Processing device for cationic dye wastewater and wastewater processing method of processing device

A cationic dye and wastewater treatment technology, which is applied in textile industry wastewater treatment, water/sewage multi-stage treatment, adsorption water/sewage treatment, etc., can solve the problems of difficult treatment and utilization of sediment, water hypoxia, consumption, etc., and achieve good results The value of promotion and application, the addition of less medicine, and the effect of improving the decolorization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] The present invention is described in detail below, but the protection scope of the present invention is not limited to the examples described.

[0048] Utilize the cationic dye wastewater treatment device provided by the present invention to process the dye wastewater taken from a certain dye chemical factory in Tianjin. The wastewater of this factory mainly produces cationic dyes. The specific device is as follows:

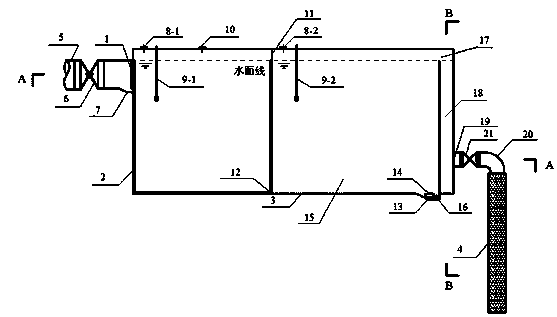

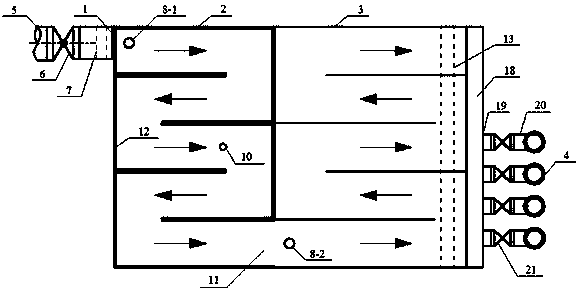

[0049] Such as figure 1 As shown, the schematic diagram of the cationic dye wastewater treatment device provided for this implementation includes a primary filter grid 1, an electrolytic cell 2, a sedimentation tank 3 and an activated carbon column 4, wherein the primary filter grid 1 is arranged at the water inlet of the electrolytic cell 2 (Such as image 3 ), the electrolytic cell 2 is connected to the sedimentation tank 3, the water outlet 11 of the electrolytic cell is the water inlet of the sedimentation tank 3, and the water outlet 19 of the sedi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com