MTO (methanol toolefin) and steam crackingto olefin mixed separation technology

A methanol-to-olefins and olefins-to-olefins technology, applied in distillation purification/separation, hydrocarbon purification/separation, hydrocarbon cracking to hydrocarbons, etc., can solve the problems of high cost of olefins and high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

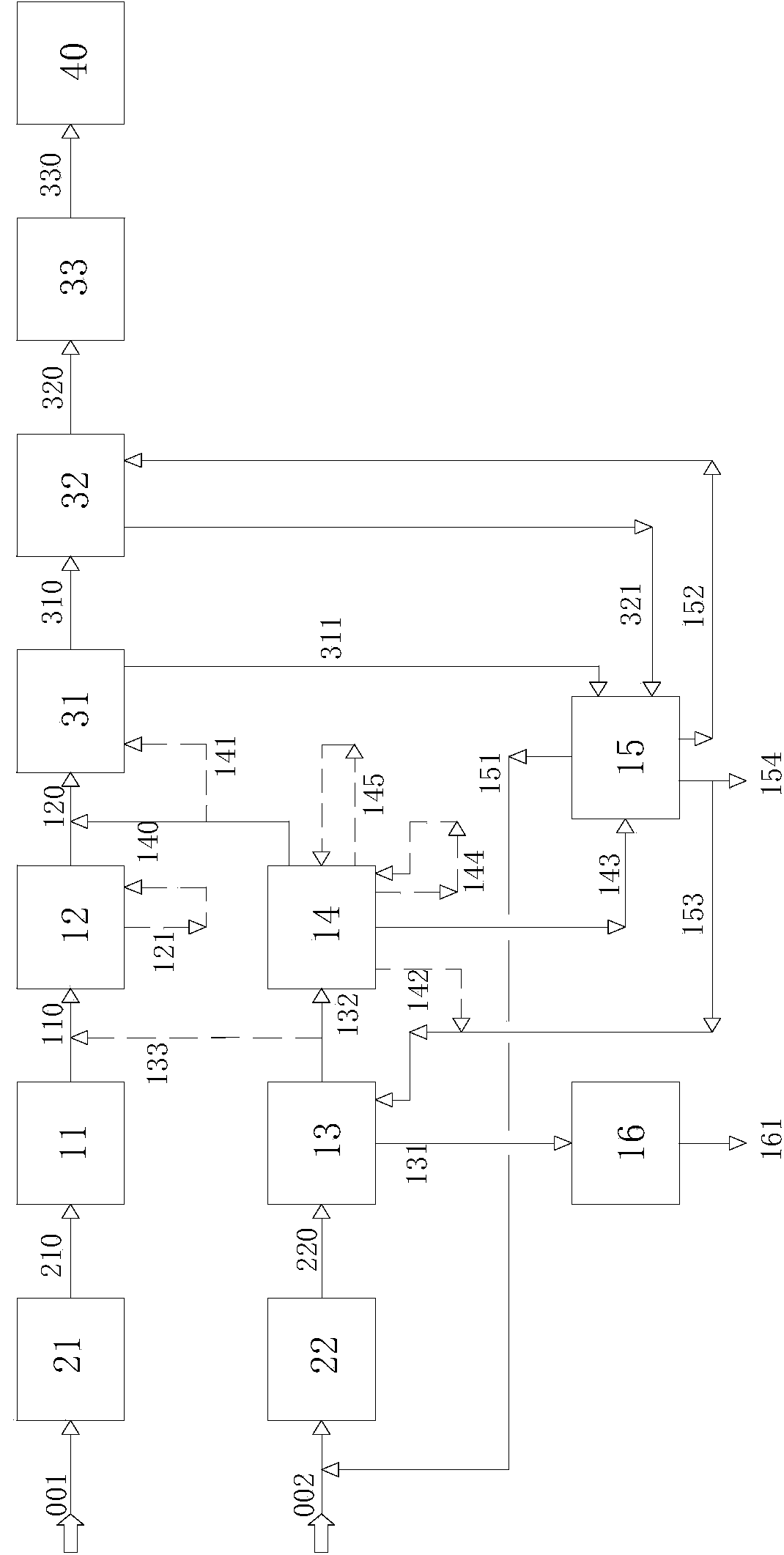

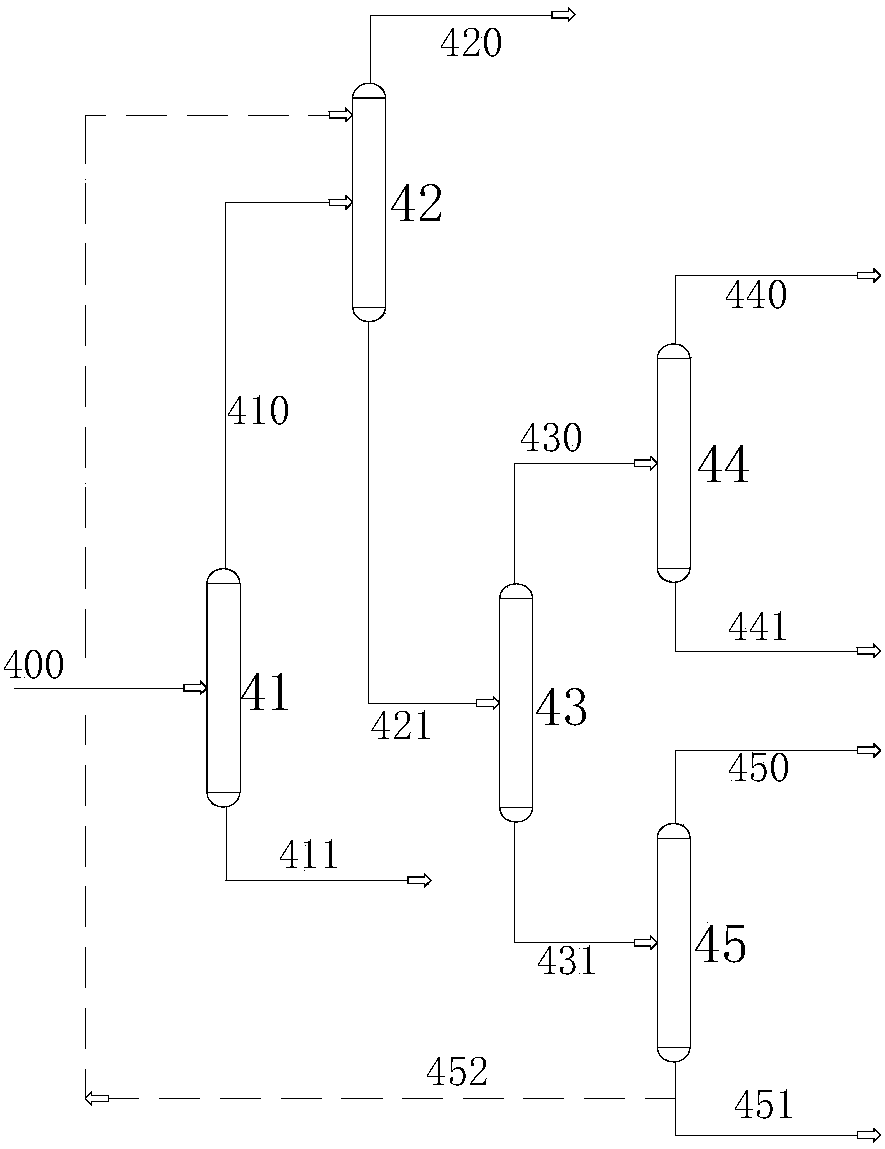

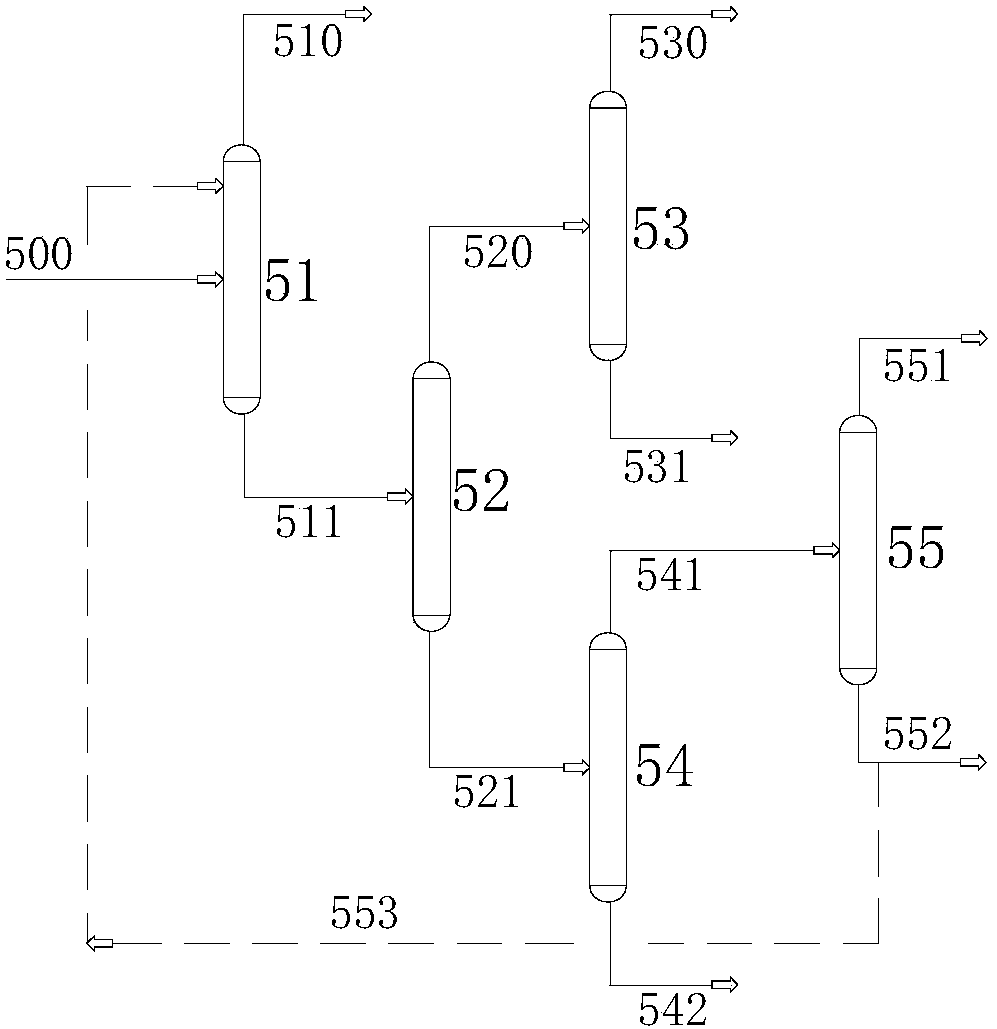

[0024] process flow figure 1 process shown. The main equipment includes cracking furnace 21; quenching oil tower 11; quenching water tower 12; compressor one stage and compressor two stage 31; washing tower 32; alkali washing tower 33; compressor three stages, compressor four stages or compressor five stages and Separation system 40; methanol to olefins reactor 22; quenching