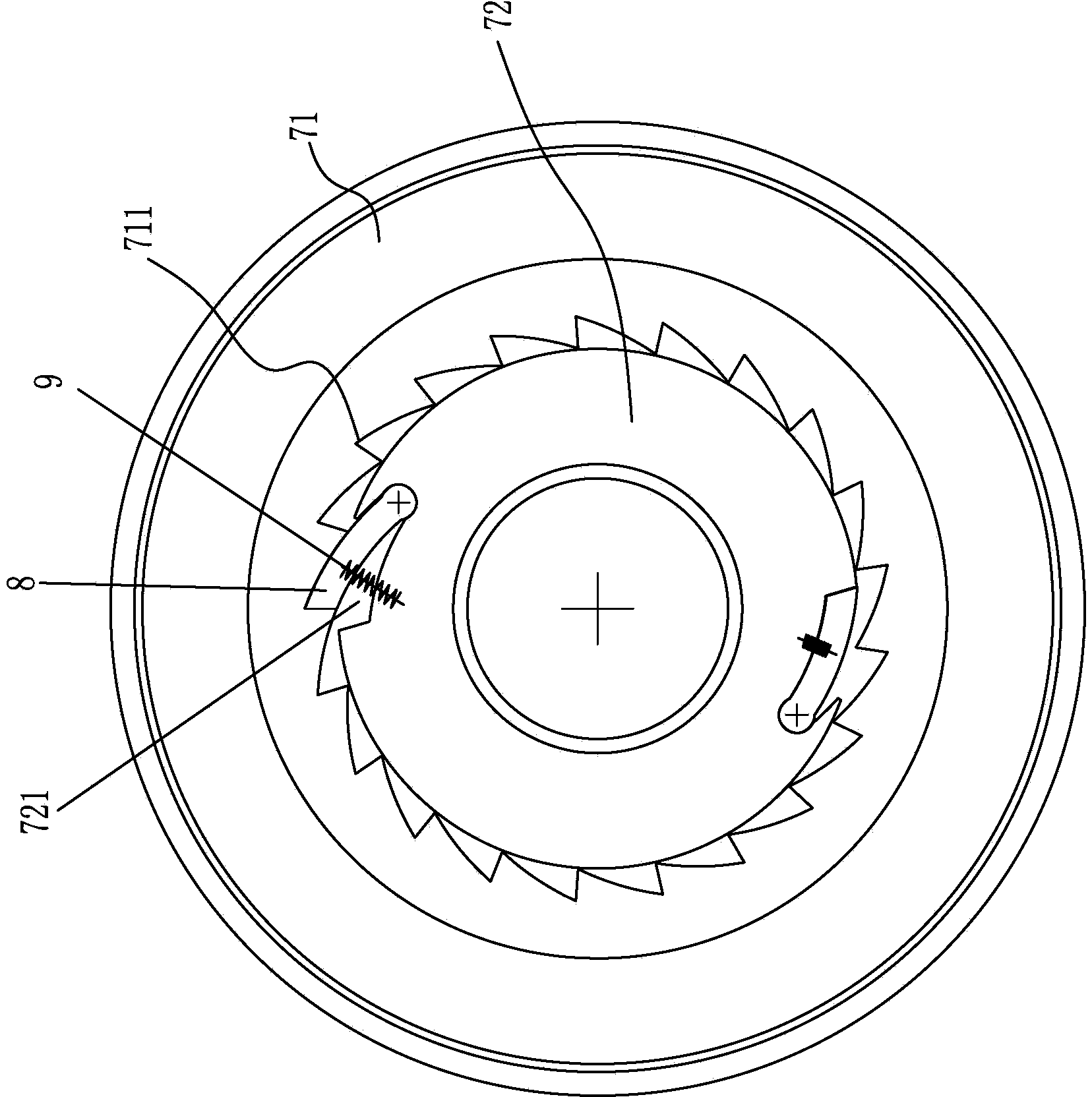

[0017] refer to figure 1 with image 3 , the present embodiment discloses a cloth automatic flattening and cutting machine, comprising a frame 1, a gear motor 2, a left wall panel 3, a right wall panel 4, and left and right cloth guide wheel groups. There is a cutting plate 11, and one side of the frame 1 is fixed with a tooth row seat 12, and the upper and lower sides of the tooth row seat 12 are respectively fixed with an upper tooth row 13 and a lower tooth row 14, and the left wallboard 3 is located on one side of the frame 1 and can slide left and right along the side of the frame 1. The deceleration motor 2 is fixed under the left wallboard 3, and the output shaft of the deceleration motor 2 is provided with a travel gear 21. The gear 21 meshes with the lower row of teeth 14, and the left wall board 3 is located on the top of the gear row seat 12, and the left and right sides are respectively rotatably provided with driving shafts 5. Between the driving shafts 5 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com