A kind of yellow rice wine brewing method that reduces the higher alcohol content of yellow rice wine

A technology of rice wine brewing and alcohol content, applied in the direction of microorganism-based methods, preparation of alcoholic beverages, biochemical equipment and methods, etc., can solve the problems of low alcohol fermentation capacity, poor selectivity, low alcohol content of rice wine, etc., and achieve reduction of abnormalities Miscellaneous odor and its damage to the human nervous system, the effect of reducing the content of higher alcohols and enhancing comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

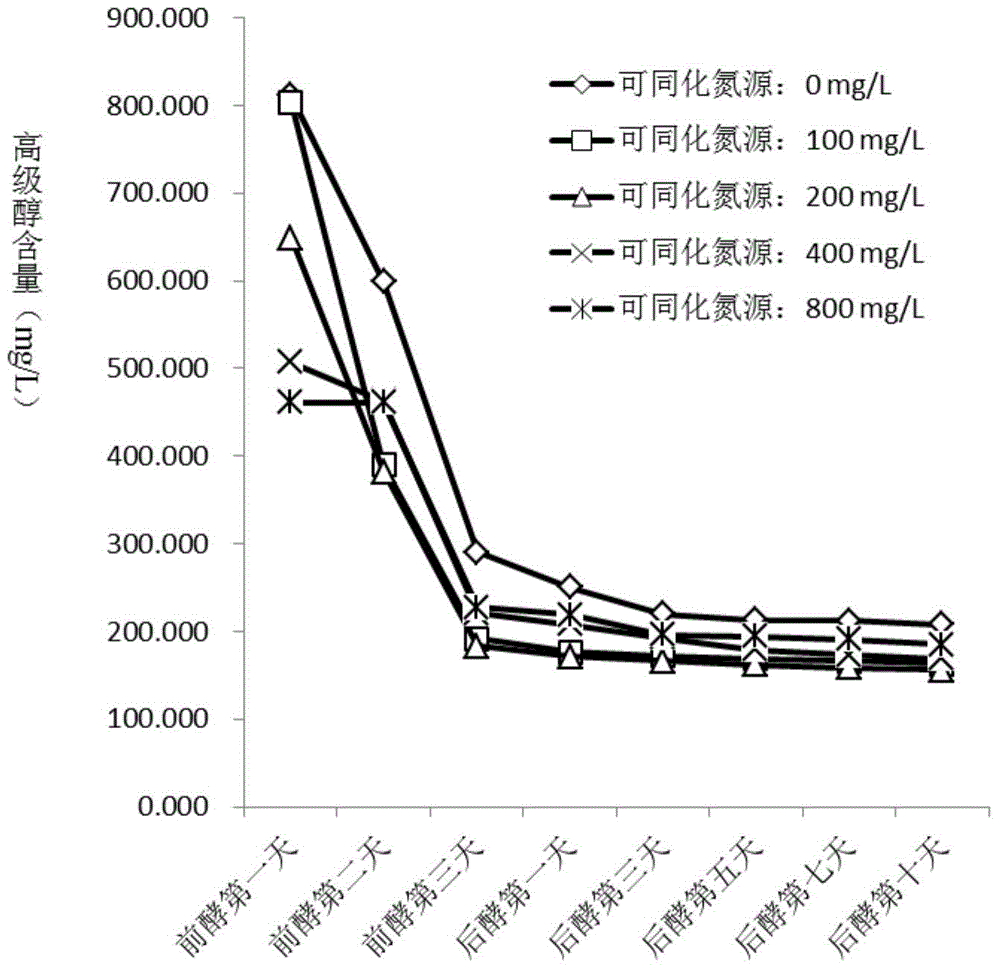

[0028] Embodiment 1 different assimilable nitrogen source addition amount

[0029] The rice wine brewing method for reducing the content of higher alcohols in rice wine with different additions of assimilable nitrogen sources comprises the following steps:

[0030] (1) Soaking rice: Soak glutinous rice in water, the ratio of material to water is 1:0.9-1:2.3, and the soaking time does not exceed 24 hours;

[0031] (2) Steamed rice: Rinse the soaked glutinous rice and cook until soft and rotten without white heart;

[0032] (3) Drain the rice: rinse the steamed glutinous rice with water, cool and drain;

[0033] (4) Putting into the tank: Transfer the glutinous rice after pouring rice into the brewing tank, add water and mix according to the material-to-water ratio of 1:0.9-1:2.3.