tower 13; water washing tower 14; catalyst-containing sewage treatment equipment 16; oxide stripping tower 15; figure 2 The main equipment includes depropanizer 41; pre-cut tower and oil absorption tower 42; deethanizer 43; ethylene tower 44; propylene tower 45; image 3 The main equipment includes demethanizer 51; deethanizer 52; ethylene tower 53; depropanizer 54; propylene tower 55; Figure 4 The main equipment includes deethanizer 61; demethanizer 62; ethylene tower 63; depropanizer 64; propylene tower 65 and various pipelines.

[0025] The process flow is as follows:

[0026] Gasified or preheate...

Embodiment 2

[0031] The methanol-to-olefins reaction gas passes through the quenching tower 13, and then the stream 133 directly goes to the quenching water tower 12, mixes with the reaction gas from hydrocarbon thermal cracking to produce olefins, and then enters the quenching water tower 12, and then goes to the first stage of the compressor, the second stage of the compressor 31, and the washing tower 32, The alkali washing tower 33 and the separation system 40 can cancel the water washing tower 14 in the methanol-to-olefins process.

Embodiment 3

[0033] If the reaction pressure of methanol to olefins is relatively high, the methanol to olefins reaction gas passes through the water washing tower 14, and the stream 141 can directly go to the second stage of the compressor before mixing with the reaction gas of hydrocarbon thermal cracking to olefins, enter the second stage of the compressor, and then go to the second stage of the compressor for washing Tower 32 , alkali washing tower 33 , three-stage compressor, four-stage compressor or five-stage compressor and separation system 40 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com