[0034] (5) Saccharification: Use food-grade lactic acid to adjust the pH to 4.2-4.5, and add 100-150 U / g of glucoamylase;

[0035] (6) Fermentation: add 10mg / 100mL) of wheat koji, 5% (v / v) activat...

Embodiment 2

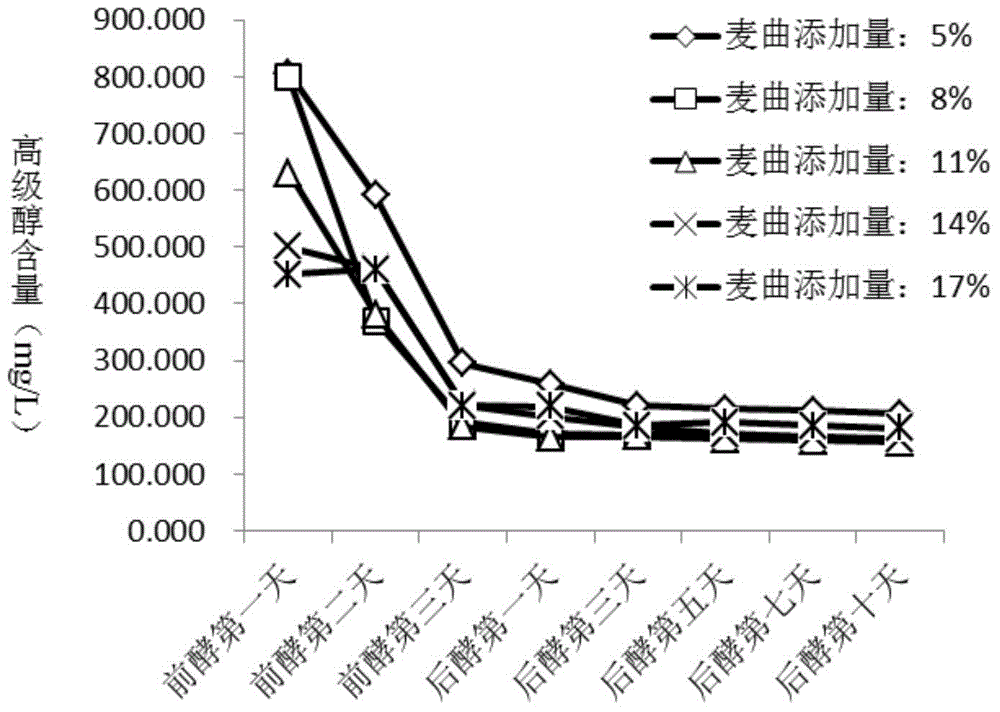

[0039] Embodiment 2 different wheat koji additions

[0040] The yellow rice wine brewing method that different wheat koji additions reduce the higher alcohol content in yellow rice wine comprises the following steps:

[0041] (1) Soaking rice: Soak glutinous rice in water, the ratio of material to water is 1:0.9-1:2.3, and the soaking time does not exceed 24 hours;

[0042] (2) Steamed rice: Rinse the soaked glutinous rice and cook until soft and rotten without white heart;

[0043] (3) Drain the rice: rinse the steamed glutinous rice with water, cool and drain;

[0044] (4) Putting into the tank: Transfer the glutinous rice after pouring rice into the brewing tank, add water and mix according to the material-to-water ratio of 1:0.9-1:2.3.

[0045] (5) Saccharification: Use food-grade lactic acid to adjust the pH to 4.2-4.5, and add 100-150 U / g of glucoamylase;

[0046] (6) Fermentation: add 5%-20% (m / v: mg / mL) wheat koji, 5% (v / v) activated rice wine dry yeast solution, 10...

Embodiment 3

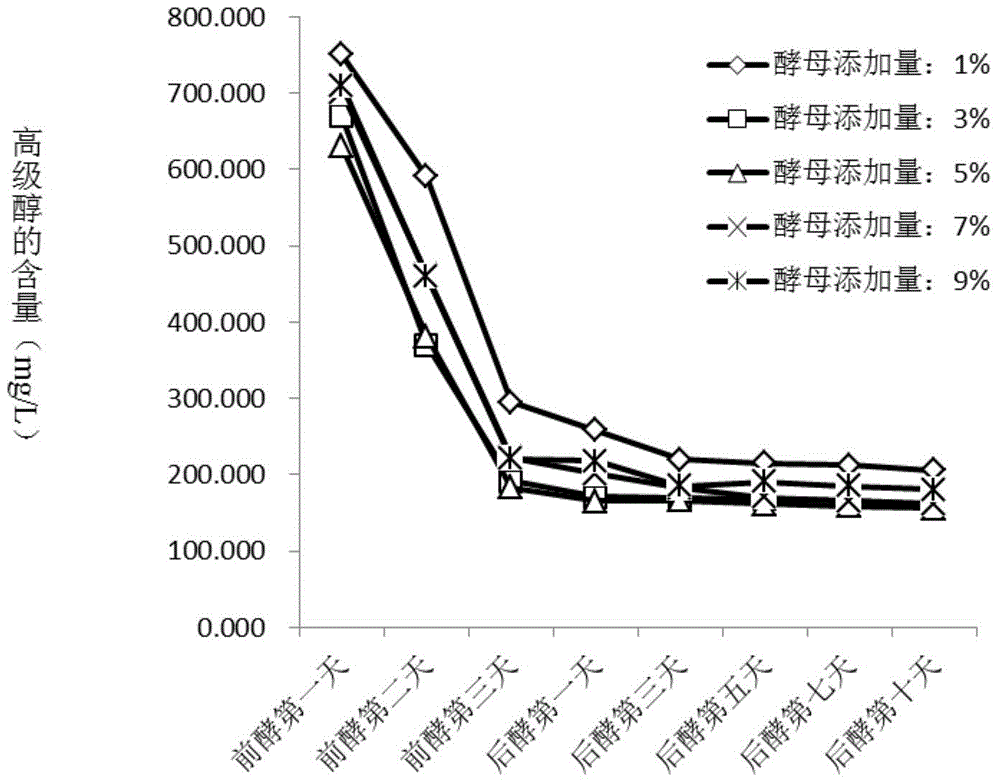

[0050] Embodiment 3 different yeast additions

[0051] A rice wine brewing method for reducing the content of higher alcohols in rice wine with different yeast additions, comprising the following steps:

[0052] (1) Soaking rice: Soak glutinous rice in water, the ratio of material to water is 1:0.9-1:2.3, and the soaking time does not exceed 24 hours;

[0053] (2) Steamed rice: Rinse the soaked glutinous rice and cook until soft and rotten without white heart;

[0054] (3) Drain the rice: rinse the steamed glutinous rice with water, cool and drain;

[0055] (4) Putting into the tank: Transfer the glutinous rice after pouring rice into the brewing tank, add water and mix according to the material-to-water ratio of 1:0.9-1:2.3.

[0056] (5) Saccharification: Use food-grade lactic acid to adjust the pH to 4.2-4.5, and add 100-150 U / g of glucoamylase;

[0057] (6) Fermentation: add 10% (m / v: mg / mL) wheat koji, 1%-10% (v / v) activated rice wine dry yeast solution, 100mg / L assimilab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com